Carbonization crystallization technology in process for producing sodium carbonate through Hou's method

A technology of production process and combined alkali method, which is applied in the direction of alkali metal carbonate shape preparation, etc., to achieve the effects of prolonging residence time, increasing conversion rate, and increasing carbonization conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

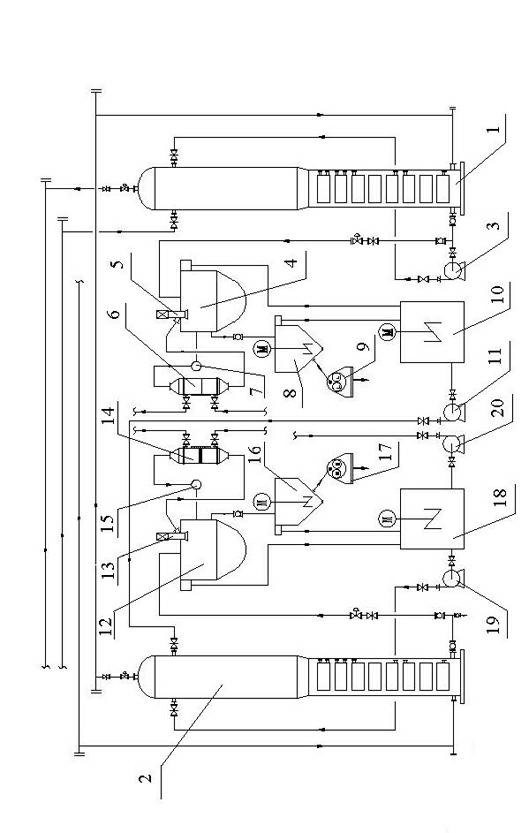

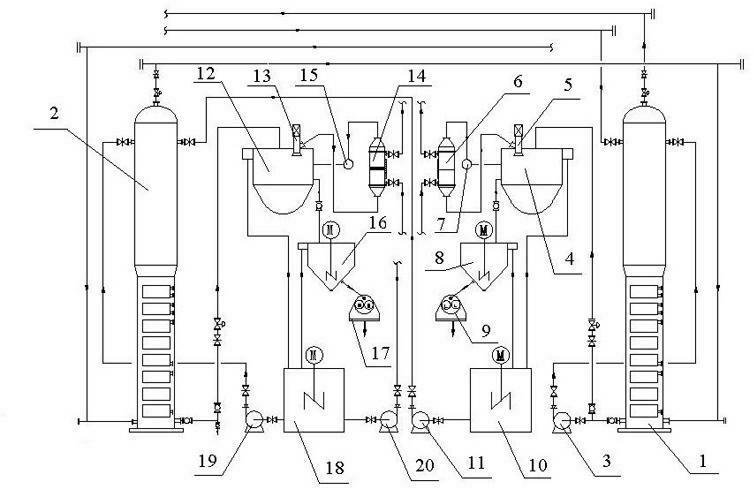

[0016] Embodiment 1, with reference to figure 1 , a carbonization crystallization process in the soda ash production process of a combined alkali method, its steps are as follows:

[0017] (1) The ammonia II mother liquor is sent to the carbonization cleaning tower 1, and the cleaning gas output from the soda making tower 2 is countercurrently contacted and reacted for pre-carbonization to obtain a pre-carbonized liquid; the exhaust gas discharged from the carbonization cleaning tower 1 is output to the tail gas purification tower; carbonization The cleaning tower 1 is connected to the cleaning pump 3 and the pre-carbonization liquid is used to clean the carbonization cleaning tower 1 in a cycle;

[0018] (2) Send the pre-carbonized liquid taken out from the bottom of the carbonization cleaning tower 1 to the primary crystallizer 4, then send it to the primary cooler 6 through the first axial flow pump 5 to exchange heat with cooling water for cooling, and return to the primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com