An improved method for controlling aerosol generation in an absorption process of ammonia desulfurization

An absorption process, ammonia desulfurization technology, applied in separation methods, chemical instruments and methods, ammonia compounds, etc., can solve the problems of low crystallinity, low concentration of absorption liquid, instability, etc., to reduce energy consumption and ammonia escape. , the effect of avoiding waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

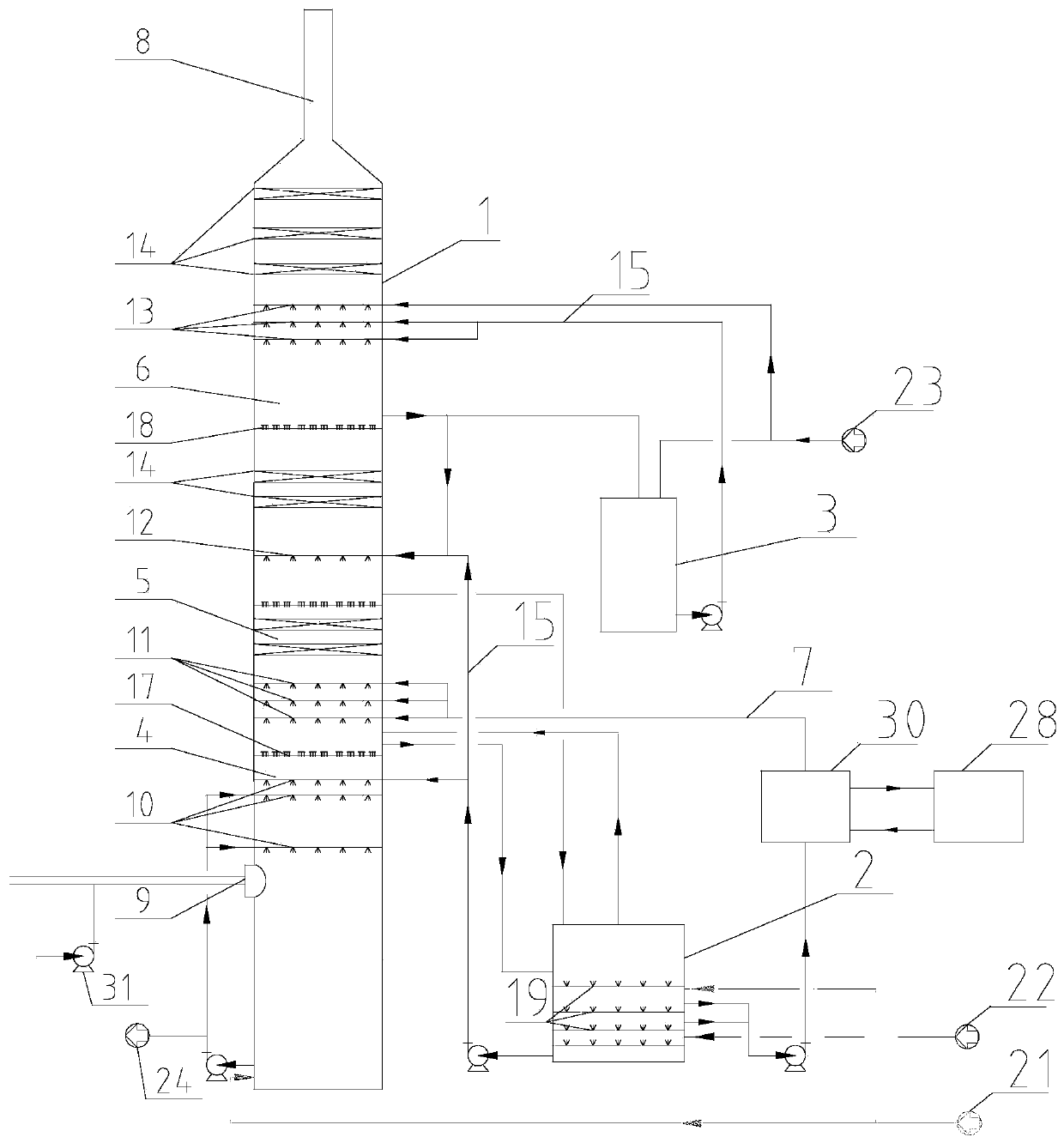

[0117] Such as figure 1 The method for controlling aerosol generation in the absorption process of ammonia desulfurization, uses the absorption circulation liquid containing ammonium sulfite to remove sulfur dioxide in the flue gas, so as to control the generation of aerosol in the absorption process of ammonia desulfurization.

[0118] Through graded solution composition control and reaction condition control, high-efficiency desulfurization and dust removal are realized, and ammonia escape and aerosol generation are controlled while desulfurization is efficient.

[0119] The graded solution component control includes concentration gradient control of ammonium sulfite, ammonium bisulfite, ammonium sulfate or a combination thereof.

[0120] The absorption reaction temperature is 40-55°C, normally 47-51°C.

[0121] The oxygen content of the process gas 9 is ≤12%, under normal circumstances it is 3-8.5%.

[0122] The process gas 9 after initial cooling and purification is in c...

Embodiment 1

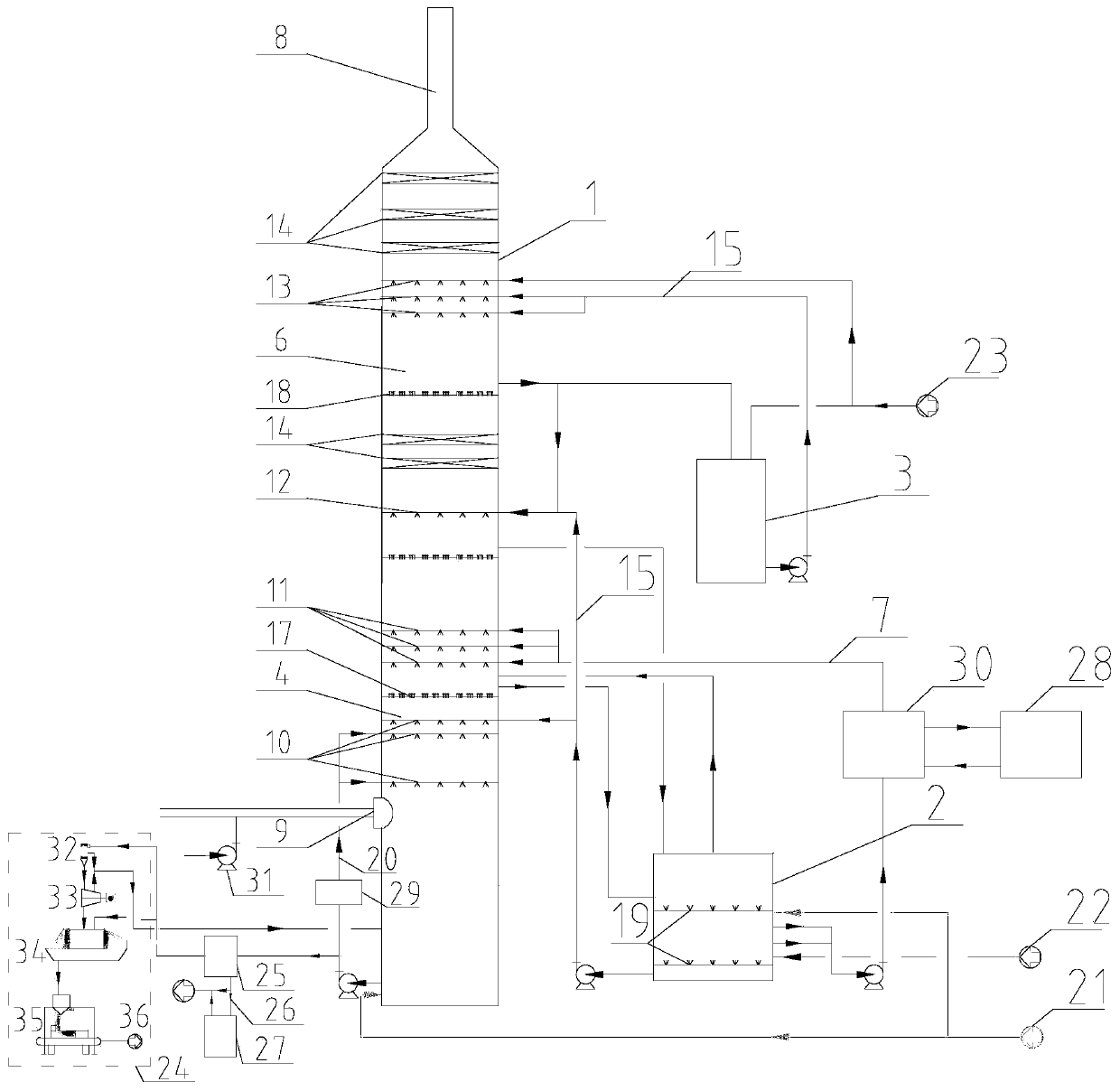

[0148] 1. A method for ammonia desulfurization to control aerosol generation in the absorption process

[0149] The sulfur dioxide in the flue gas is removed by the absorption circulation liquid containing ammonium sulfite to control the generation of aerosol in the absorption process of ammonia desulfurization.

[0150] Through graded solution composition control and reaction condition control, high-efficiency desulfurization and dust removal are realized, and ammonia escape and aerosol generation are controlled while desulfurization is efficient.

[0151] The graded solution component control includes concentration gradient control of ammonium sulfite, ammonium bisulfite, ammonium sulfate or a combination thereof.

[0152] The absorption reaction temperature is controlled at 48-52°C, normally 49.8-50.4°C.

[0153] Through the air distribution of the process fan 31, the oxygen content of the process gas is adjusted to ≤11%, 7-9% under normal conditions, and the air distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com