Large-particle (granular) semi-batch baking soda crystallization method

A technology of baking soda and large particles, applied in chemical instruments and methods, shape preparation of alkali metal carbonates, alkali metal compounds, etc., can solve problems such as poor fluidity, small particle size, uneven distribution, etc., to achieve good fluidity, The effect of large particle size and less process pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

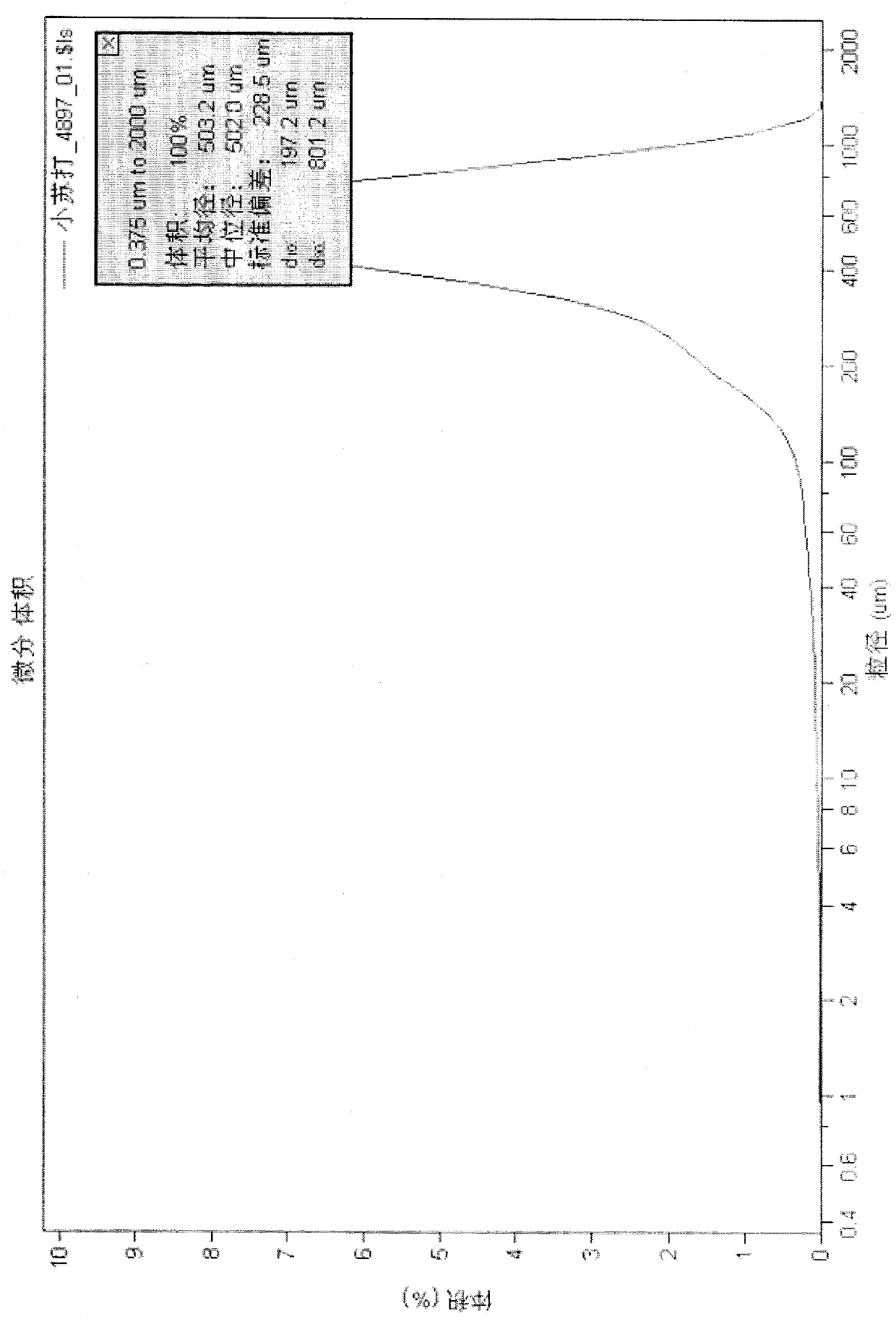

[0026] Dissolve 558g of baking soda in 3kg of an aqueous solution at a temperature of 75°C, and then keep the solution at a constant temperature for 2 hours. After all the solids are dissolved, add 150g of baking soda seeds, start stirring at a speed of 200rpm, and drop The acceleration rate starts to drop the saturated solution of sodium carbonate at 85°C, and at the same time 3 / h into CO 2 , and discharge the fine crystals every half an hour, filter and dry after 5 hours of operation to obtain sodium bicarbonate crystals with an average particle size of 503.2 μm.

Embodiment 2

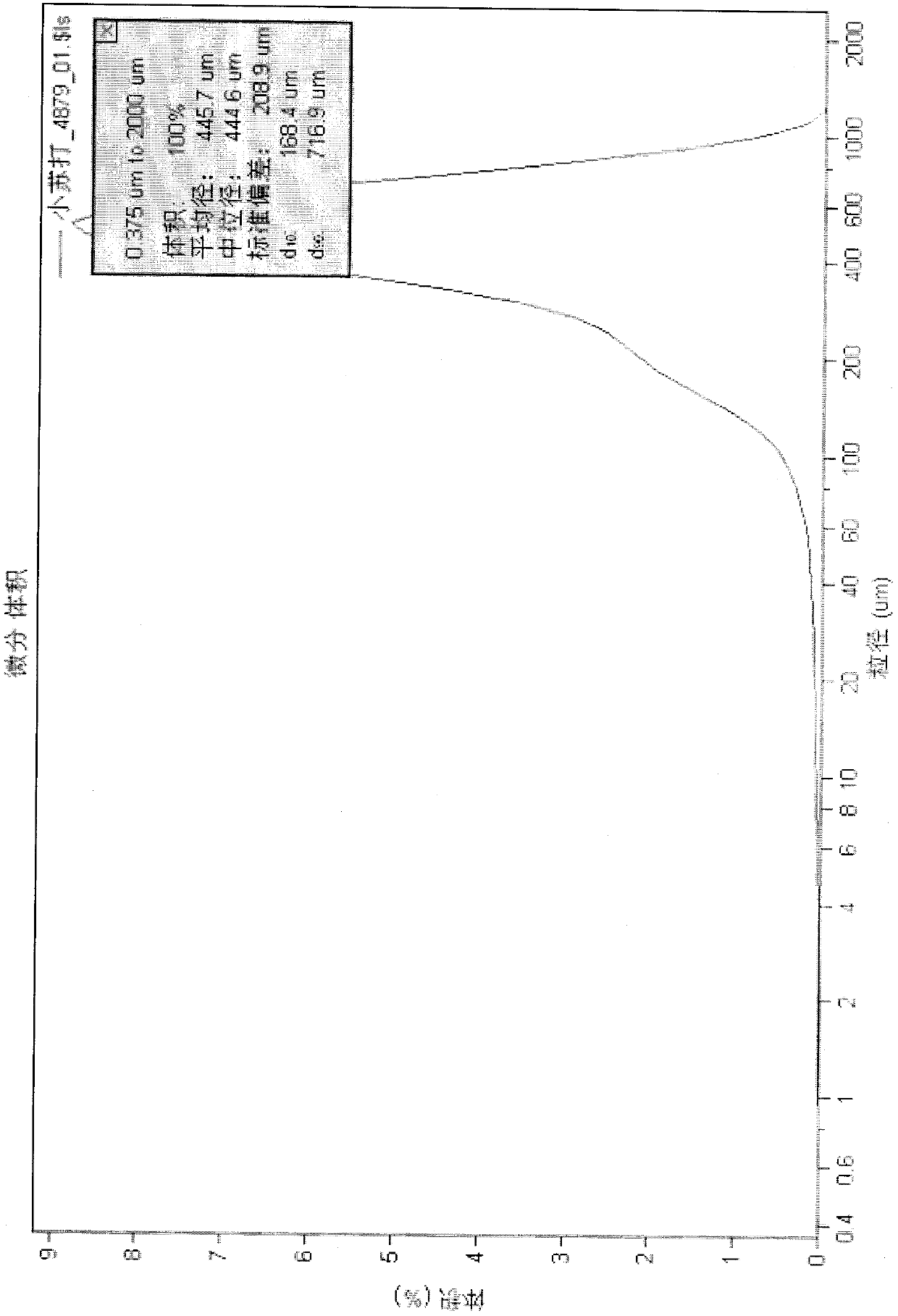

[0028] Dissolve 558g of baking soda in 3kg of an aqueous solution at a temperature of 75°C, and then keep the solution at a constant temperature for 2 hours. After all the solids are dissolved, add 150g of baking soda seeds, start stirring at a speed of 200rpm, and drop The acceleration rate starts to drop the saturated solution of sodium carbonate at 85°C, and at the same time 3 / h into CO 2 , And discharge the fine crystals every half an hour, filter and dry after 5 hours of operation to obtain baking soda crystals with an average particle size of 445.7 μm.

Embodiment 3

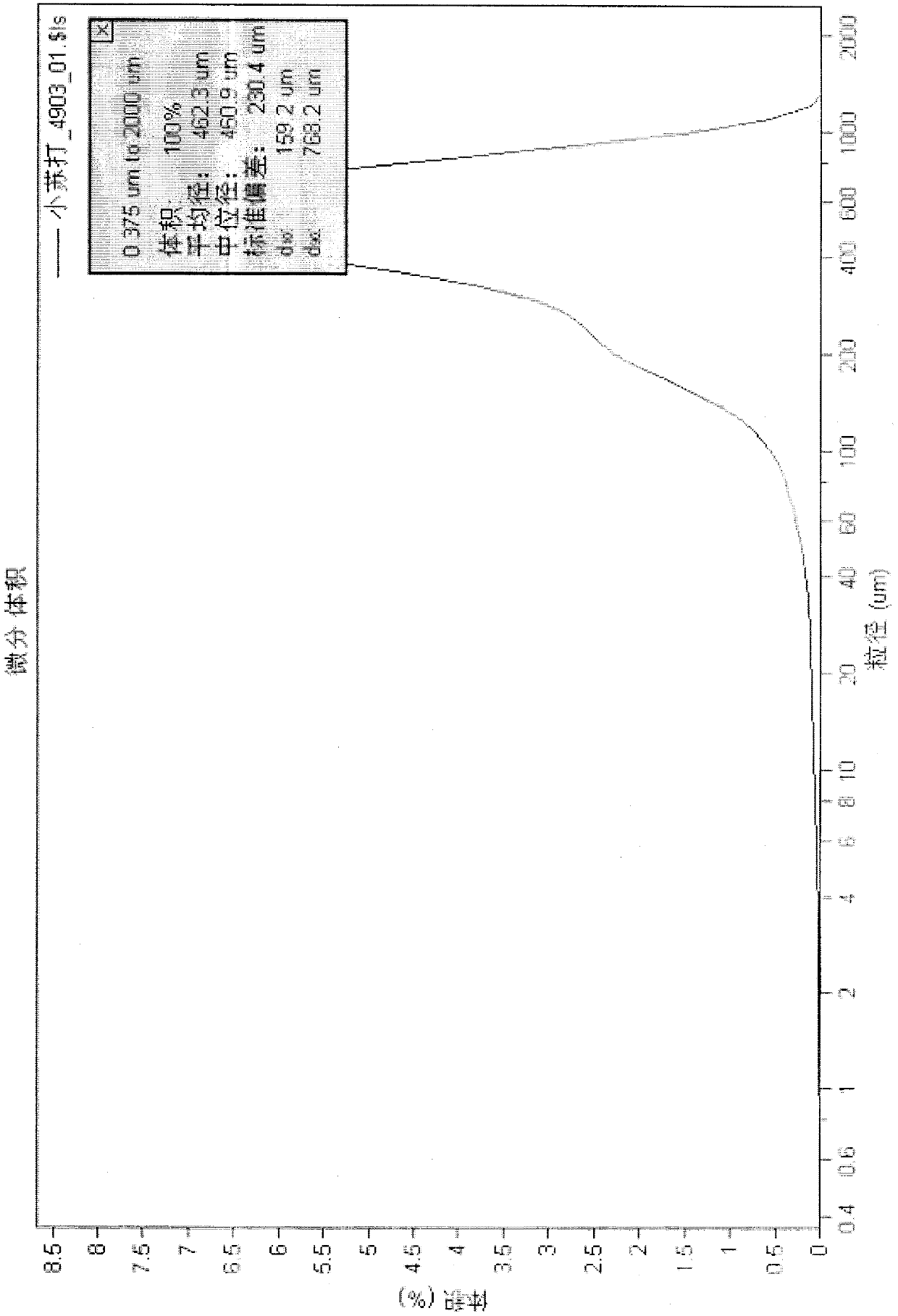

[0030] Dissolve 558g of baking soda in 3kg of an aqueous solution at a temperature of 75°C, and then keep the solution at a constant temperature for 2 hours. After all the solids are dissolved, add 150g of baking soda seeds, start stirring at a speed of 200rpm, and drop The acceleration rate starts to drop the saturated solution of sodium carbonate at 85°C, and at the same time 3 / h into CO 2 , And discharge the fine crystals every half an hour, filter and dry after 6 hours of operation to obtain baking soda crystals with an average particle size of 462.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com