Processing technology of aluminum alloy profile and aluminum alloy profile

A technology of aluminum alloy profiles and processing technology, applied in the directions of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problem that the comprehensive mechanical properties and electrical conductivity of aluminum alloy profiles cannot meet the higher requirements of users at the same time, and achieve the microscopic gap of the profiles. Reduction, comprehensive mechanical properties guarantee, the effect of reducing the size of micro-gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A process for processing aluminum alloy profiles, comprising the following steps:

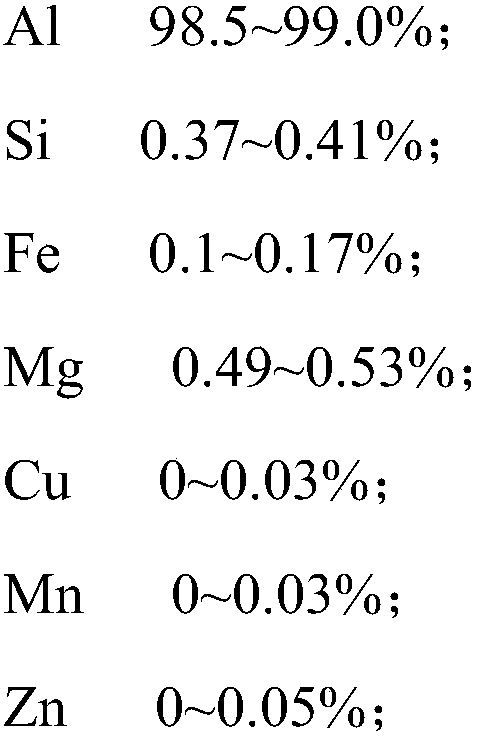

[0053] (1) The composition of the aluminum alloy ingot is detected, and the mass percentage of the components of the aluminum alloy ingot is obtained as follows:

[0054]

[0055] and other unavoidable impurities;

[0056] (2) Heat the aluminum alloy ingot to 490°C in an induction furnace, heat the mold to 440°C in a mold heating furnace, and heat the extrusion cylinder with the electromagnetic induction heater of the extruder, so that The temperature of the cylinder is 415°C;

[0057] (3) Place the aluminum alloy ingot heated in step (2) in the heated extrusion barrel, start the extruder to extrude, the extrusion temperature is 530°C, the extrusion speed is 12m / min, and the extrusion obtaining a first extruded profile;

[0058] (4) Use a tractor to pull the first extruded profile at the exit of the extrusion die hole, and use a water mist quenching device to perform online quenchi...

Embodiment 2~16

[0063] Table 1 Processing parameters of aluminum alloy profiles in Examples 2 to 16 of the present invention

[0064]

[0065]

[0066] Table 2 Performance test results of the aluminum alloy profiles of Examples 1 to 16 of the present invention

[0067]

[0068]

[0069] It can be seen from Tables 1 and 2 that the processing conditions of Examples 1 to 11 are the processing conditions for aluminum profiles provided by the present invention, and the obtained aluminum alloy profiles all meet the requirements in terms of comprehensive mechanical properties, and the electrical conductivity exceeds 56%. Although the comprehensive mechanical properties of 12-14 meet the requirements, the electrical conductivity is lower than 55%, while the Vickers hardness of Example 15 is relatively low, and the electrical conductivity of Example 16 is only 55.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com