Method for making nitre and drying and drying apparatus thereof

A drying equipment and drying technology, applied in drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve the problems of high energy consumption, affecting the appearance of Yuanming powder products, and reducing the particle size of Yuanming powder. , to achieve the effect of low energy consumption, stable drying effect and small crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

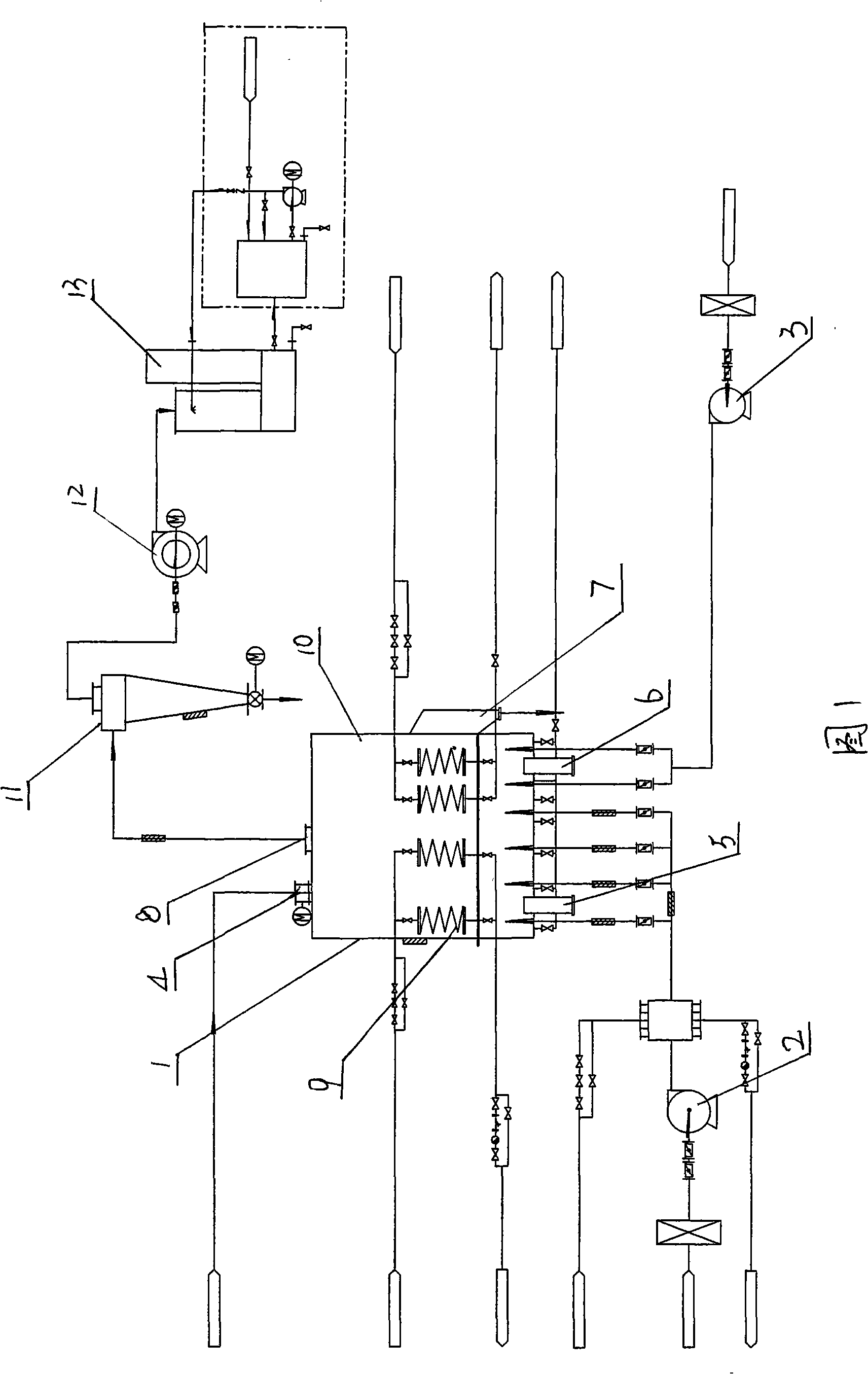

[0020] The drying equipment includes a fluidized bed dryer 1, a hot air blower 2 and an internal cooler 3. The fluidized bed dryer 1 is divided into a drying section and a cooling section. The section is provided with a cold air inlet 6, a material outlet 7 and an exhaust gas outlet 8, the hot air blower 2 is connected to the hot air inlet 5 through a pipeline, and the cold air blower 3 is connected to the cold air inlet 6 through a pipeline.

[0021] When drying, firstly, in the drying section, the wet nitric acid entering the fluidized bed dryer exchanges heat with the hot air entering the fluidized bed dryer, and secondly, the dried hot nitric acid enters the cooling section, and the hot nitric acid and the incoming cold air Heat exchange is carried out, and finally, the cooled cold nitric acid is discharged from the fluidized bed dryer.

[0022] In a method for drying nitric acid of the present invention, the moisture content of wet nitric acid is 2.0%, the temperature of ...

Embodiment 2

[0024] The drying equipment includes a fluidized bed dryer 1, a hot air blower 2 and an internal cooler 3. The fluidized bed dryer 1 is divided into a drying section and a cooling section. The section is provided with a cold air inlet 6, a material outlet 7 and an exhaust gas outlet 8, the hot air blower 2 is connected to the hot air inlet 5 through a pipeline, and the cold air blower 3 is connected to the cold air inlet 6 through a pipeline.

[0025] When drying, firstly, in the drying section, the wet nitric acid entering the fluidized bed dryer exchanges heat with the hot air entering the fluidized bed dryer, and secondly, the dried hot nitric acid enters the cooling section, and the hot nitric acid and the incoming cold air Heat exchange is carried out, and finally, the cooled cold nitric acid is discharged from the fluidized bed dryer.

[0026] In the drying method for producing nitric acid of the present invention, the moisture content of wet nitric acid is 3.0%, the tem...

Embodiment 3

[0028] The drying equipment includes a fluidized bed dryer 1, a hot air blower 2 and an internal cooler 3. The fluidized bed dryer 1 is divided into a drying section and a cooling section. The section is provided with a cold air inlet 6, a material outlet 7 and an exhaust gas outlet 8, the hot air blower 2 is connected to the hot air inlet 5 through a pipeline, and the cold air blower 3 is connected to the cold air inlet 6 through a pipeline.

[0029] When drying, firstly, in the drying section, the wet nitric acid entering the fluidized bed dryer exchanges heat with the hot air entering the fluidized bed dryer, and secondly, the dried hot nitric acid enters the cooling section, and the hot nitric acid and the incoming cold air Heat exchange is carried out, and finally, the cooled cold nitric acid is discharged from the fluidized bed dryer.

[0030] In a method for drying nitric acid of the present invention, the moisture content of wet nitric acid is 4.0%, the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com