Array needle-board type liquid phase plasma jetting generation apparatus

A liquid-phase plasma and generating device technology, applied in the direction of plasma, electrical components, etc., can solve the problems of inability to meet research needs, low plasma density, complex discharge forms, etc. Easy to install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

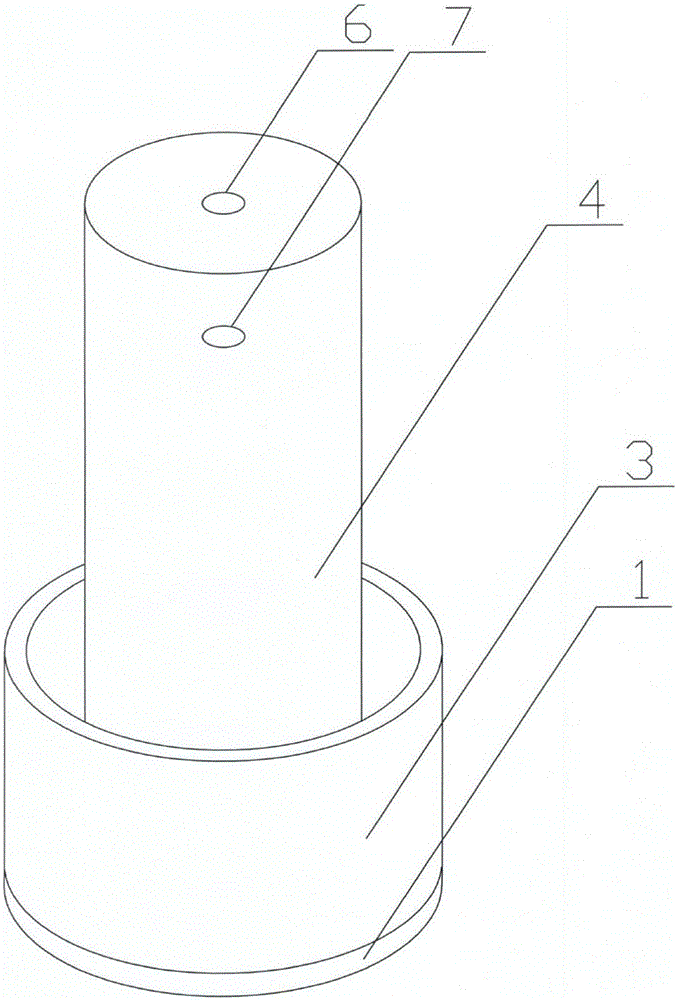

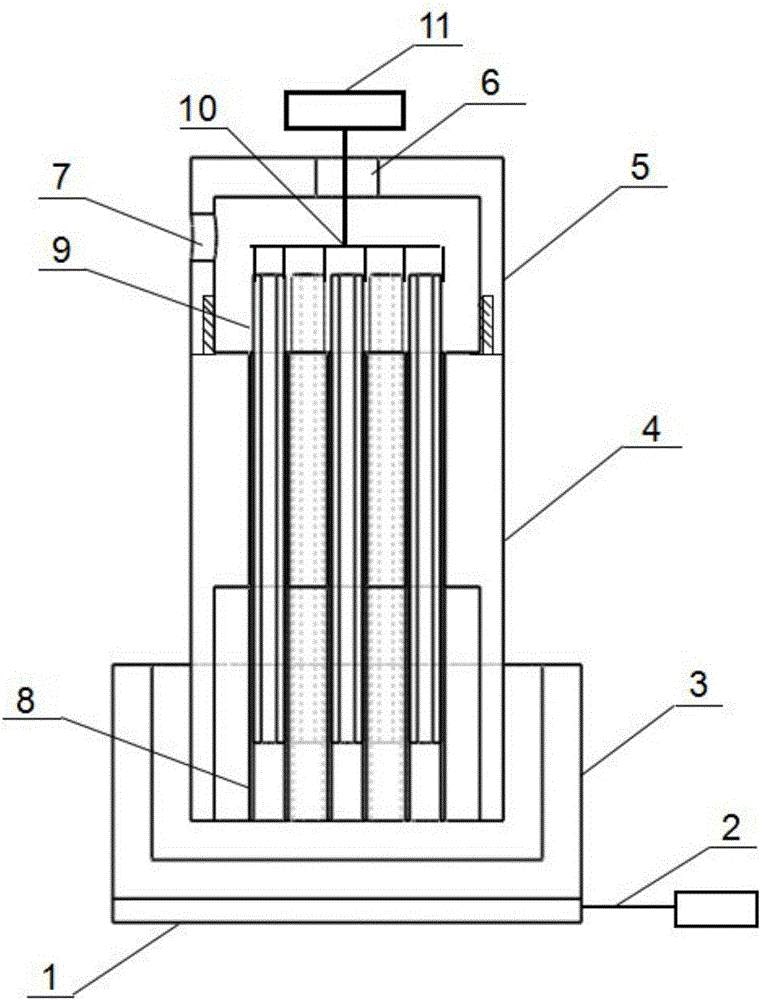

[0023] exist figure 1 and figure 2 In the schematic diagram of the present invention shown, the metal plate 1 is a circular flat plate, and the metal plate is grounded through a wire 2 . The metal plate is placed on the lower part of the medium body 3 . The diameter of the metal plate is the same as that of the lower surface of the medium body, and the medium body is a cylindrical shell with an upper opening. A ventilation mechanism is inserted inside the medium body. The lower end of the ventilation mechanism is higher than the lower end of the medium body. The ventilation mechanism is composed of a ventilation main body 4 and a ventilation top cover 5, and the ventilation main body and the ventilation top cover are connected by threads. An outlet 6 is provided at the center of the ventilation top cover. The ventilation main body is a cylinder, and a cylindrical groove is provided on the upper and lower parts of the ventilation main body, and a ventilation hole 7 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com