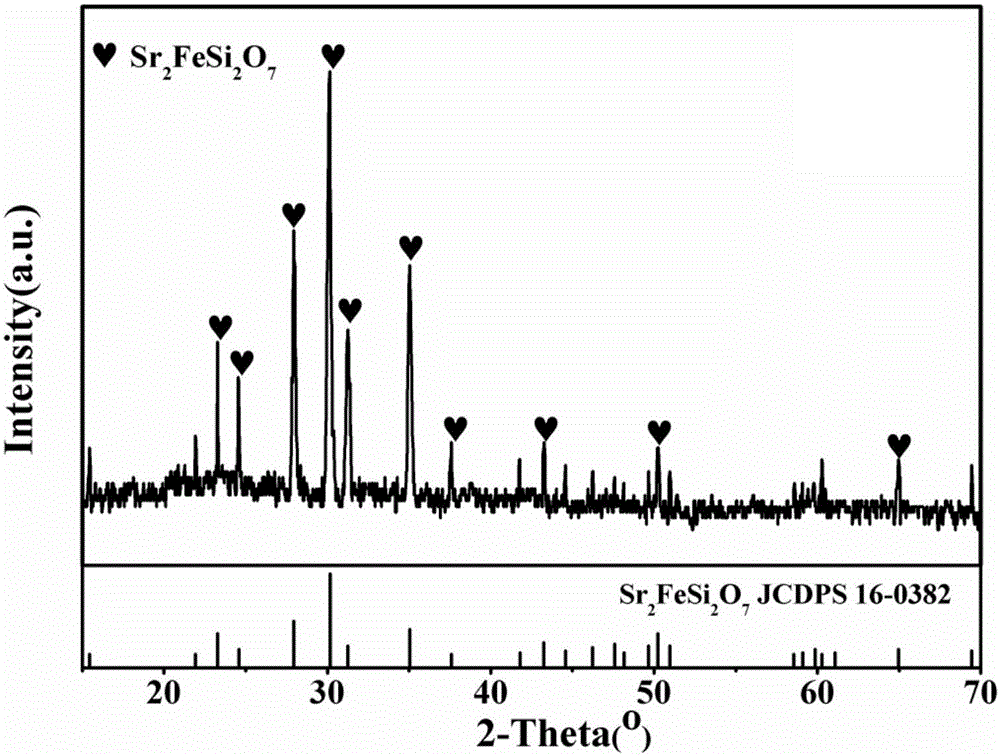

Ferromagnetic Sr2FeSi2O7 microcrystal glass and preparation method thereof

A glass-ceramic and ferromagnetic technology, applied in the field of magnetic glass-ceramic preparation, can solve the problems of long production cycle, easy generation of pores, unfavorable industrial production, etc., and achieve the effect of avoiding uneven composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Put analytically pure strontium carbonate, analytically pure boric acid, SiO 2 , CeO2 and Sb 2 o 3 , so that it meets the requirements of 20 parts of SrO and 20 parts of Fe in terms of parts by mass. 2 o 3 , 20 copies of B 2 o 3 , 40 parts of SiO 2 , 0.3 parts of CeO 2 and 0.2 parts of Sb 2 o 3 , mixed evenly to obtain the batch material;

[0029] Step 2: Add the uniformly mixed batch material into a corundum crucible at 1100°C, heat up to 1350°C for melting to form molten glass, and keep warm at 1350°C for 1 hour to obtain a clear and homogeneous molten glass;

[0030] Step 3: Quickly pour the evenly melted molten glass onto a stainless steel plate, transfer it to an annealing furnace at 500°C immediately after forming, keep it warm for 2 hours, and then cool down to room temperature with the furnace to obtain strontium iron borosilicate glass;

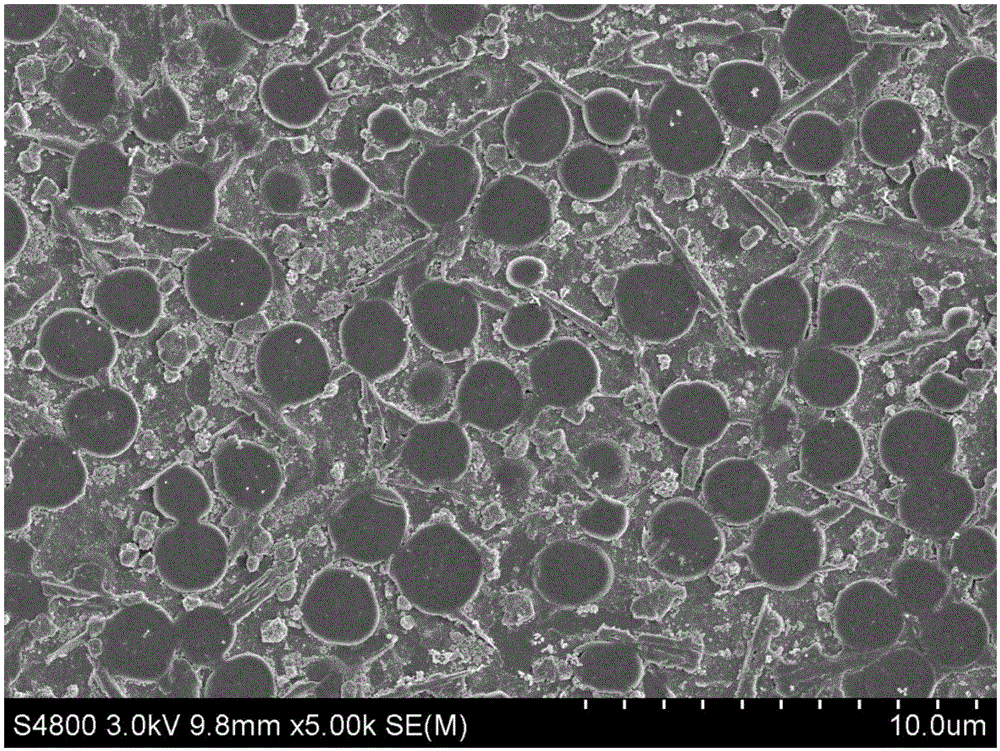

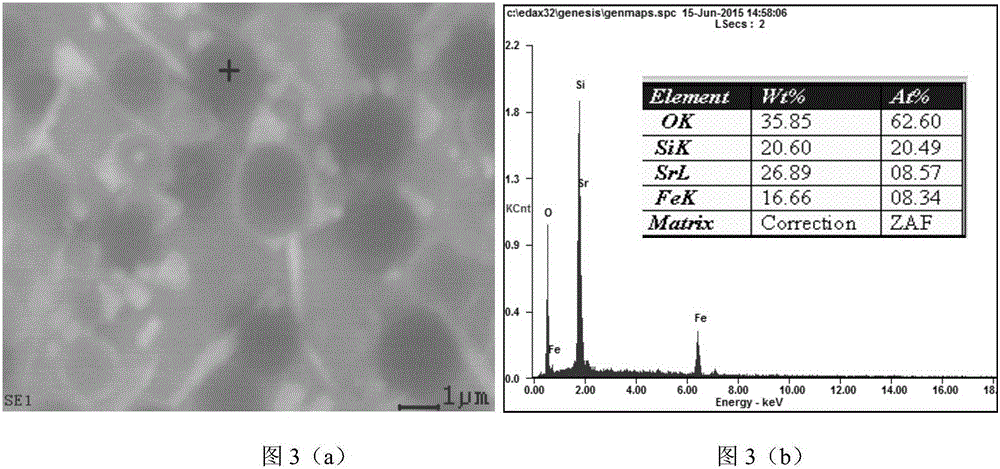

[0031] Step 4: Cut the prepared strontium iron borosilicate glass into a certain shape, place the cut samp...

Embodiment 2

[0037] Step 1: Put analytically pure strontium carbonate, analytically pure boric acid, SiO 2 , CeO 2 and Sb 2 o 3 , so that it meets the requirements of 20 parts of SrO and 20 parts of Fe in terms of parts by mass 2 o 3 , 30 copies of B 2 o 3 , 30 parts of SiO 2 , 0.3 parts of CeO 2 and 0.2 parts of Sb 2 o 3 , mixed evenly to obtain the batch material;

[0038] Step 2: Add the uniformly mixed batch material into a corundum crucible at 1100°C, heat up to 1300°C for melting to form molten glass, and keep warm at 1300°C for 1 hour to obtain a clear and homogeneous molten glass;

[0039] Step 3: Quickly pour the evenly melted molten glass onto a stainless steel plate, transfer it to an annealing furnace at 500°C immediately after forming, keep it warm for 2 hours, and then cool down to room temperature with the furnace to obtain strontium iron borosilicate glass;

[0040] Step 4: Cut the prepared strontium iron borosilicate glass into a certain shape, put the cut sampl...

Embodiment 3

[0042] Step 1: Put analytically pure strontium carbonate, analytically pure boric acid, SiO 2 , CeO 2 and Sb 2 o 3 , so that it meets the requirements of 20 parts of SrO and 20 parts of Fe in terms of parts by mass. 2 o 3 , 40 copies of B 2 o 3 , 20 parts of SiO 2 , 0.3 parts of CeO 2 and 0.2 parts of Sb 2 o 3 , mixed evenly to obtain the batch material;

[0043] Step 2: Add the uniformly mixed batch material into a corundum crucible at 1100°C, heat up to 1250°C for melting to form molten glass, and keep warm at 1250°C for 1 hour to obtain a clear and homogeneous molten glass;

[0044] Step 3: Quickly pour the evenly melted molten glass onto a stainless steel plate, transfer it to an annealing furnace at 500°C immediately after forming, keep it warm for 2 hours, and then cool to room temperature with the furnace to obtain strontium iron borosilicate glass;

[0045] Step 4: Cut the prepared strontium iron borosilicate glass into a certain shape, put the cut sample on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com