Microsensor capable of being embedded in movable part in cavity

A technology of miniature sensors and moving parts, which is applied in the field of sensors in the detection technology field. It can solve the problems that the sensing signal cannot be transmitted, shielded, and the sensor cannot be equipped with a data transmission line. It achieves good dynamics and followability, and facilitates data processing. , the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

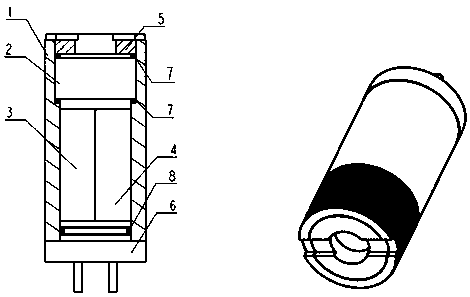

[0030] Combine below Figure 1 to Figure 5 Describe the embodiments of the present invention in detail:

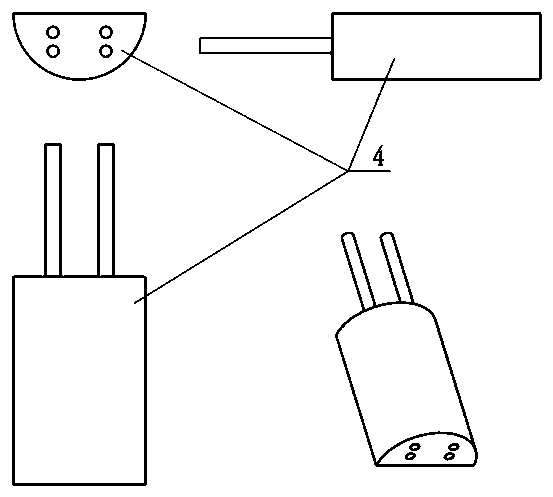

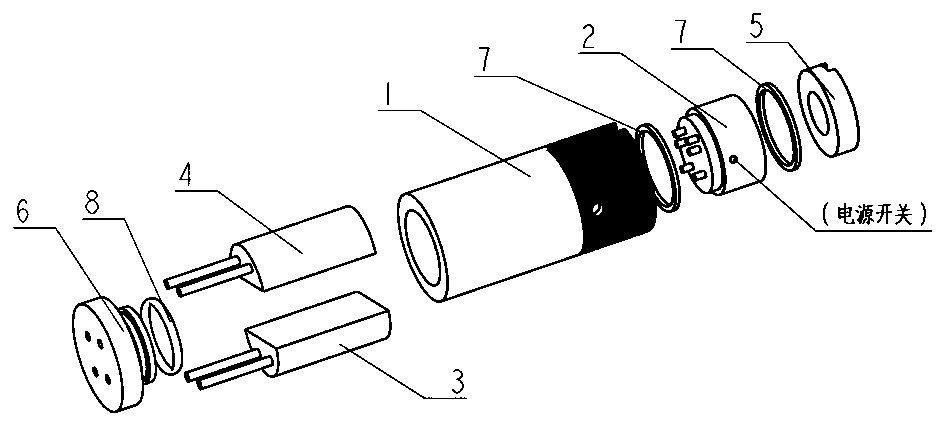

[0031] The invention discloses a miniature sensor that can be embedded on a moving part in a cavity, including: a housing (1), a sensing element (2), a battery (3), an integrated chip (4), a front cover (5) and a back cover (6); The housing (1) is made of metal, with external and internal threads at the front end, and a stepped hole inside; the sensing element (2) is a stepped cylindrical shape, and is installed in the housing (1) thread one In the stepped hole on the side, a ring gasket (7) is installed between the stepped hole and the stepped hole step. There are two sets of pins at the rear end, which are a two-pin set and a four-pin set. The pins of the two-pin set and the battery ( 4) Socket connection, supply power to the sensor element (2), and at the same time connect with two pins in the four-pin group to supply power to the integrated chip (4), the other two pins i...

Embodiment 2

[0039] Combine below Image 6 The second embodiment of the present invention is described in detail: a miniature sensor that can be embedded on the moving part in the cavity, and its structure is improved from the first embodiment. The improvement lies in the situation where the shielding of wireless information transmission is not serious and the quality of signal wireless transmission is guaranteed, the integrated chip (4) has two construction methods. The first way is that the integrated chip (4) integrates an A / D conversion circuit, a control circuit, a writing circuit, a storage unit, a readout circuit, a crystal oscillator circuit, and a wireless transceiver circuit; the control circuit uses the wireless transceiver The circuit receives the control signals for the start and end of data storage, and can accurately control the timing of signal collection; the wireless transceiver circuit has the function of receiving external control information and transmitting the stored d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com