High-efficiency energy-saving high-technology ceramic material synthesis pre-burning kiln

A ceramic material, high-efficiency and energy-saving technology, applied in furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of inability to control the airflow direction of the kiln body, the length of the pre-fired kiln body is short, and the ineffective space cannot be used. Ineffective heating space, avoiding uneven heating, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

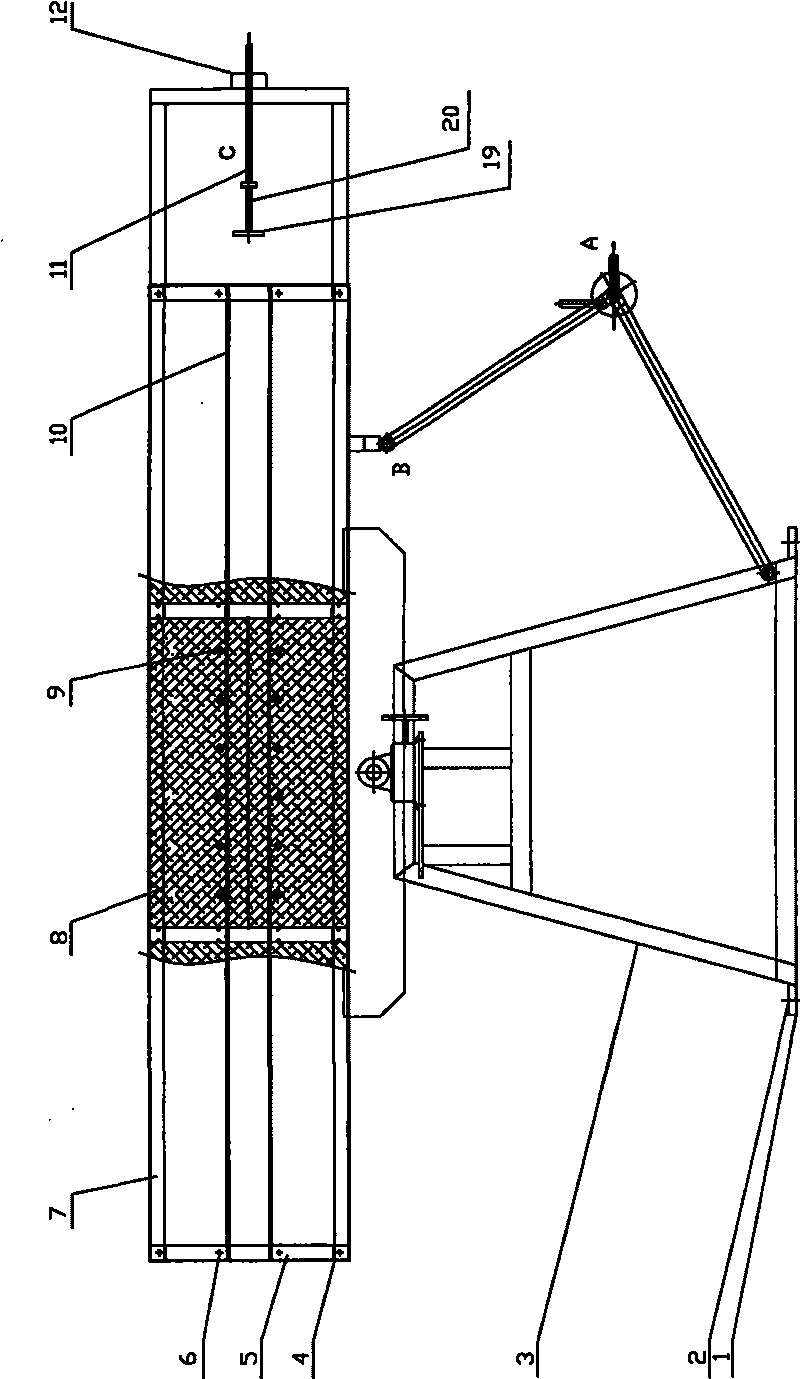

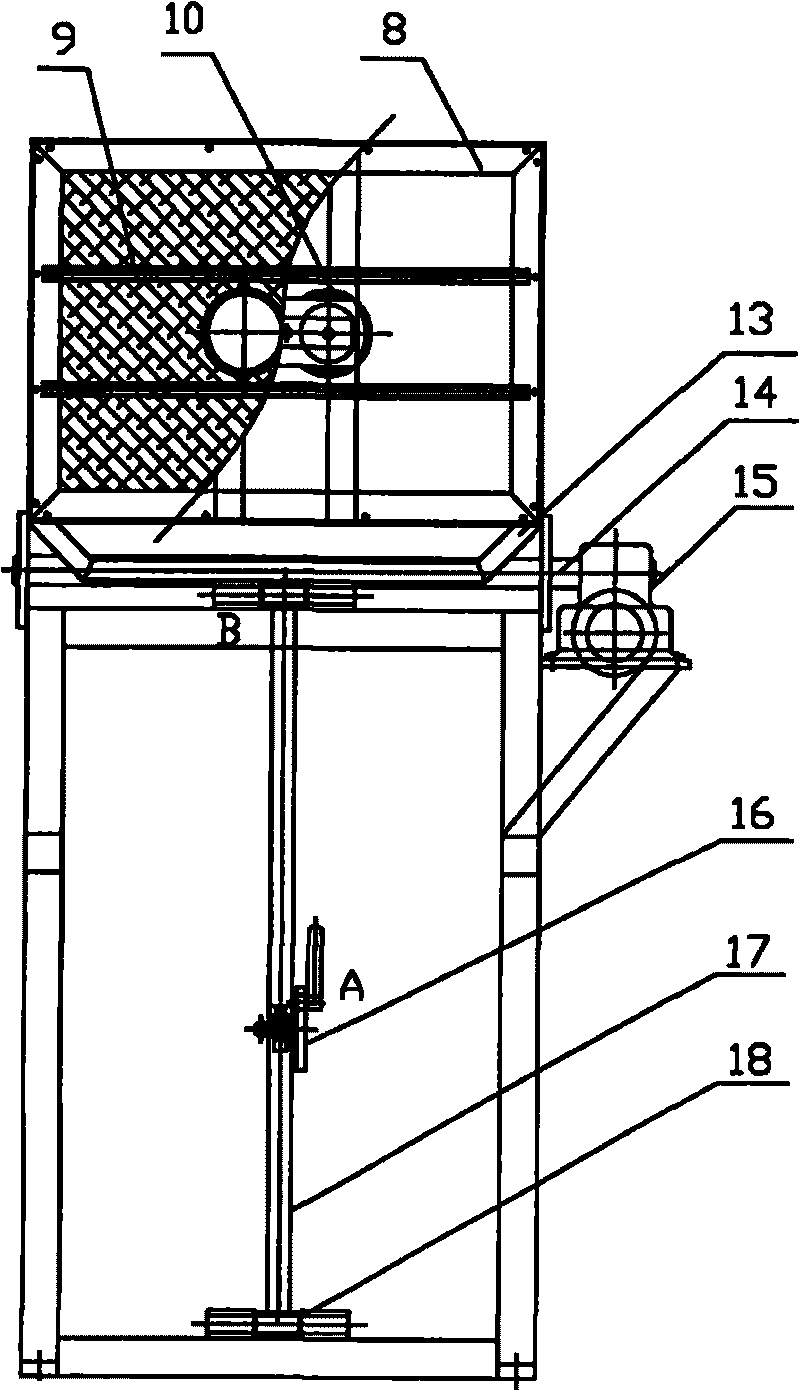

[0056] The high-efficiency energy-saving high-tech ceramic material synthesis pre-fired kiln of this embodiment is placed horizontally, and the powder material to be synthesized and pre-fired is pressed into a cylinder, which is sent into the refractory material pipe channel 10 by the push rod 20 of the propulsion device 11, and Under the action of the push rod 20, it is transported in the channel 10 of the refractory material pipe.

[0057] A high-efficiency energy-saving high-tech ceramic material synthesis pre-fired kiln, which is composed of a kiln body 8 of refractory material, a refractory material tube channel 10 placed in the kiln body 8, and an electric heating body 9. The refractory material tube channel 10 is two A refractory pipe body that runs through from end to end, and an electric heating body 9 is arranged in the middle section of the kiln body 8 .

[0058] The refractory tube channels 10 are arranged side by side. The cross-sectional shape of the refractory ...

Embodiment 2

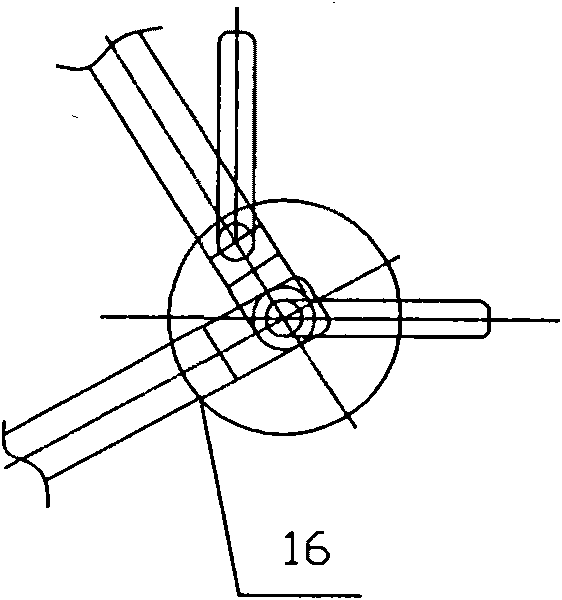

[0060] The inclination angle of the high-efficiency energy-saving high-tech ceramic material synthesis pre-fired kiln in this embodiment can be adjusted and controlled. The material is transported in the tube channel 10.

[0061] A high-efficiency energy-saving high-tech ceramic material synthesis pre-fired kiln, which is composed of a kiln body 8 of refractory material, a refractory material tube channel 10 placed in the kiln body 8, and an electric heating body 9. The refractory material tube channel 10 is four A refractory pipe body that runs through from end to end, and the electric heating body 9 is arranged in the middle section of the kiln body.

[0062] The inclination angle of the kiln body 8 is adjustable. The refractory tube channels 10 are arranged side by side. The cross-sectional shape of the refractory pipe channel 10 is square. The refractory pipe channel 10 is made of Dong Qingshi ceramics. The electric heating body 9 is a carbon rod. The carbon rods are ...

Embodiment 3

[0067] The inclination angle of the high-efficiency energy-saving high-tech ceramic material synthesis pre-fired kiln in this embodiment can be adjusted and controlled. The material is transported in the tube channel 10.

[0068] A high-efficiency energy-saving high-tech ceramic material synthesis pre-fired kiln, which is composed of a kiln body of refractory material, a refractory material tube channel 10 placed in the kiln body 8, and an electric heating body 9, and the refractory material tube channel 10 is four The end-to-end refractory pipe body, the electric heating body 9 is arranged in the middle section of the kiln body 8 .

[0069] The inclination angle of the kiln body 8 is adjustable. Two refractory material pipe passages 10 are stacked one above the other. The cross-sectional shape of the refractory pipe channel 10 is circular. The refractory tube channel 10 is made of alumina ceramics. The electric heating body 9 is an electric heating wire. The heating wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com