Evaporative-crystallization salt making equipment and wastewater treatment system for treating high-salt organic wastewater

A technology of evaporative crystallization and equipment, which is applied in the field of evaporative crystallization salt production equipment and wastewater treatment systems, can solve the problems of low treatment efficiency, complex structure, and no specific structure of saturated brine scrubber disclosed, and achieve high treatment efficiency and simplified equipment structure , Improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

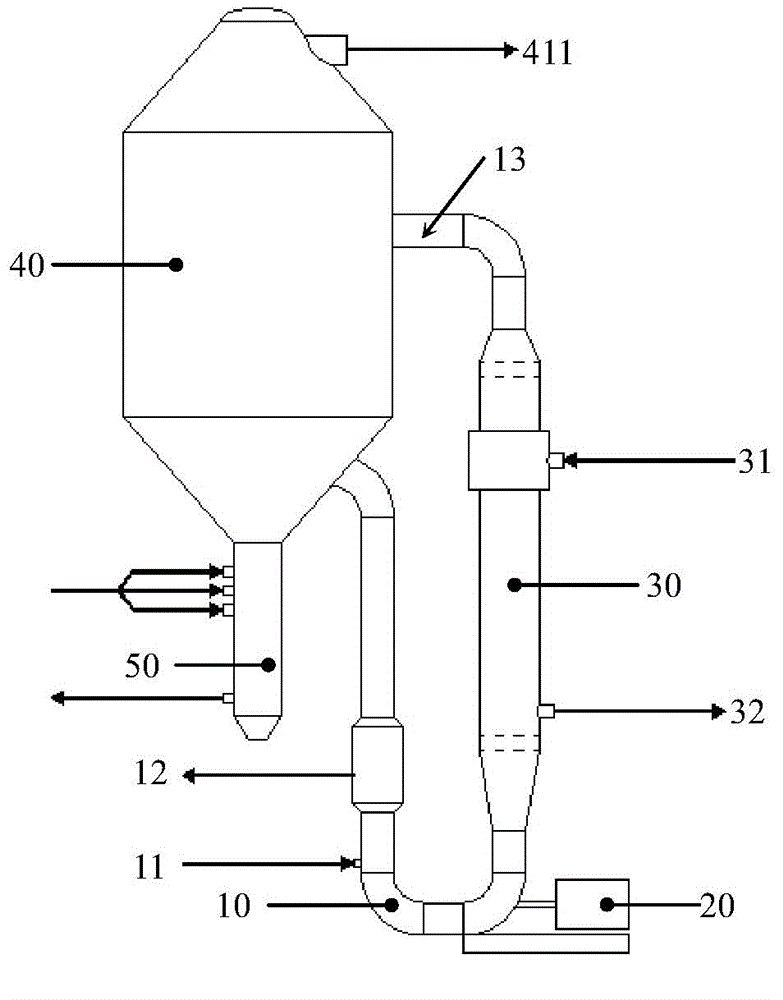

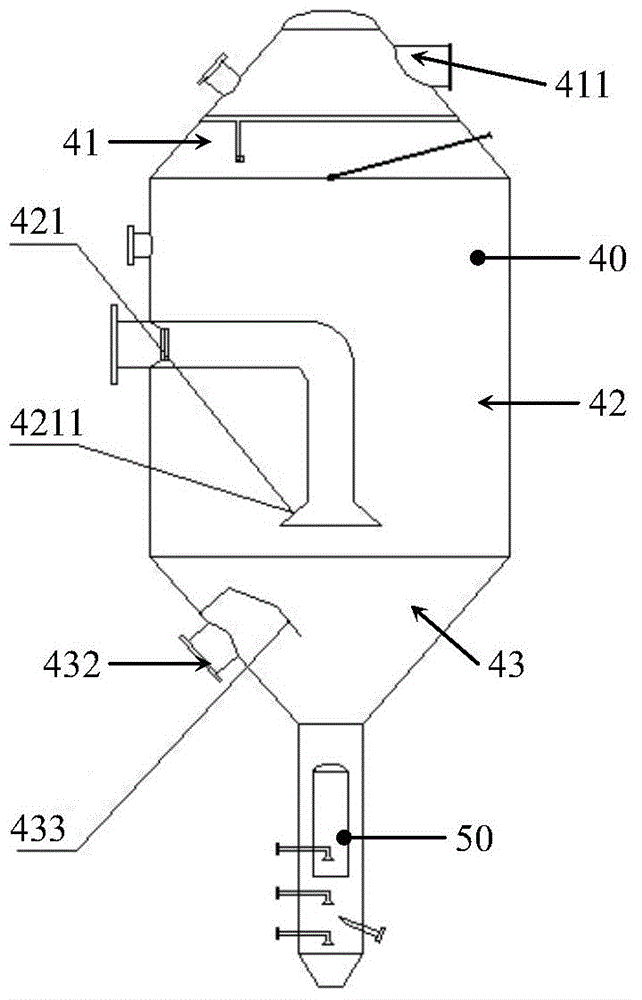

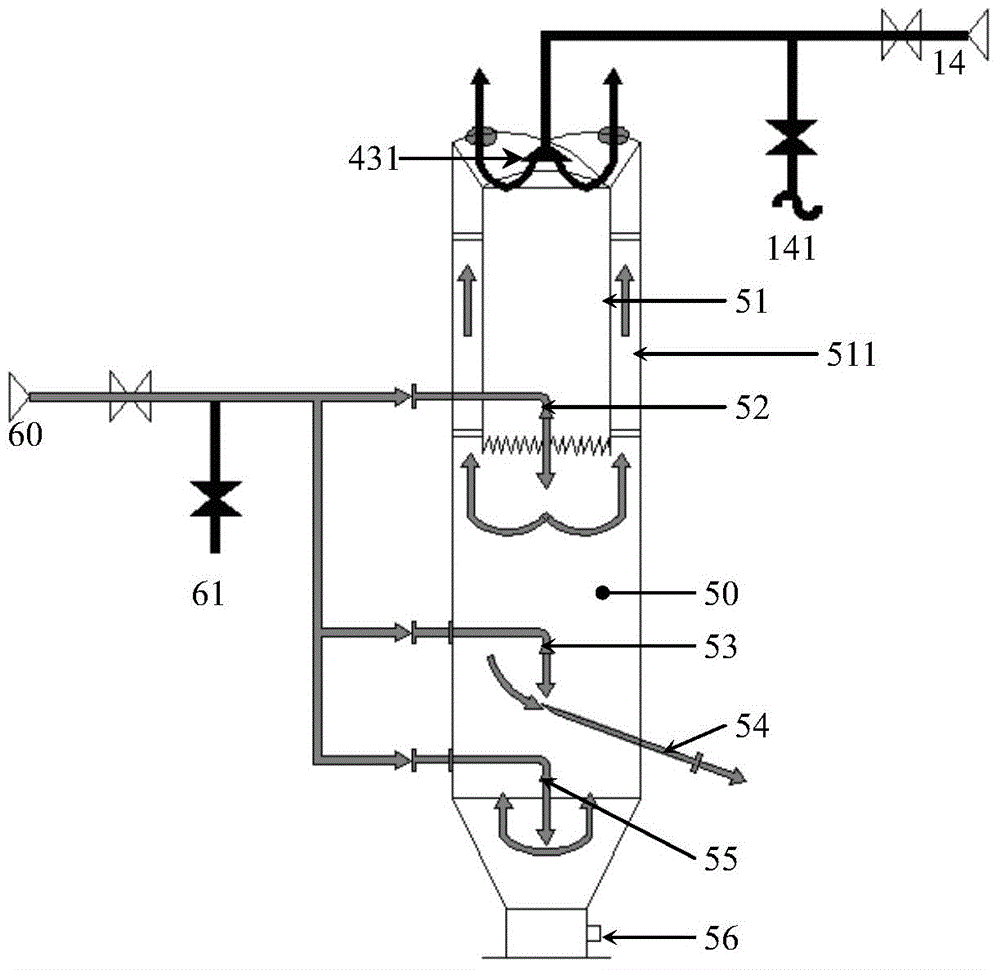

[0045] Such as figure 1 As shown, the embodiment of the evaporation and crystallization salt production equipment of the present invention includes: a circulation pipeline 10 , a circulation pump 20 , a heating device 30 , a flash tank 40 , and a salt washing leg 50 .

[0046] The circulation pipeline 10 is arranged vertically and has a roughly U-shaped structure. The two vertical arms are sealed and connected to the flash tank 40 respectively. Circulation flow within flash tank 40 . A waste water inlet 11 and a mother liquor separator 12 are arranged on the first vertical arm, and the waste water inlet 11 is located below the mother liquor separator 12 . The waste water inlet 11 is used to input the waste water to be extracted into the circulation pipe 10, and the mother liquid separator 12 is used to discharge the waste water mother liquid obtained after the salt is extracted.

[0047] The heating device 30 is arranged on the second vertical arm of the circulation pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com