Constant-gradient cooling crystallization system and operation method thereof

A cooling crystallization and equal gradient technology, applied in the field of crystallization system, can solve the problems of low pumping efficiency of steam jet pump, high energy consumption of crystallization system operation, large steam consumption, etc., and achieve uniform and stable driving force, low vacuum degree, The effect of uniform crystal particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

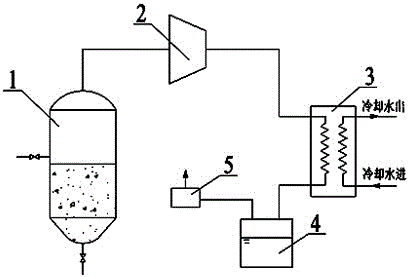

[0018] figure 1 It is the system schematic diagram of this embodiment. As shown in the figure, an isocratic cooling crystallization system includes: a crystallizer 1 , a compressor 2 , a condenser 3 , a condensed water tank 4 , and a vacuum pump 5 . The exhaust port at the top of the crystallizer 1 is connected to the inlet of the compressor 2, the outlet of the compressor 2 is connected to the gas side inlet of the condenser 3, the gas side outlet of the condenser 3 is connected to the inlet of the condensed water tank 4, and the condensed water tank 4 The outlet of the vacuum pump 5 is connected. The compressor 2 is a Roots compressor; the condenser 3 is a plate heat exchanger; the vacuum pump 5 is a water ring vacuum pump. The side wall of the crystallizer 1 is provided with a feed pipe, and the bottom is provided with a discharge pipe.

[0019] When the system is working, first add hot solution to the specified liquid level, turn on the compressor 2 and vacuum pump 5, ...

Embodiment 2

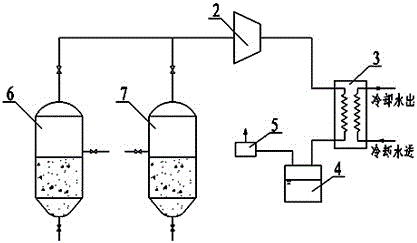

[0021] figure 2 It is the system schematic diagram of this embodiment. As shown in the figure, an isocratic cooling crystallization system includes: a compressor 2 , a condenser 3 , a condensed water tank 4 , a vacuum pump 5 , a first crystallizer 6 , and a second crystallizer 7 . The first crystallizer 6 and the exhaust port at the top of the second crystallizer 7 are all connected to the inlet of the compressor 2, and valves are respectively installed on the connecting pipeline; the compressor 2 outlet is connected to the gas side inlet of the condenser 3, and the condenser The gas side outlet of 3 is connected to the inlet of condensed water tank 4, and the outlet of condensed water tank 4 is connected to vacuum pump 5. The compressor 2 is a screw compressor; the condenser 3 is a shell and tube heat exchanger; the vacuum pump 5 is a water ring vacuum pump. Both the side walls of the first crystallizer 6 and the second crystallizer 7 are provided with feed pipes, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com