3D printing wax wire applied to lost foam casting and preparation method thereof

A technology of lost foam casting and 3D printing, which is applied in the direction of additive processing, etc., can solve the problems of low viscosity, coarse crystals, sharpness, etc., and achieve the effects of high surface finish, improved rigidity and toughness balance, and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

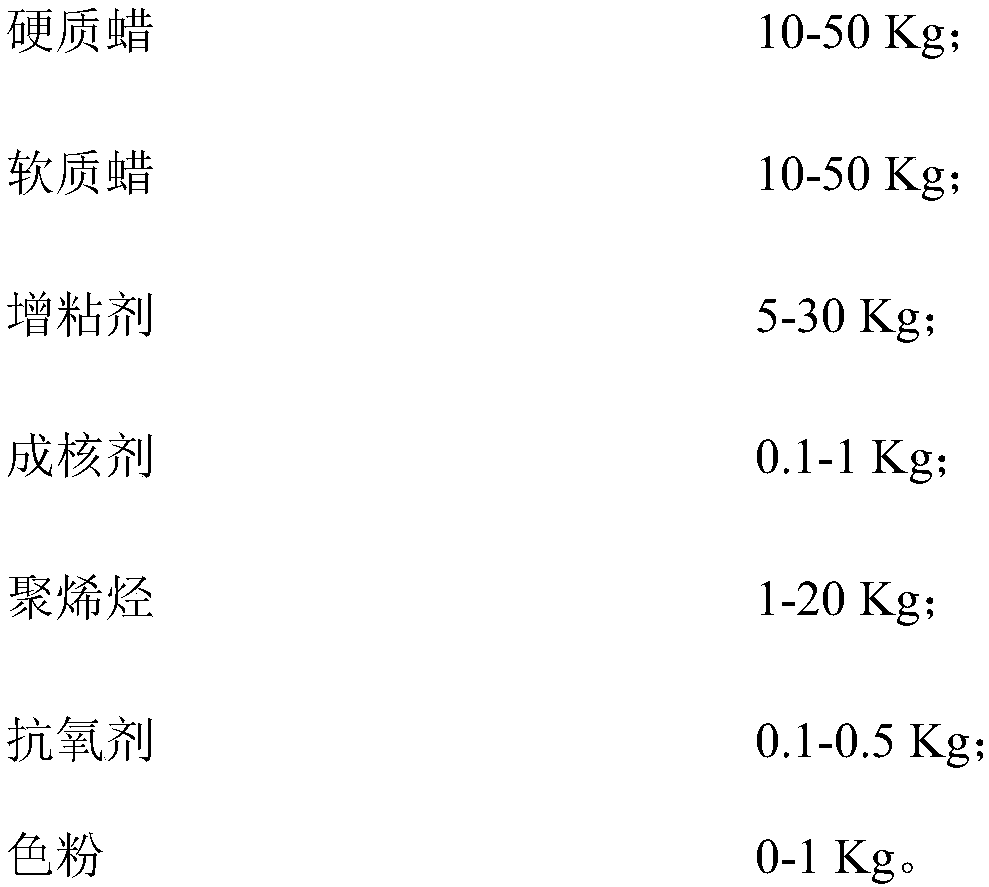

Method used

Image

Examples

preparation example Construction

[0023] The invention also discloses a method for preparing a 3D printing wax thread for lost foam casting, the specific steps are as follows:

[0024] Step 1: Weigh each component raw material according to the component distribution ratio, and mechanically mix each component;

[0025] Step 2: Add the uniformly mixed raw materials of each component to the extruder, draw the wire at 50°C-120°C, cool, air-dry, measure the diameter, pull, store the wire, and wind it to obtain a 3D printing wax wire with uniform wire diameter.

Embodiment 1

[0028] Step S11: Weigh each component raw material according to 50Kg of palm wax, 10Kg of microcrystalline wax, 5Kg of rosin ester, 0.1Kg of sodium stearate, 1Kg of polyolefin, 0.1Kg of hindered phenolic antioxidant, and 1 part of toner. The components are mechanically mixed evenly;

[0029] Step S12: heating and melting the homogeneously mixed raw materials of each component at 70° C. while stirring continuously to obtain a uniform dispersion;

[0030] Step S13: Filter the homogeneous dispersion at a constant temperature of 60° C. to obtain a finished product, wherein the filter paper has a pore size of 1 μm.

Embodiment 2

[0032] Step S21: Weigh the raw materials of each component according to 50Kg of synthetic wax, 50Kg of beeswax, 30Kg of alicyclic hydrocarbon resin, 1Kg of sorbitol, 20Kg of polyolefin, and 0.5Kg of hindered amine antioxidant, and mechanically mix each component;

[0033] Step S22: heating and melting the homogeneously mixed raw materials of each component at 200° C. while stirring continuously to obtain a uniform dispersion;

[0034] Step S23: Filter the homogeneous dispersion at a constant temperature of 120° C. to obtain a finished product, wherein the filter paper has a pore size of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com