High salinity wastewater energy-saving evaporative crystallization system and technology thereof

A high-salt wastewater, evaporation and crystallization technology, applied in the directions of evaporation separation and crystallization, crystallization separation, solution crystallization, etc., can solve the problems of low energy utilization rate, many equipments used, high cost, etc., and solve difficult problems with a small number of equipments , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

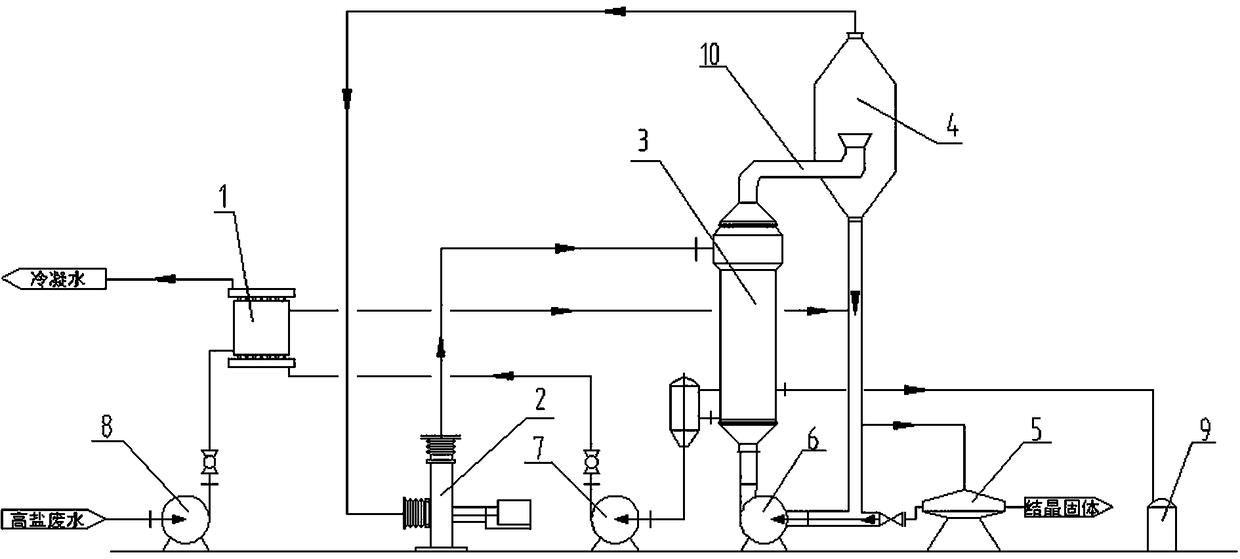

[0037] Embodiment one, taking ammonium sulfate-containing high-salt wastewater as an example:

[0038]The ammonium sulfate wastewater is input into the system through the feed pump 8, and enters the wastewater preheater 1 to be preheated to 30-40°C. After preheating, it enters the tubes installed inside the heating chamber 3. 80-90°C, enter the evaporation chamber 4 from the top of the heating chamber 3, and flash in the evaporation chamber. After flashing, the remaining concentrated wastewater enters the heating chamber 3 through the circulation pump 6 for heating, and then enters the evaporation chamber 4 for flash evaporation after heating. During the cycle evaporation process, ammonium sulfate wastewater is supplemented. After multiple cycles, when the ammonium sulfate solution in the system reaches more than 40%, a supersaturated solution is formed and ammonium sulfate crystals begin to precipitate, and the ammonium sulfate wastewater with crystal precipitation is introduc...

Embodiment 2

[0041] Embodiment two, take sodium chloride-containing wastewater as an example:

[0042] The sodium chloride wastewater is input into the system through the feed pump 8, enters the wastewater preheater 1 to be preheated to 30-40°C, and enters the heating chamber 3 after preheating, and the sodium chloride wastewater reaches 80-90°C after heat exchange through the tubes. ℃, enters the evaporation chamber 4 from the top, and flashes in the evaporation chamber. After flashing, the remaining concentrated wastewater enters the heating chamber 3 to be heated through the circulation pump 6, and then enters the evaporation chamber 4 for flash evaporation after heating. During the cycle evaporation process, Add sodium chloride wastewater. After several cycles, when the sodium chloride solution in the system reaches more than 28%, a supersaturated solution is formed and sodium chloride crystals begin to precipitate, and the sodium chloride wastewater with crystal precipitation is introd...

Embodiment 3

[0045] Embodiment three, take the example that contains sodium gluconate waste water:

[0046] Sodium gluconate waste water enters the system through the feed pump 8, enters the waste water preheater 1 to preheat to 30-40°C, and enters the heating chamber 3 after preheating, and the sodium gluconate waste water reaches 80-90°C after heat exchange through the tubes ℃, enters the evaporation chamber 4 from the top, and flashes in the evaporation chamber. After flashing, the remaining concentrated wastewater enters the heating chamber 3 to be heated through the circulation pump 6, and then enters the evaporation chamber 4 for flash evaporation after heating. During the cycle evaporation process, Add sodium gluconate wastewater, after several cycles, when the sodium gluconate solution in the system reaches more than 55%, a supersaturated solution is formed and sodium gluconate crystals begin to precipitate, and the sodium gluconate wastewater with crystal precipitation is introduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com