Preparation method of large-particle heavy baking soda

A large particle and baking soda technology, which is applied in bicarbonate preparation, alkali metal carbonate shape preparation, etc., can solve the problem of difficult control of supersaturation, and achieve the effect of increased output, simple process, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

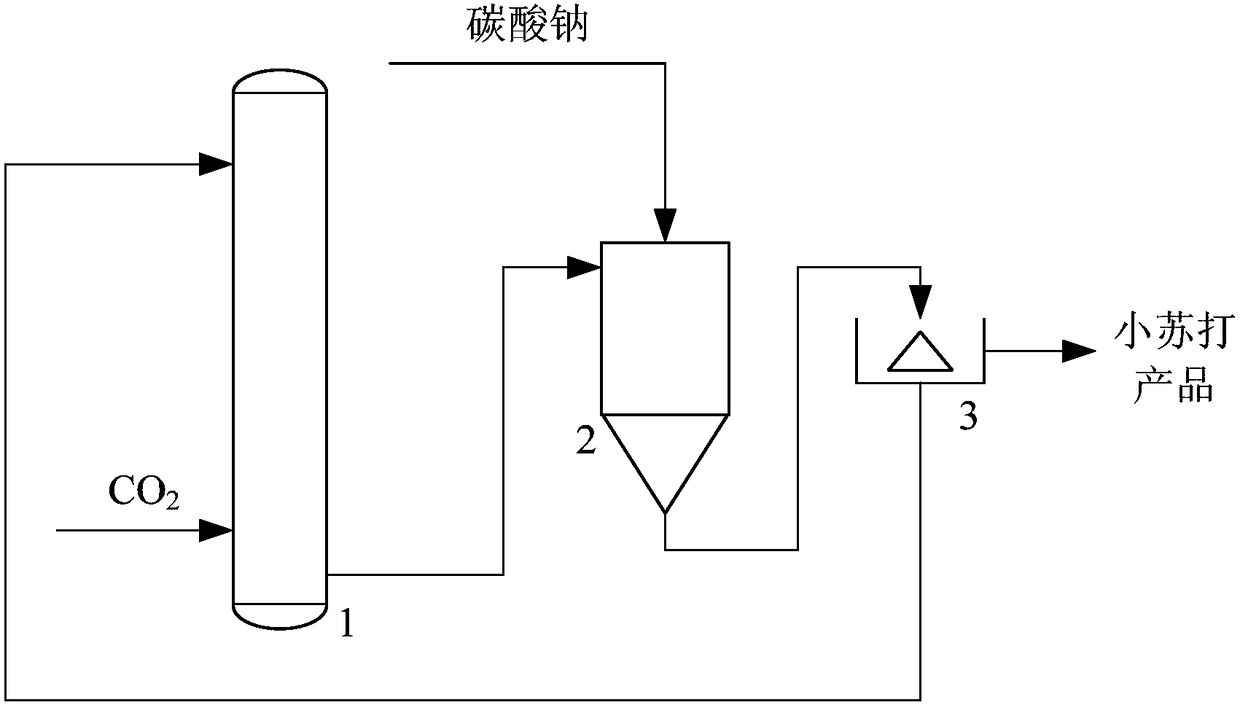

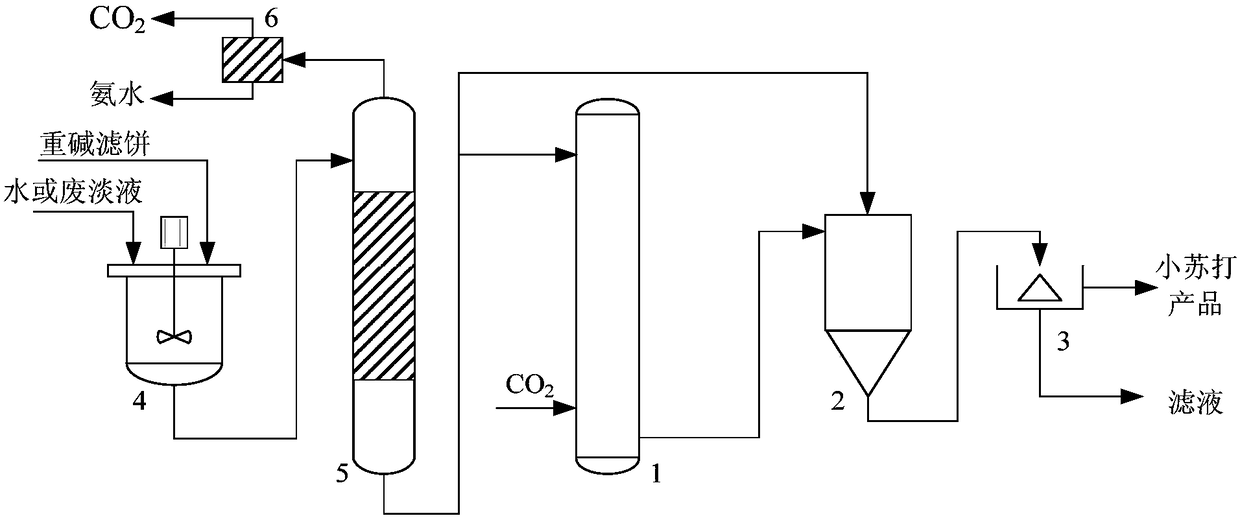

[0043] A preparation method of large particle heavy baking soda, said method may further comprise the steps:

[0044] (1) Sodium carbonate solution and CO 2 Carry out carbonation reaction, obtain by 204g NaHCO 3 Solid and 1000ml solution (containing Na 2 CO 3 42g / L, NaHCO 3 146g / L) composition;

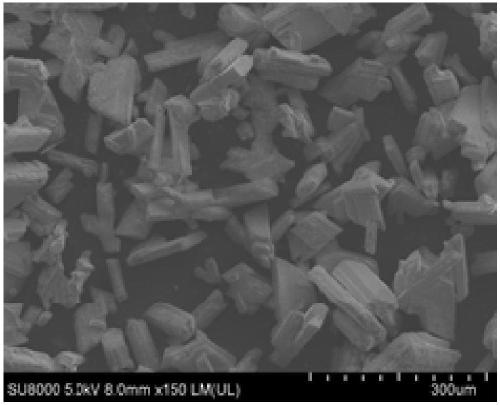

[0045] (2) The mixed material that step (1) is obtained joins in the reactor, adds 100g sodium carbonate wherein, crystallizes (insulation 2 hours) under 35 ℃, filters, and obtains large particle heavy baking soda.

Embodiment 2

[0047] A preparation method of large particle heavy baking soda, said method may further comprise the steps:

[0048] (1) Sodium carbonate solution and CO 2 Carry out carbonation reaction, obtain by 220g NaHCO 3 Solid and 1000ml solution (containing Na 2 CO 3 36g / L, NaHCO 3 122g / L);

[0049] (2) Add the mixture obtained in step (1) into a crystallizer, add 12.2g of sodium carbonate and 20ppmDL-tartaric acid therein, crystallize at 10°C (insulated for 3 hours), and filter to obtain large particles of heavy baking soda.

Embodiment 3

[0051] A preparation method of large particle heavy baking soda, said method may further comprise the steps:

[0052] (1) Sodium carbonate solution and CO 2 Carry out carbonation reaction, obtain by 214g NaHCO 3 Solid and 1000ml solution (containing Na 2 CO 3 45g / L, NaHCO 3 153g / L) composition;

[0053] (2) The mixture that step (1) obtains is joined in the crystallizer, adds 120g sodium carbonate and 500ppm calcium chloride wherein, crystallization (insulated 3 hours) under 80 ℃, filters, and obtains large particle heavy baking soda.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com