Polymeric kettle and thermal withdrawal mode thereof

A technology of polymerization kettle and kettle body, which is applied in the field of intermittent liquid-phase bulk polypropylene polymerization kettle and its external circulation heat removal method, which can solve the problems of shortening the reaction time, large-scale polymerization kettle and insufficient heat removal capacity, etc., and achieves Improve the output of single kettle, improve the effect of heat removal, and improve the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

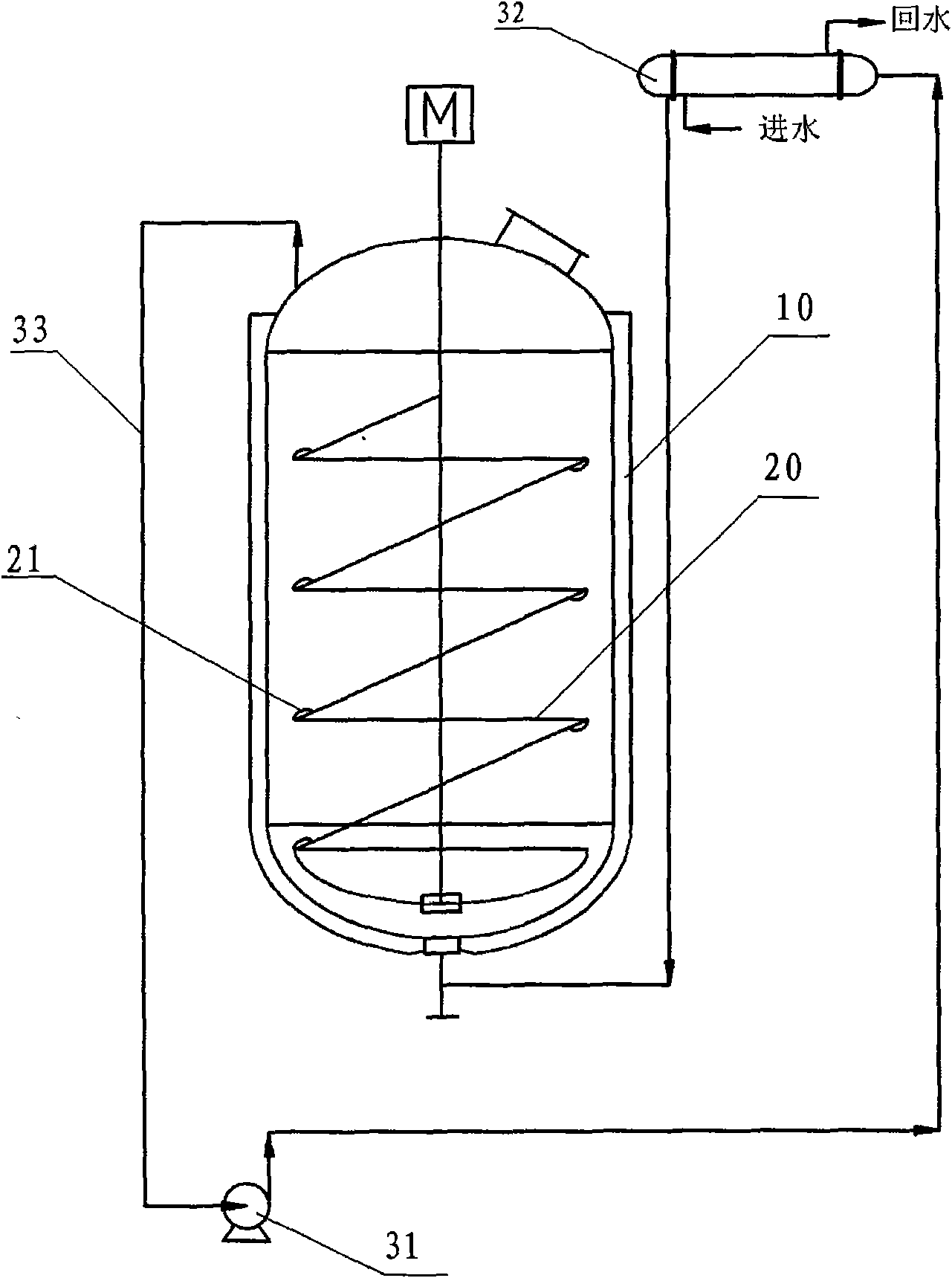

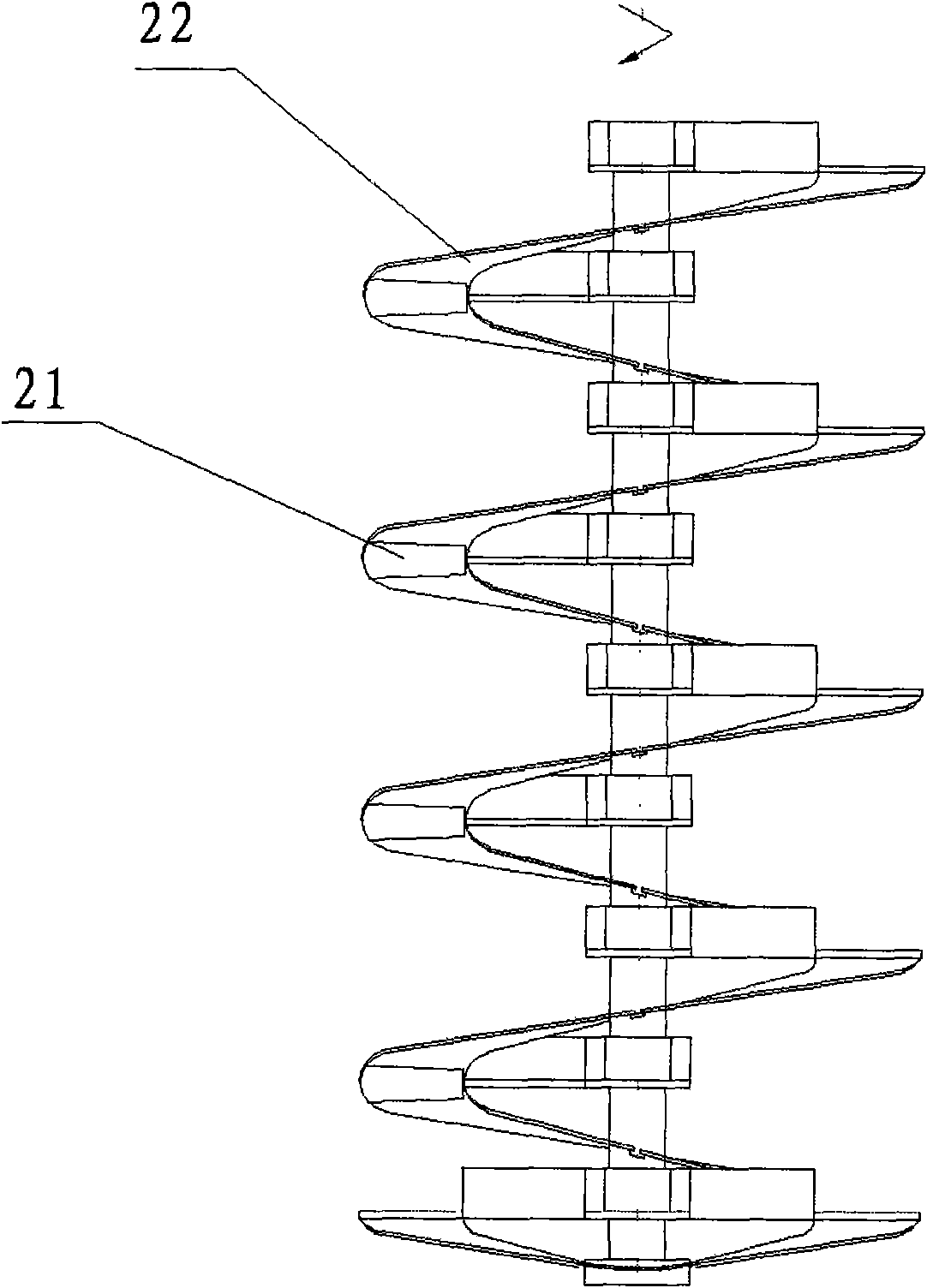

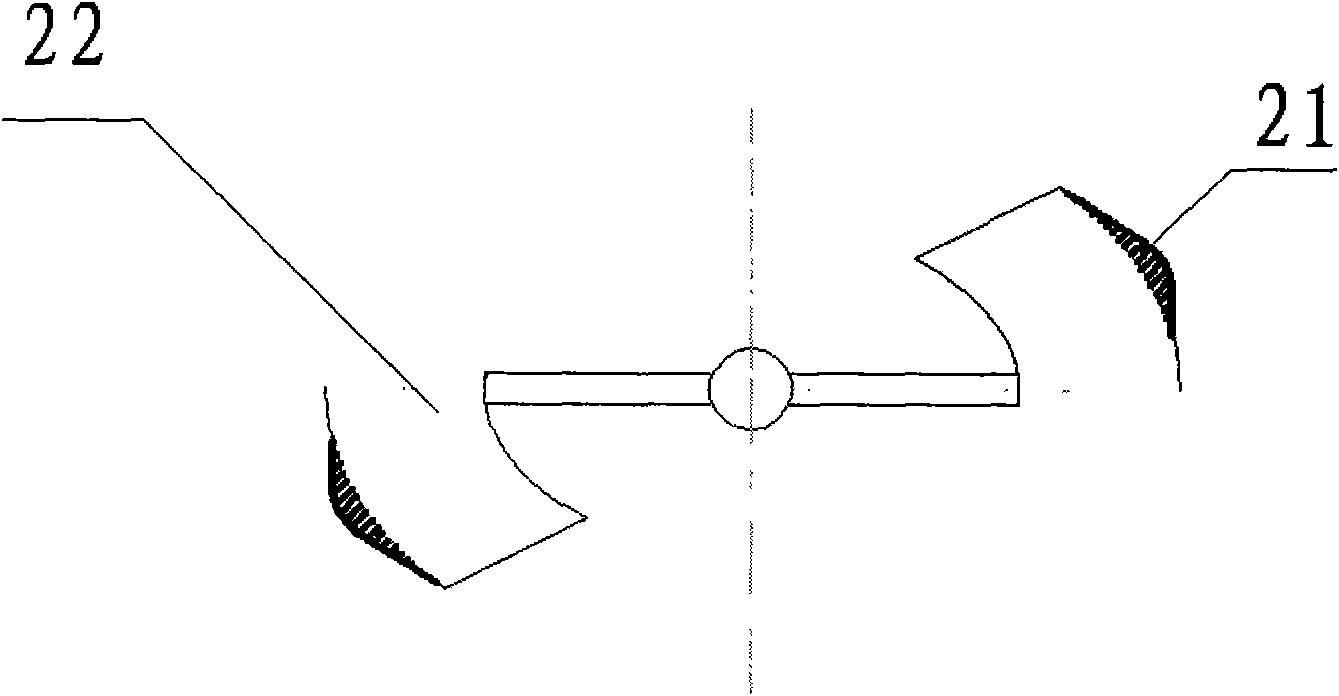

[0028] see figure 1 with Figure 4 , a polymerization kettle of the present invention, including a kettle body 10 and an agitator 20 installed in the kettle body 10; wherein, the volume of the kettle body 10 is 12m 3 ~70m 3 , and its aspect ratio is 2-3. In this implementation, the volume of kettle body 10 is 15m 3 , its aspect ratio is 2.1, and an external circulation condensation system 30 for removing heat from the polymerization kettle is installed outside the kettle body 10. The heat removal performance of the polymerization kettle 100 is improved through the external circulation condensation system, so that the advantages of high-efficiency catalyst and high activity are obtained. Fully exerted, the production capacity of the polymerizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com