Spherical fertilizers and process for the production thereof

A fertilizer, spherical technology, applied in the field of spherical fertilizer and its production, can solve the problems of high incidence of shutdown, increased porosity of finished products, and low bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

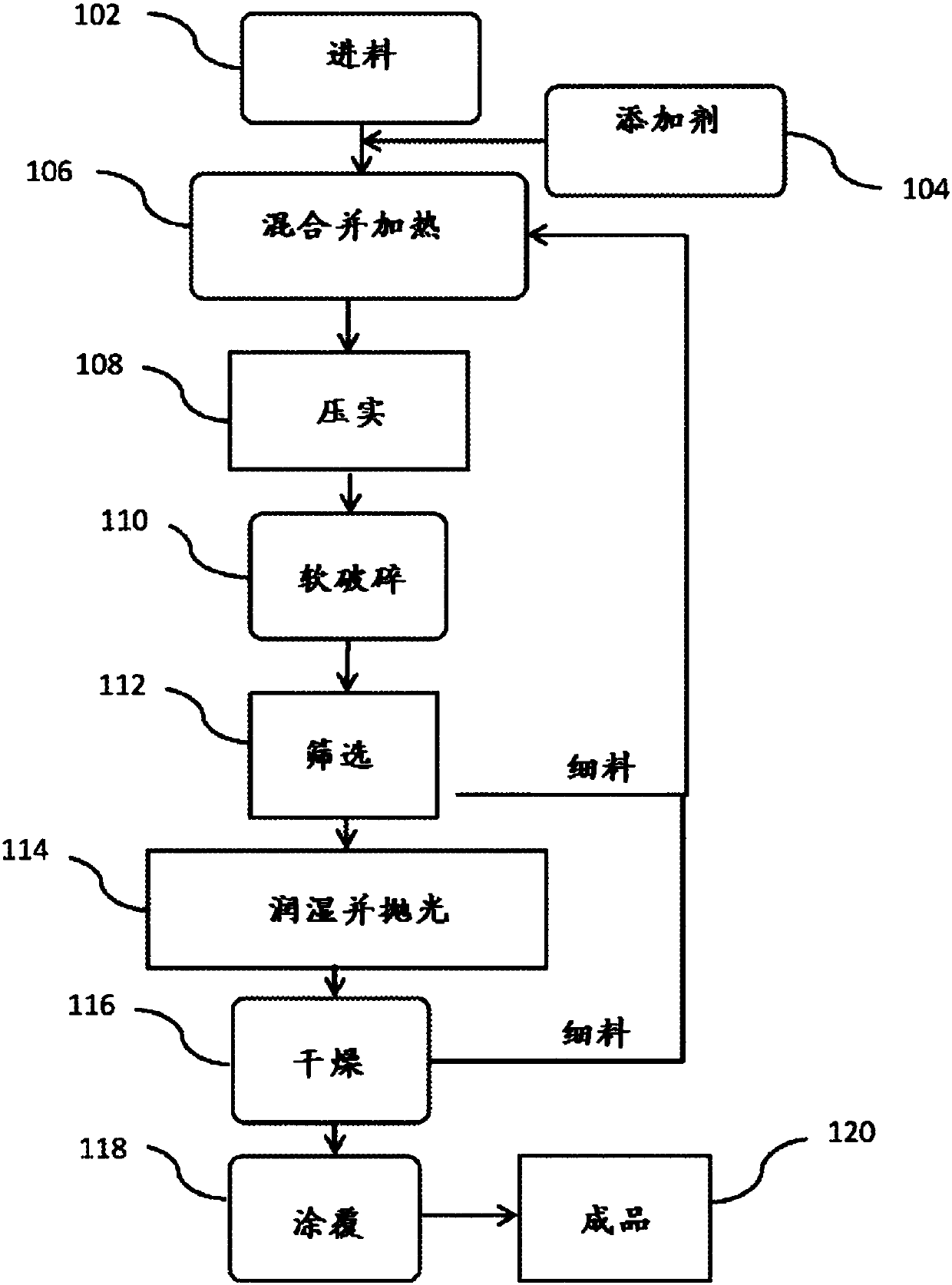

Method used

Image

Examples

Embodiment approach

[0066] According to some demonstrative embodiments, the one or more binders may include any suitable material or compound that can mechanically and / or chemically hold or attract other materials together to form a bonded whole, including, for example, organic or inorganic binders such as starch, bentonite, sodium silicate, lignosulfonate, molasses, hydrated lime, bitumen, Portland cement, clay, acids (nitric acid, hydrochloric acid, phosphoric acid, sulfuric acid), cellulose gum, Sucrose, water, water glass, cement or combinations thereof.

[0067] According to some embodiments, the method's manipulation of various characteristics can provide various characteristics that characterize the finished product, such as a unique sustained release profile.

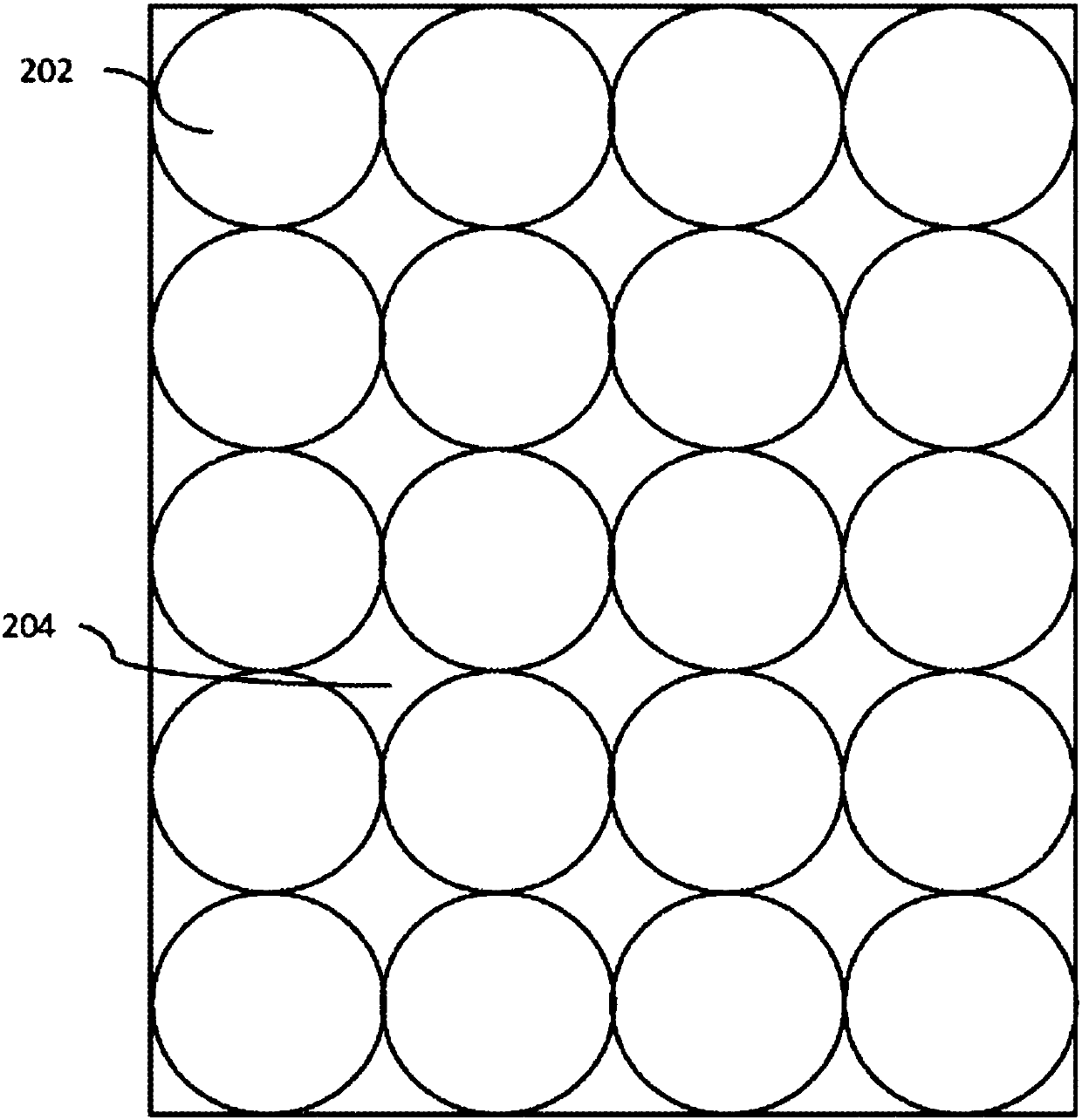

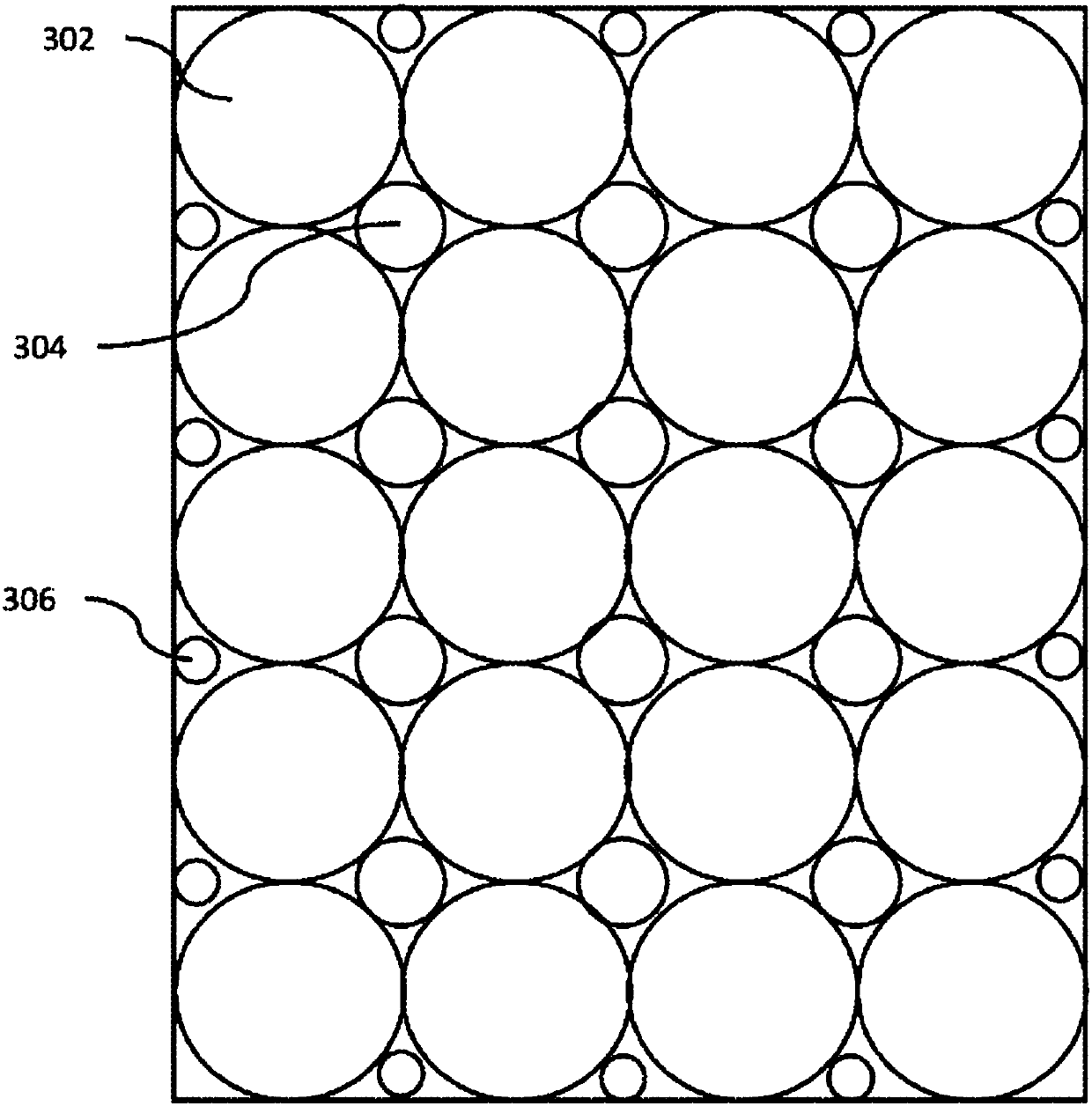

[0068] According to some demonstrative embodiments, the methods of the present invention may enable the production of spherical fertilizers of various shapes to obtain finished products having particles of different sizes. Accordi...

Embodiment 1

[0116] equipment:

[0117] Compactor Sahut Conrehur 250 / 40.

[0118] Tire type: pocket, pocket diameter 3 to 6mm.

[0119] Mixer Hi share 200L

[0120] Filter Boltom

[0121] Coating roller with spray system

[0122] fluid bed dryer

[0123] Feed:

[0124] Potash dust.

[0125] Particle size: less than 200 microns.

[0126] KCl content: 97%

[0127] Moisture<0.1%

[0128] No anti-caking additives

[0129] describe:

[0130] The material was fed at room temperature (20°C) to 160°C.

[0131] The compactor was operated under special conditions to produce balls of 3, 4 and 5 mm diameter with a specific gravity of 1.90-1.99 gr / cm3.

[0132] The force feeder, tire speed, and gap between tires were varied to produce pellets with minimal thickness connections between them.

[0133] Remove the force feeder and feed the material directly into the compactor (gravity), install a small disc to reduce flow.

[0134] The initial gap between the rolls was 0.3 mm. Synchronize th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com