Polyindole crosslinked polyvinylidene fluoride binder and lithium ion battery applying the same

A technology of polyvinylidene fluoride and lithium-ion batteries, which is applied in the manufacture of battery electrodes, non-aqueous electrolyte batteries, and electrolyte batteries. resistance, reduce capacity, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

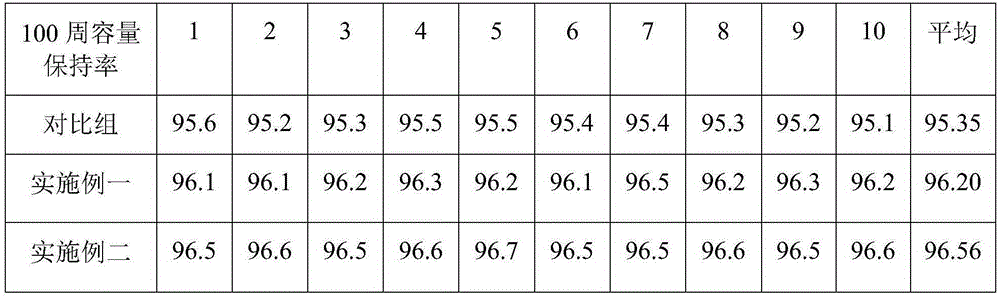

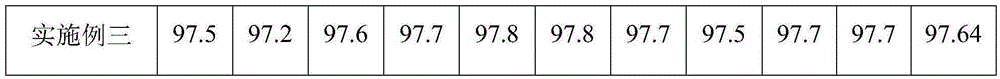

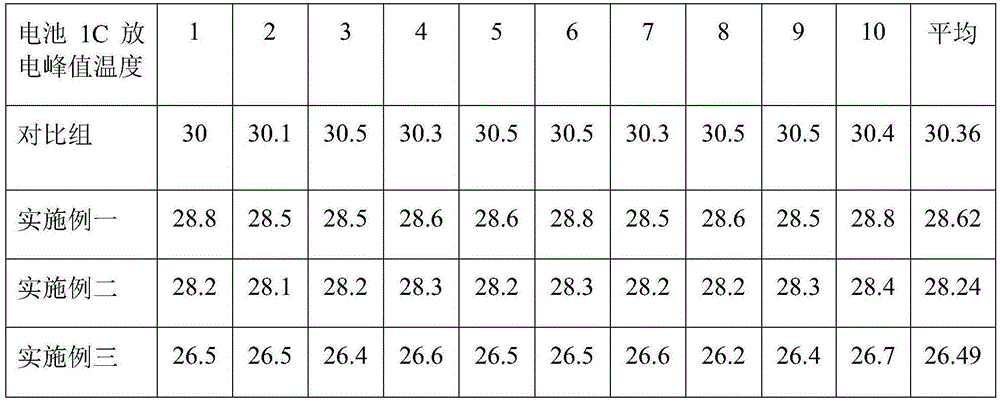

Examples

preparation example Construction

[0037] The preparation method of polyvinylidene fluoride binder comprises the steps:

[0038] (1) Pour 5kg of polyvinylidene fluoride into 95kg of N-methylpyrrolidone, and stir while adding. The adding time is 0.5h, and the overall stirring time is 4h. Use a double-star vacuum mixer with a revolution speed of 35-50rpm and a dispersion speed 800-1000rpm, maintain the temperature at 40-60°C, vacuum -0.1MPa after the stirring is completed, and maintain the pressure for 0.5h to obtain the mixed colloid B0.

[0039] The preparation method of the lithium-ion battery using above-mentioned binding agent, comprises the steps:

[0040] (1) Preparation of positive and negative electrode slurry:

[0041] Preparation of positive electrode slurry: Weigh 95.5kg ternary nickel-cobalt lithium manganate, 50kg mixed colloid B0, 1kgSuper-P and 1kgKS-6 graphite conductive agent, ternary nickel-cobalt lithium manganate: mixed colloid B0: Super-P: KS-6 graphite conductive agent = 95.5:50:1:1, firs...

Embodiment 1

[0047] A polybenzazole crosslinked polyvinylidene fluoride binder, the binder is crosslinked and polymerized by polybenzazole and polyvinylidene fluoride, and the mass ratio of polybenzazole to polyvinylidene fluoride is 2:8.

[0048] A preparation method of polybenzazole crosslinked polyvinylidene fluoride binder, comprising the steps of:

[0049] (1) Pre-mix 1 kg of polybenzazole and 4 kg of polyvinylidene fluoride with a three-dimensional mixer for 3-4 hours, and the mass ratio of polybenzazole to polyvinylidene fluoride is 2:8 to obtain mixed powder A1.

[0050] (2) After cooling 5kg of mixed powder A1 to room temperature (25°C), pour it into 57.5kg of N-methylpyrrolidone, and stir while adding. The addition time is 0.5h, and the overall stirring time is 4h. Use a double-star vacuum mixer, The revolution speed is 35-50rpm, the dispersion speed is 800-1000rpm, and the temperature is maintained at 40-60°C. After the stirring is completed, the vacuum is -0.1MPa, and the press...

Embodiment 2

[0062] A polybenzazole crosslinked polyvinylidene fluoride binder, the binder is crosslinked and polymerized by polybenzazole and polyvinylidene fluoride, and the mass ratio of polybenzazole to polyvinylidene fluoride is 5:5.

[0063] A preparation method of polybenzazole crosslinked polyvinylidene fluoride binder, comprising the steps of:

[0064] (1) Premix 2.5kg of polybenzazole and 2.5kg of polyvinylidene fluoride with a three-dimensional mixer for 3-4 hours, the mass ratio of polybenzazole to polyvinylidene fluoride is 4:6, and obtain mixed powder A2.

[0065] (2) After cooling 5kg of mixed powder A2 to room temperature (25°C), pour it into 57.5kg of N-methylpyrrolidone, and stir while adding. The addition time is 0.5h, and the overall stirring time is 4h. Use a double-star vacuum mixer, The revolution speed is 35-50rpm, the dispersion speed is 800-1000rpm, and the temperature is maintained at 40-60°C. After the stirring is completed, the vacuum is -0.1MPa, and the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com