Dense soda ash high-efficiency crystallization production device

A production device and technology of heavy alkali, which is applied in the preparation of alkali metal compounds, alkali metal carbonates, and alkali metal carbonate shapes, etc., can solve the problems of crystal destruction, untimely steam replenishment, and insufficient crystal slurry stirring. , to achieve the effect of brushing clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

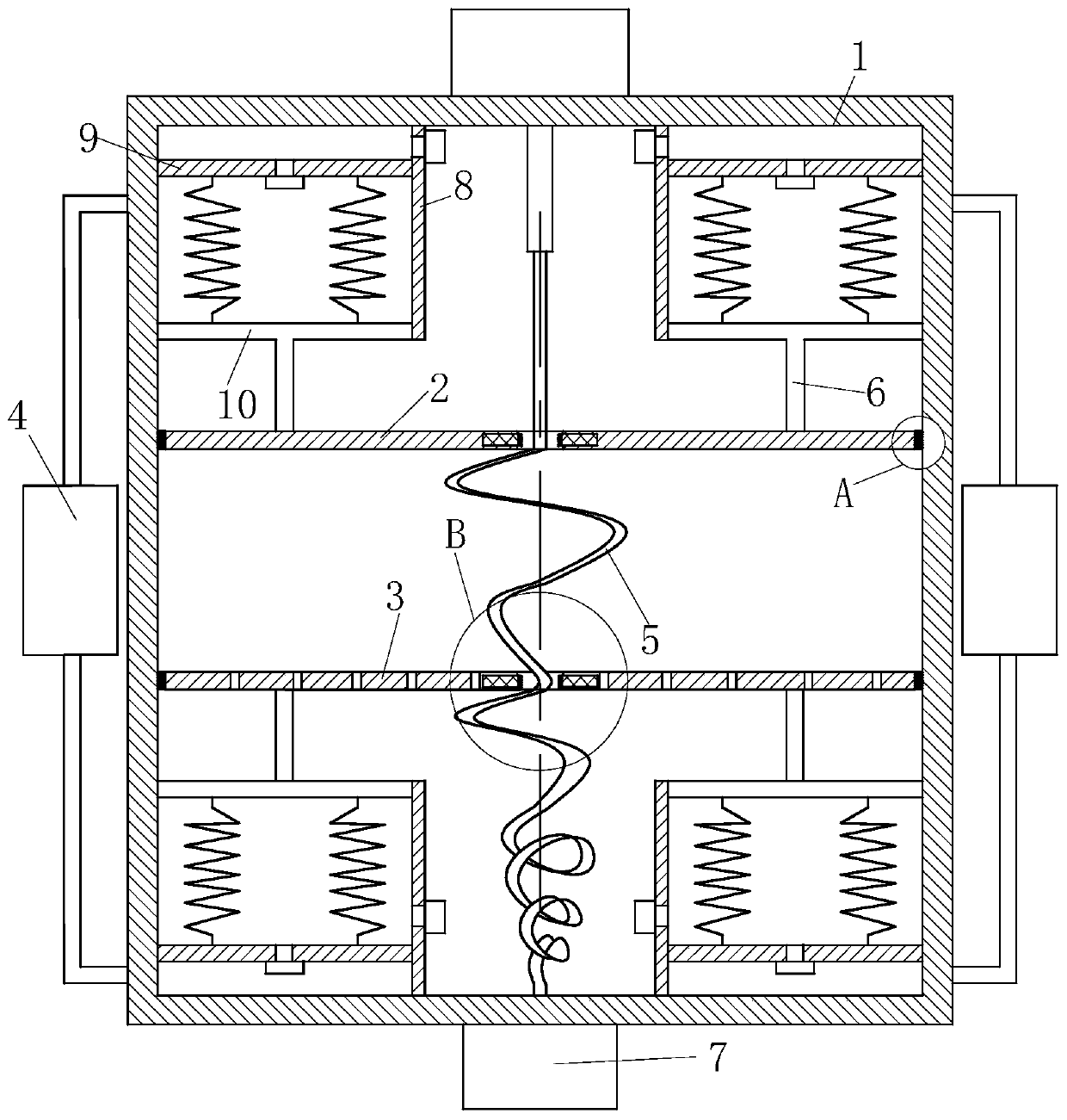

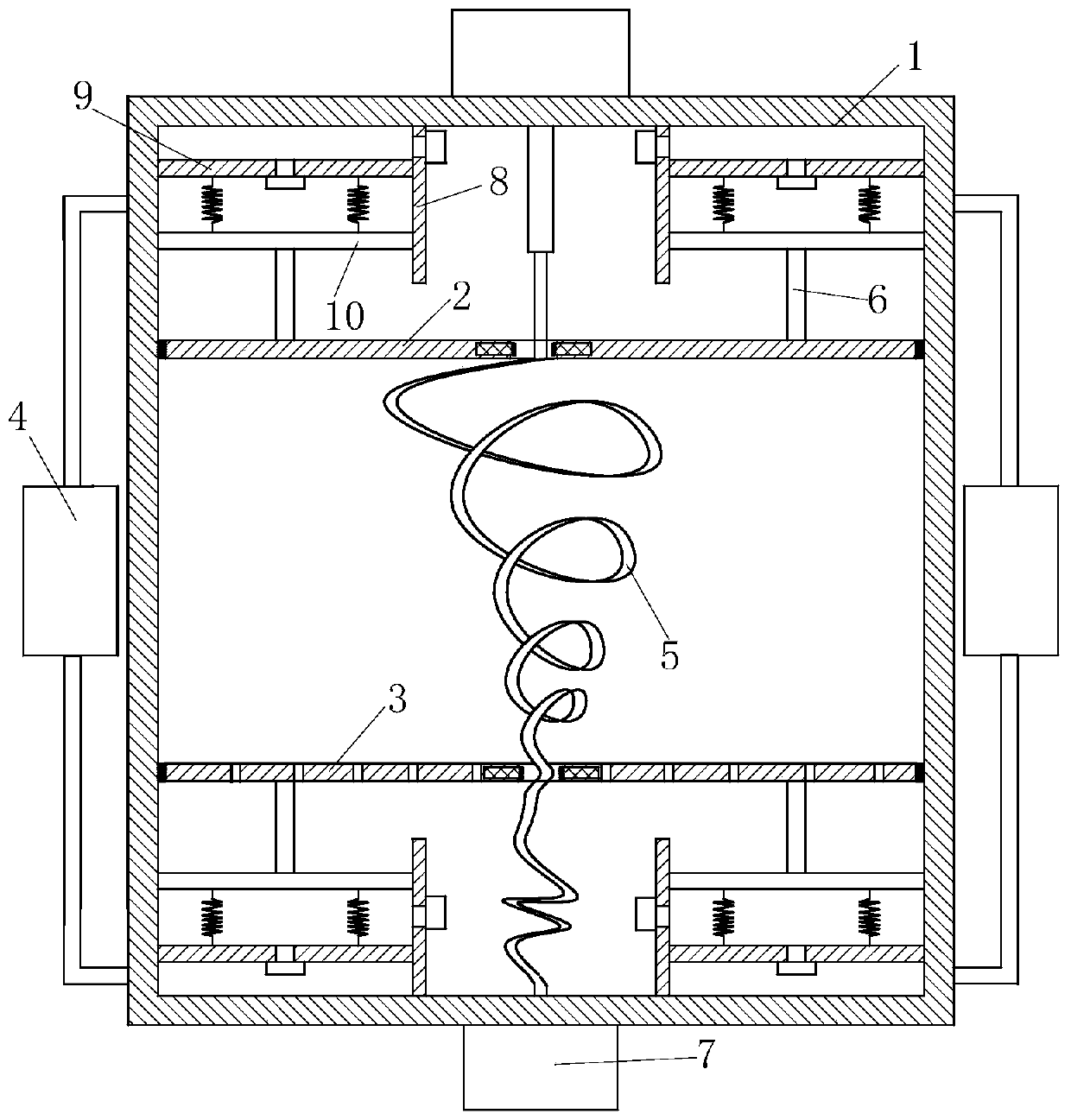

[0028] As an embodiment of the present invention, the upper and lower surfaces of the No. 1 platen 2 and the No. 2 platen 3 are arc-shaped. The upper and lower surfaces of the No. 1 platen 2 and the No. 2 platen 3 are arc-shaped structures, so that when the No. 1 platen 2 and the No. 2 platen 3 slide to the middle of the crystallization furnace 1, the crystal grains in the crystallization furnace 1 are more concentrated.

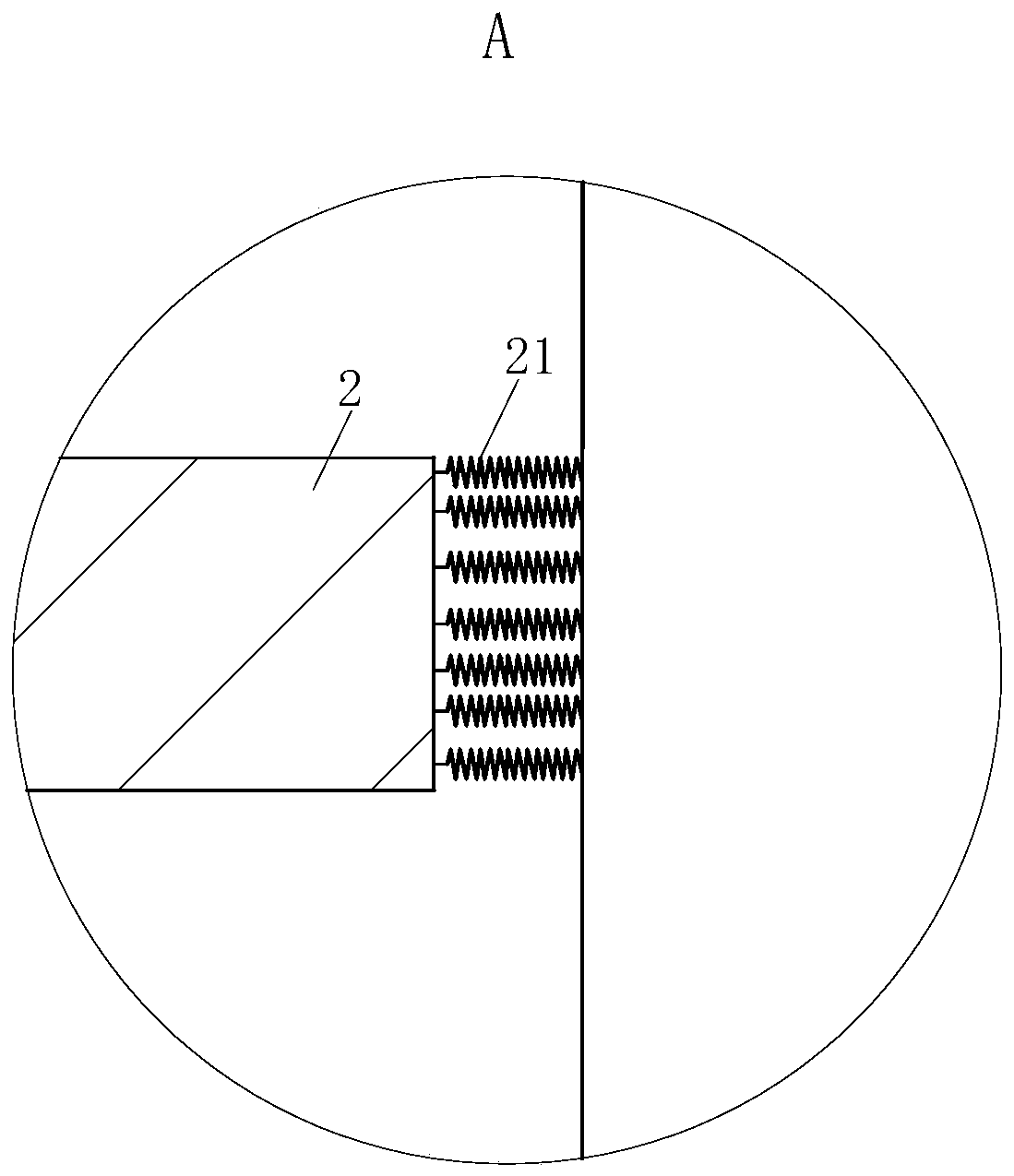

[0029] As an embodiment of the present invention, a No. 1 brush 21 is provided on the outer circumference of the No. 1 platen 2 and the No. 2 platen 3 . During work, the No. 1 platen 2 and the No. 2 platen 3 slide up and down, and the No. 1 brush 21 on the outer circumference of the No. 1 platen 2 and the No. 2 platen 3 can brush the crystals on the side wall of the crystallization furnace 1 to clean the crystallization furnace. 1 The role of side wall cleaning.

[0030] As an embodiment of the present invention, the brush lines of the No. 1 brush 21 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com