Cushioning internal rotation equipressure urea granulating injector

A technology of urea granulation and internal rotation, which is applied in the direction of liquid separation into beads and granulation, which can solve problems such as uneven liquid surface, achieve the effects of solving liquid surface pressure imbalance, reducing dust and hollow, and reducing discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

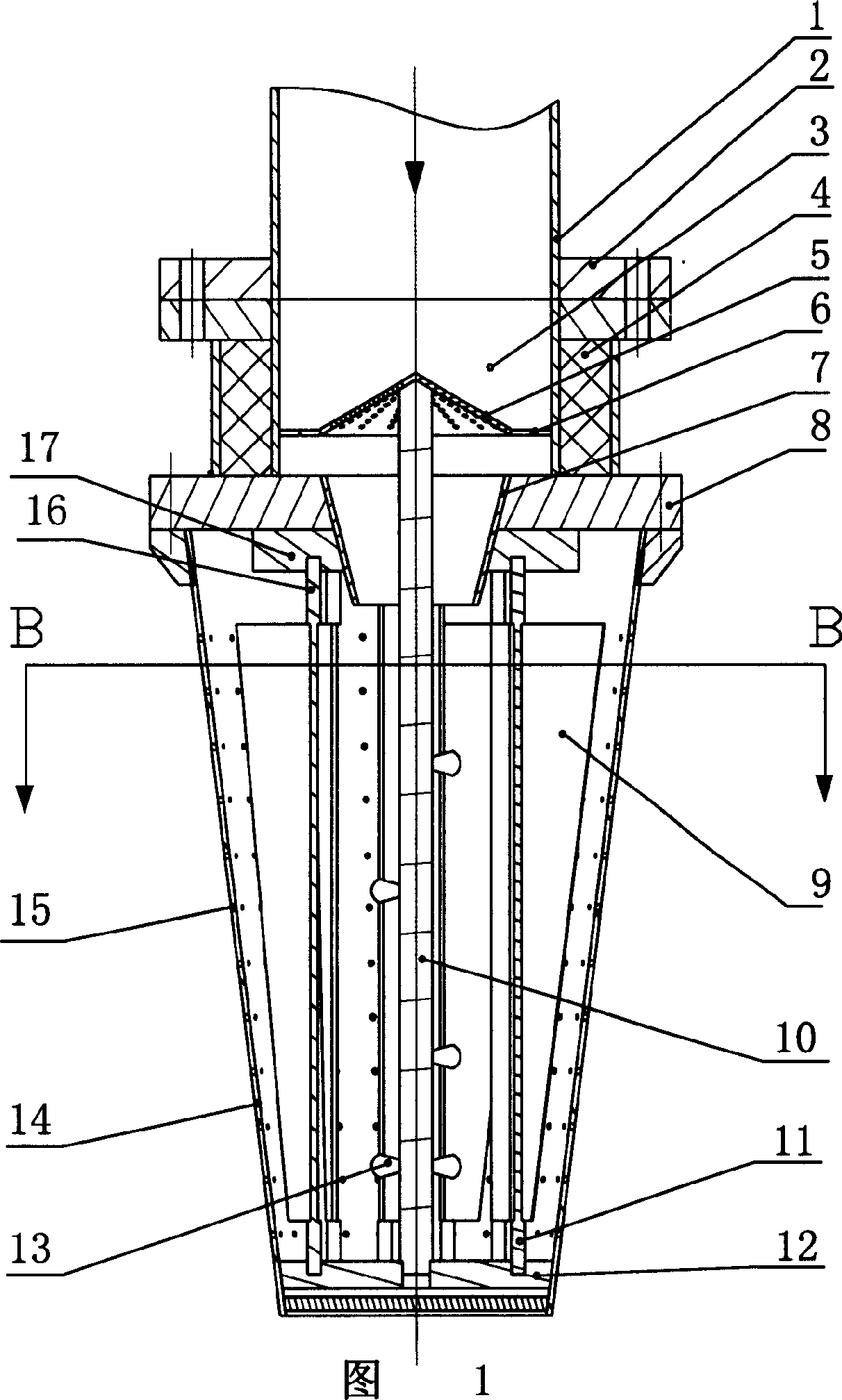

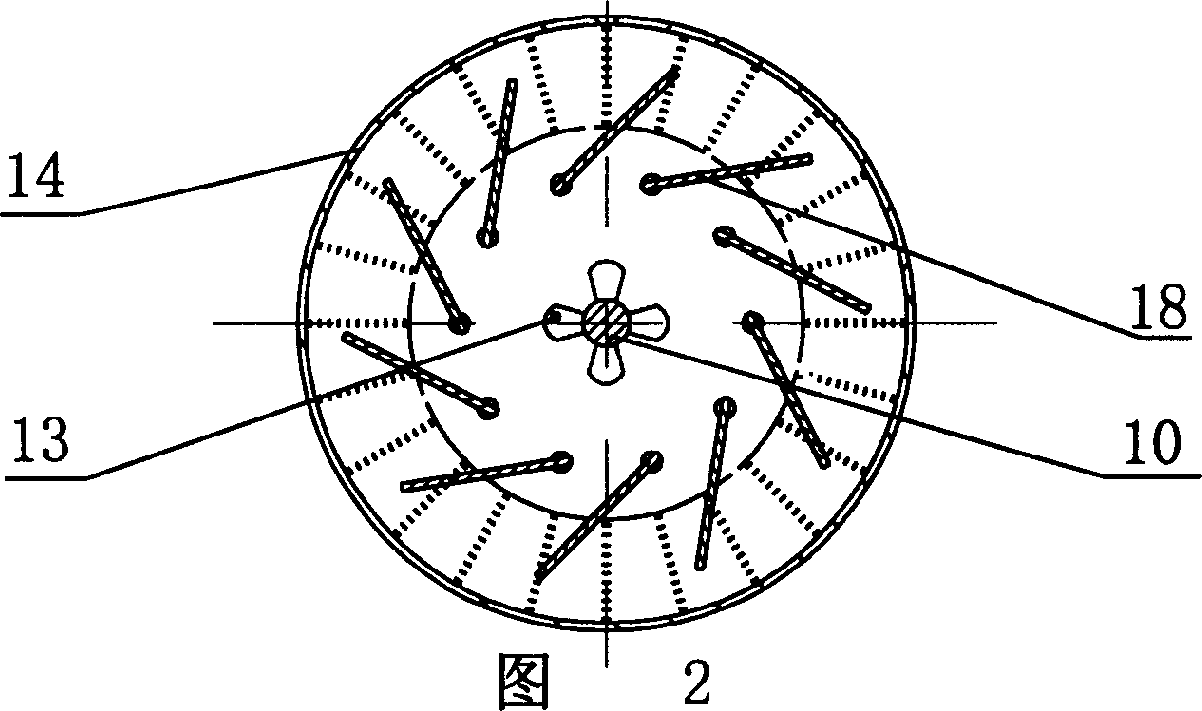

[0018] As shown in Figure 1, a buffer inner rotating isobaric urea granulation nozzle is installed on the granulator transmission hollow shaft 1 at the top of the granulation tower, and the nozzle body 14 is connected with the granulator transmission hollow shaft 1 by connecting the flange 2 , the buffer chamber 3, the thermal insulation interlayer 4 outside the buffer chamber 3, and the connecting plate 8 are integral components, and the buffer chamber 3 is provided with a buffer body 5; The distributor 9 is installed on the lower part of the nozzle body 14, the guide rod is installed in the center of the nozzle body 14, the upper end is fixed with the buffer body 5 through the flow nozzle 7, and the lower end is fixed on the lower positioning plate 12 of the nozzle body 14, and the nozzle body 14 is connected with The plate 8 is fixed coaxially, and the nozzle body 14 is provided with nozzle holes 15 . The guide rod 10 is a cylinder or a hollow cylinder, and the surface can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com