Method for increasing crystal size of sodium bicarbonate

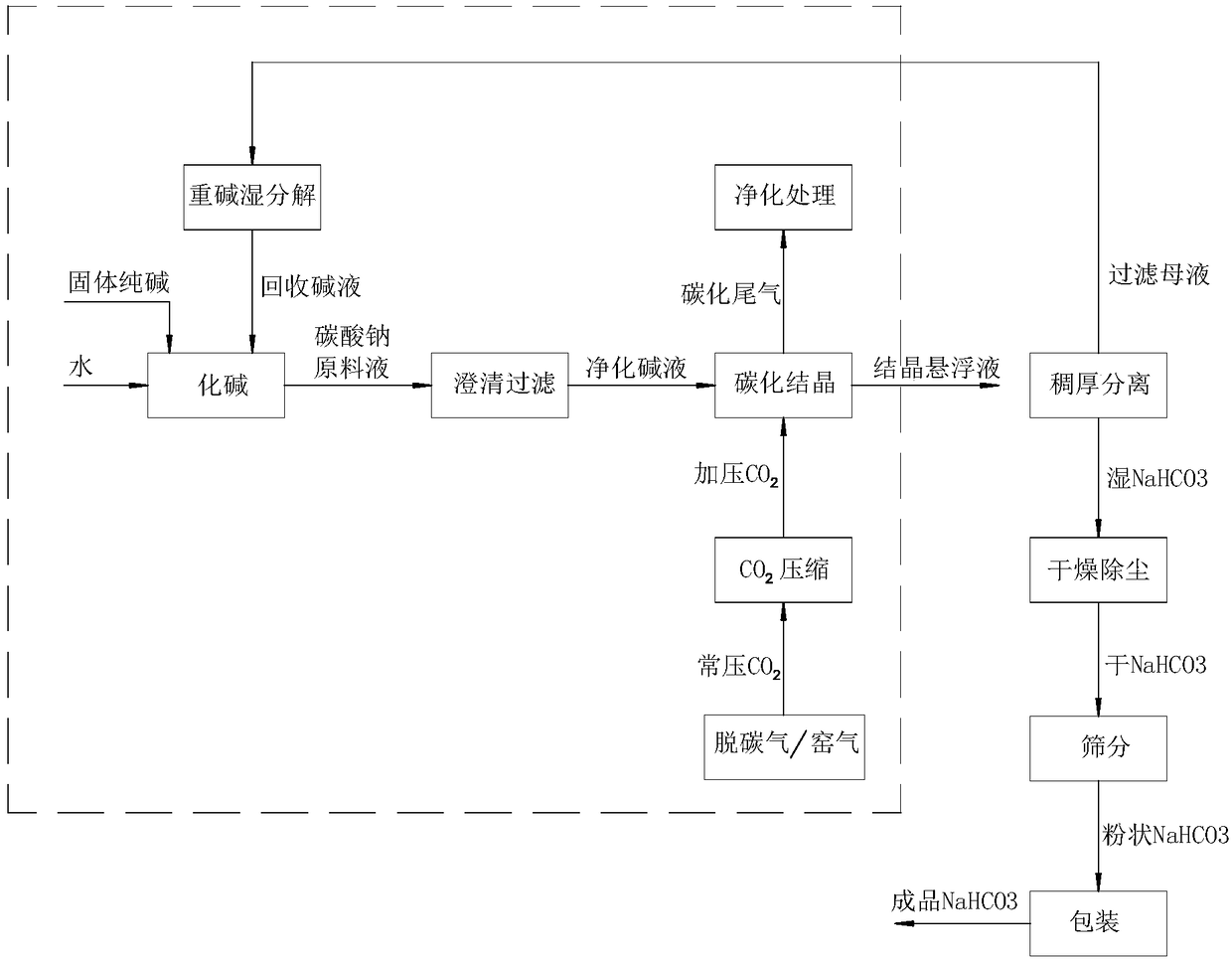

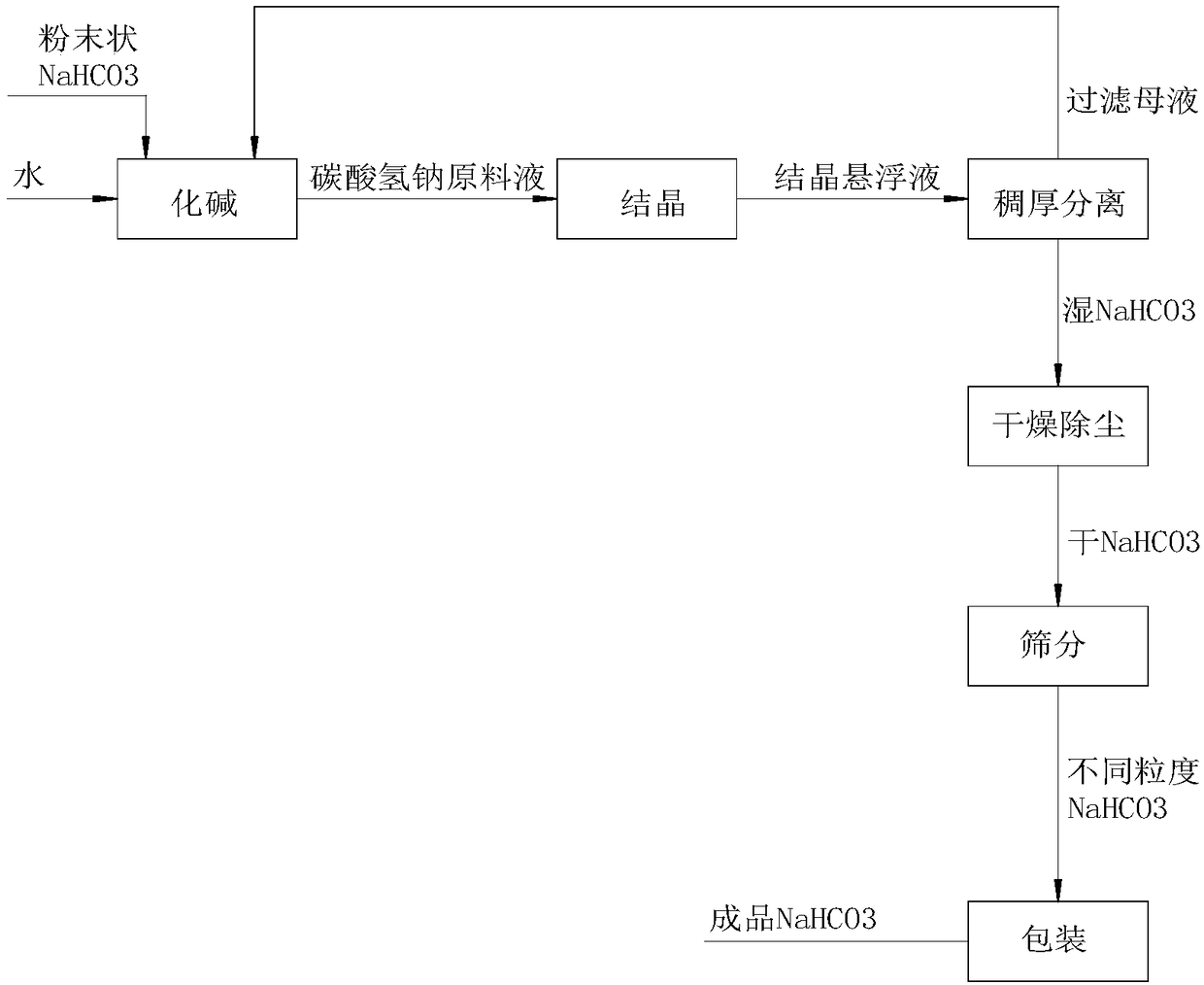

A technology of sodium bicarbonate and crystal size, which is applied in solution crystallization, heat exchange cooling crystallization, alkali metal carbonate shape preparation, etc., and can solve the problems that sodium bicarbonate cannot meet its requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

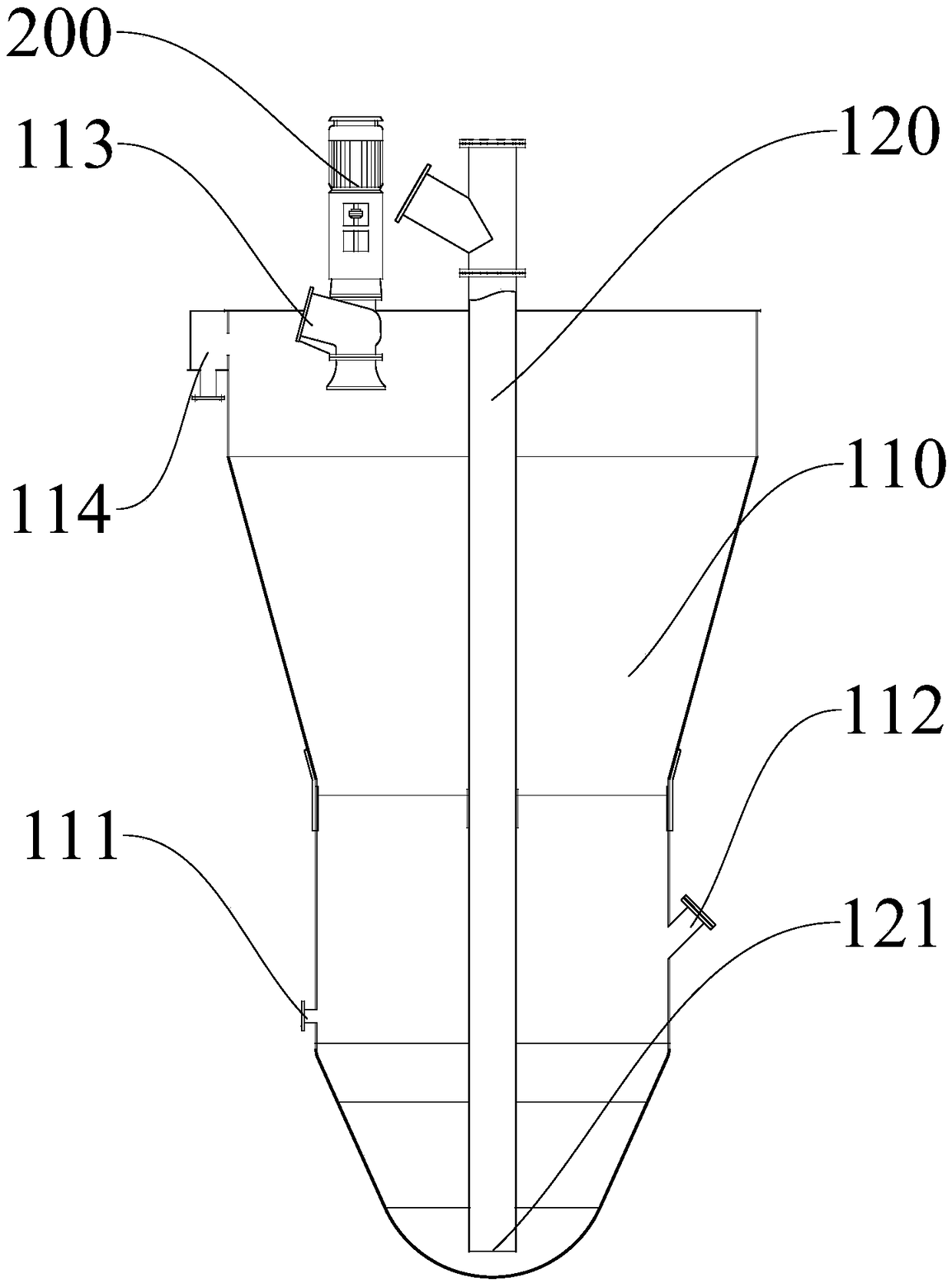

[0054] by figure 1 The shown device for improving the sodium bicarbonate crystal grain size prepares sodium bicarbonate crystals.

[0055] Add 150-mesh (particle size3 A small flow rate of / h is introduced into the tank body 110 with a feed liquid temperature of about 40°C, and the circulating cooling flow rate of the outlet 113 of the circulating cooling feed liquid axial flow pump is set to 2.0m 3 / h, the feed liquid in the tank body 110 is drawn out and cooled to below 40°C by an external cooling device, and returned to the tank body 110 through the outlet 121 of the cooling feed liquid return pipe at the bottom of the central return pipe 120, so as to be slightly lower than the tank body The temperature of the feed liquid in 110 passes through the crystal slurry layer, the supersaturation disappears, and the crystal grows up. at 0.13m 3 The flow rate of / h draws the crystal slurry from the crystal slurry outlet 112, and the excess cleaning liquid in the tank body 110 flo...

Embodiment 2

[0057] by figure 1The shown device for improving the sodium bicarbonate crystal grain size prepares sodium bicarbonate crystals.

[0058] Add 150 mesh (particle size 3 The flow rate of / h is introduced into the tank body 110 with a feed liquid temperature of 40°C, and the circulating cooling flow rate of the outlet 113 of the circulating cooling feed liquid axial flow pump is set to 2.0m 3 / h, the feed liquid in the tank body 110 is drawn out and cooled to below 40°C by an external cooling device and returned to the tank body 110 through the outlet 121 of the cooling feed liquid return pipe at the bottom of the central return pipe 120 to be slightly lower than the tank body 110 The temperature of the inner material liquid passes through the crystal slurry layer, the supersaturation disappears, and the crystal grows up. 3 The flow rate of / h draws the crystal slurry from the crystal slurry outlet 112, and the excess cleaning liquid in the tank body 110 flows out from the overf...

Embodiment 3

[0060] by figure 1 The shown device for improving the sodium bicarbonate crystal grain size prepares sodium bicarbonate crystals.

[0061] Add 150 mesh (grain size 3 The flow rate of / h is introduced into the tank body 110 with a feed liquid temperature of about 40°C, and the circulating cooling flow rate of the outlet 113 of the circulating cooling feed liquid axial flow pump is set to 2.0m 3 / h, the feed liquid in the tank body 110 is drawn out and cooled to below 40°C by an external cooling device, and returned to the tank body 110 through the outlet 121 of the cooling feed liquid return pipe at the bottom of the central return pipe 120, so as to be slightly lower than the tank body The temperature of the feed liquid in 110 passes through the crystal slurry layer, the supersaturation disappears, and the crystal grows up. at 0.17m 3 The flow rate of / h draws the crystal slurry from the crystal slurry outlet 112, and the excess cleaning liquid in the tank body 110 flows out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com