Preparation method of hydrophobic oleophobic BC superfine dry powder extinguishing agent base material carbonate

A hydrophobic and oleophobic, ultra-fine dry powder technology, which is used in the preparation of alkali metal carbonate shapes, fire protection equipment, etc. The effect of strong adhesion and excellent hydrophobic and oleophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

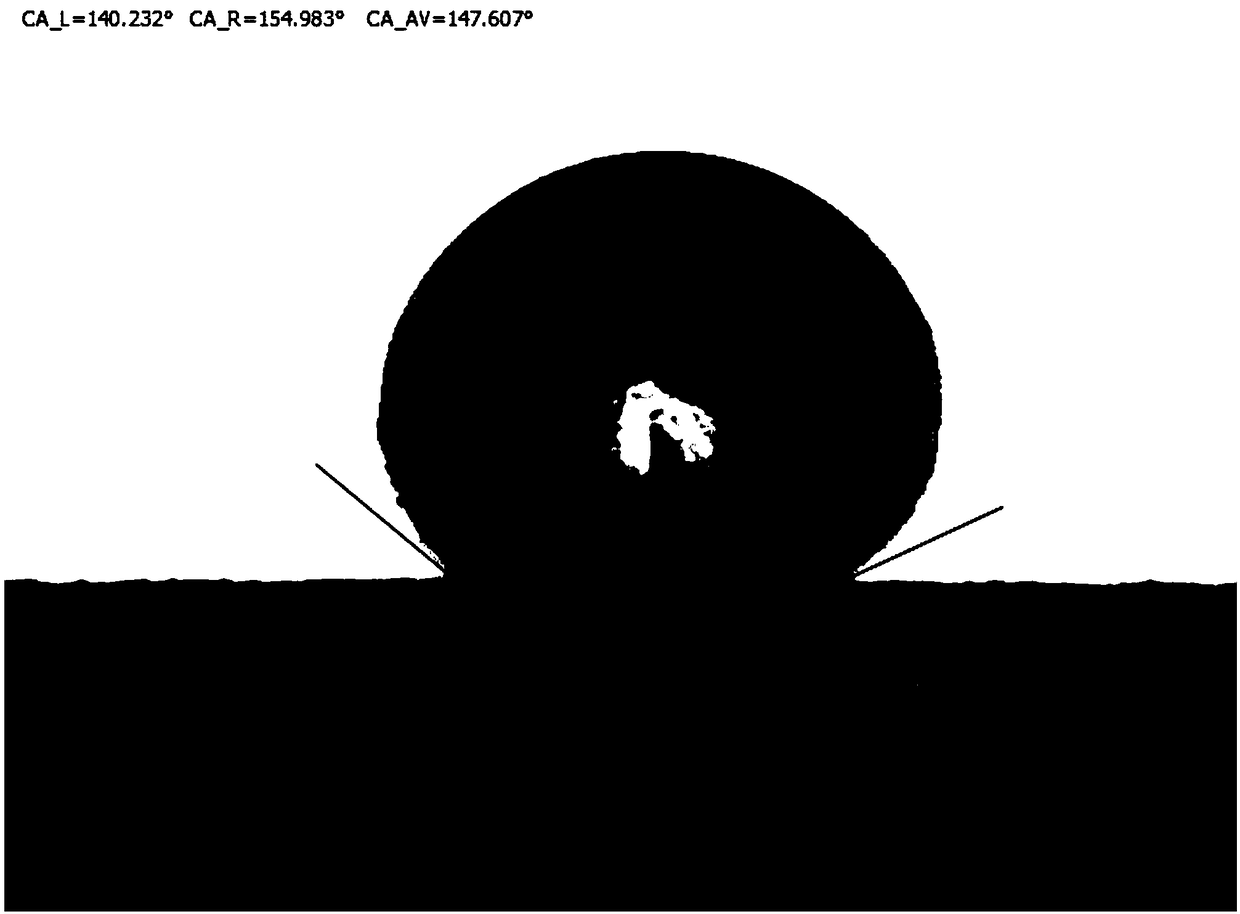

[0030] Embodiment 1: the preparation of hydrophobic and oleophobic superfine sodium bicarbonate powder

[0031] (1) Use a supersonic jet mill to crush sodium bicarbonate into an ultrafine powder with a particle size of 90% ≤ 5 μm;

[0032] (2) Add the ultrafine powder to the methanol solution of γ-aminopropyltriethoxysilane (KH550) at room temperature for impregnation treatment, stir at 1000rpm for 1h, and the weight percentage of each substance is the ultrafine powder The amount of methanol is 10%, the amount of methanol is 89%, and the amount of KH550 is 1%;

[0033] (3) Suction filter after the reaction, wash, dry at 100°C, cool, pulverize, and pass through a 400-mesh standard sampling sieve;

[0034] (4) Add the treated ultrafine powder into the acetone solution of tridecafluorooctyltriethoxysilane for impregnation treatment, stir at 1000rpm for 10h, and the weight percentage of each substance is the amount of ultrafine powder The amount of acetone is 10%, the amount of ...

Embodiment 2

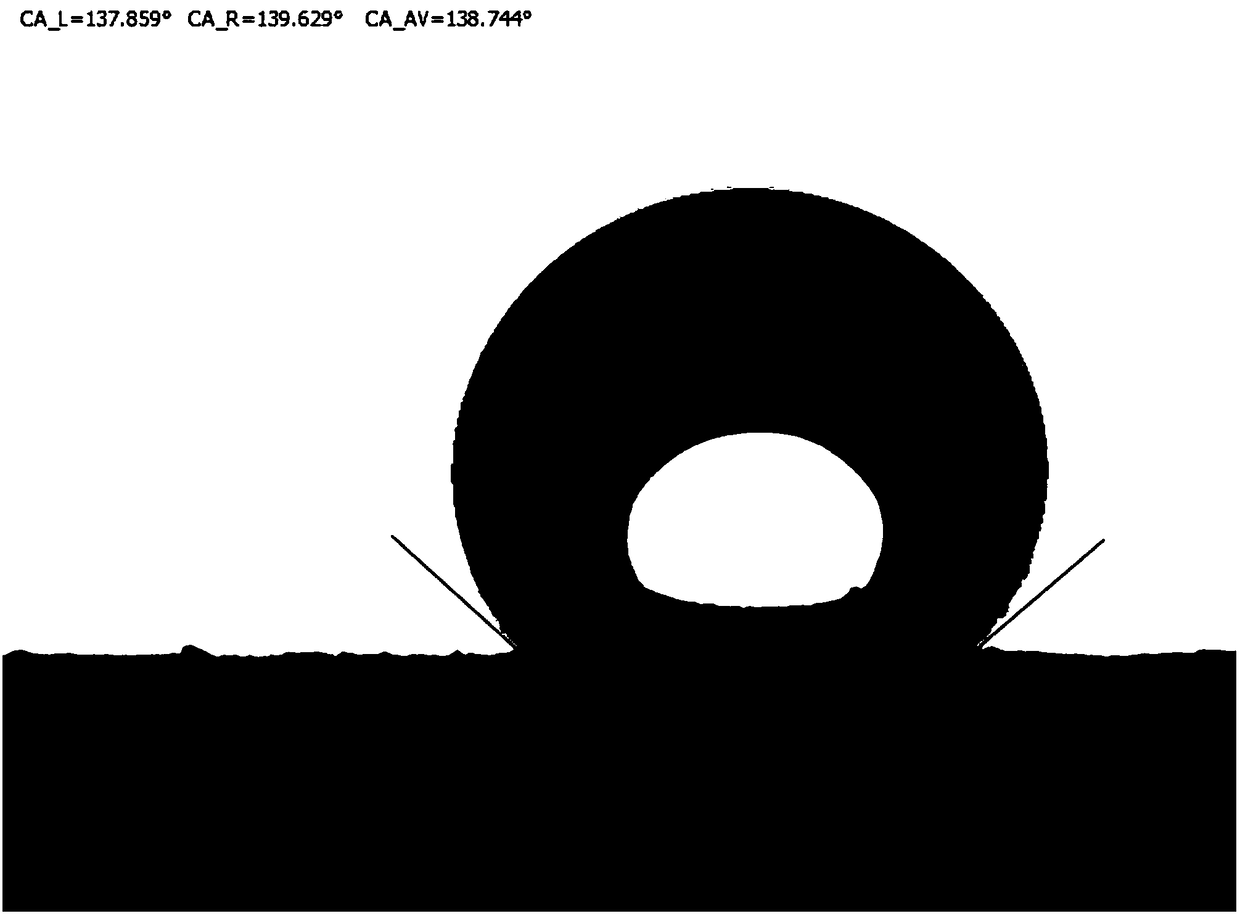

[0040] Embodiment 2: the preparation of hydrophobic and oleophobic superfine potassium bicarbonate powder

[0041] (1) Use a supersonic jet mill to crush potassium bicarbonate into ultrafine powder with 90% particle size ≤ 5 μm;

[0042] (2) Add the ultrafine powder into the acetone solution of γ-glycidyl etheroxypropyltrimethoxysilane (KH560) at room temperature for impregnation treatment, stir at 1000rpm for 2h, and the weight percentage of each substance is ultrafine The amount of powder is 10%, the amount of acetone is 67%, and the amount of KH560 is 3%;

[0043] (3) After the reaction, filter with suction, wash, dry at 110°C, cool, pulverize, and pass through a 400-mesh standard sampling sieve;

[0044] (4) Add the treated ultrafine powder into the n-hexane solution of heptadecafluorodecyltrimethoxysilane for impregnation treatment, stir at 1000rpm for 12h, and the weight percentage of each substance is the amount of ultrafine powder The amount of n-hexane is 5%, the am...

Embodiment 3

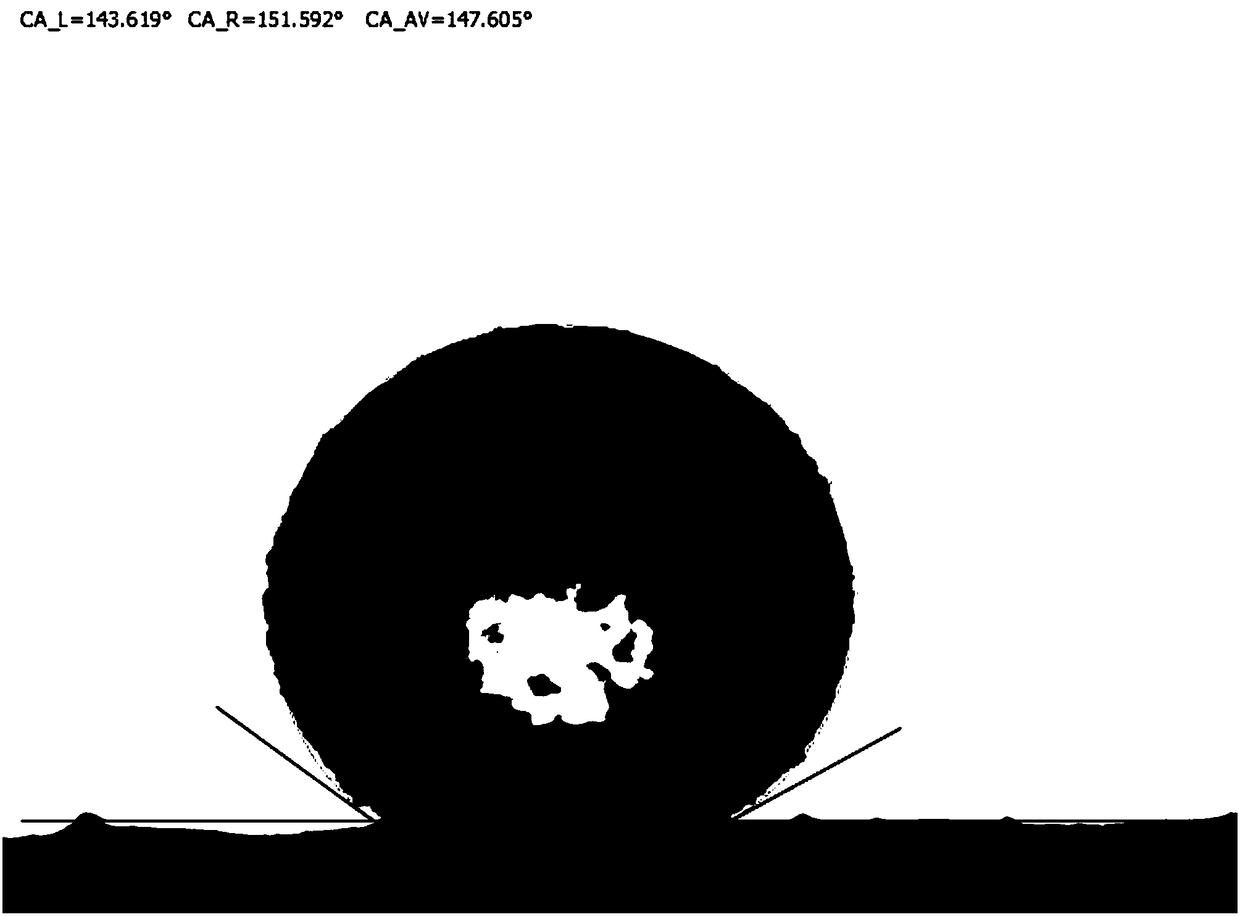

[0050] Embodiment 3: the preparation of hydrophobic and oleophobic superfine sodium bicarbonate powder

[0051] (1) Use a supersonic jet mill to crush sodium bicarbonate into an ultrafine powder with a particle size of 90% ≤ 5 μm;

[0052] (2) Add the ultrafine powder into the n-hexane solution of γ-aminopropyltriethoxysilane (KH550) at room temperature for impregnation treatment, stir at 1000rpm for 2h, and the weight percentage of each substance is ultrafine powder The amount of solid is 30%, the amount of n-hexane is 67%, and the amount of KH550 is 3%.

[0053] (3) After the reaction, filter with suction, wash, dry at 115°C, cool, pulverize, and pass through a 400-mesh standard sampling sieve;

[0054] (4) Add the treated ultrafine powder to the ethanol solution of perfluorodecyltriethoxysilane for impregnation treatment, stir at 1000rpm for 12h, and the weight percentage of each substance is the amount of ultrafine powder: 1%, the amount of ethanol is 98.9%, and the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com