Spindle structure of winding machine

A technology of winding machine and main shaft, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of poor rotation accuracy of the main shaft and deformation of the shaft core of the main shaft, so as to improve the rotation accuracy and prolong the service life. Life, the effect of meeting the precision requirements of product processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

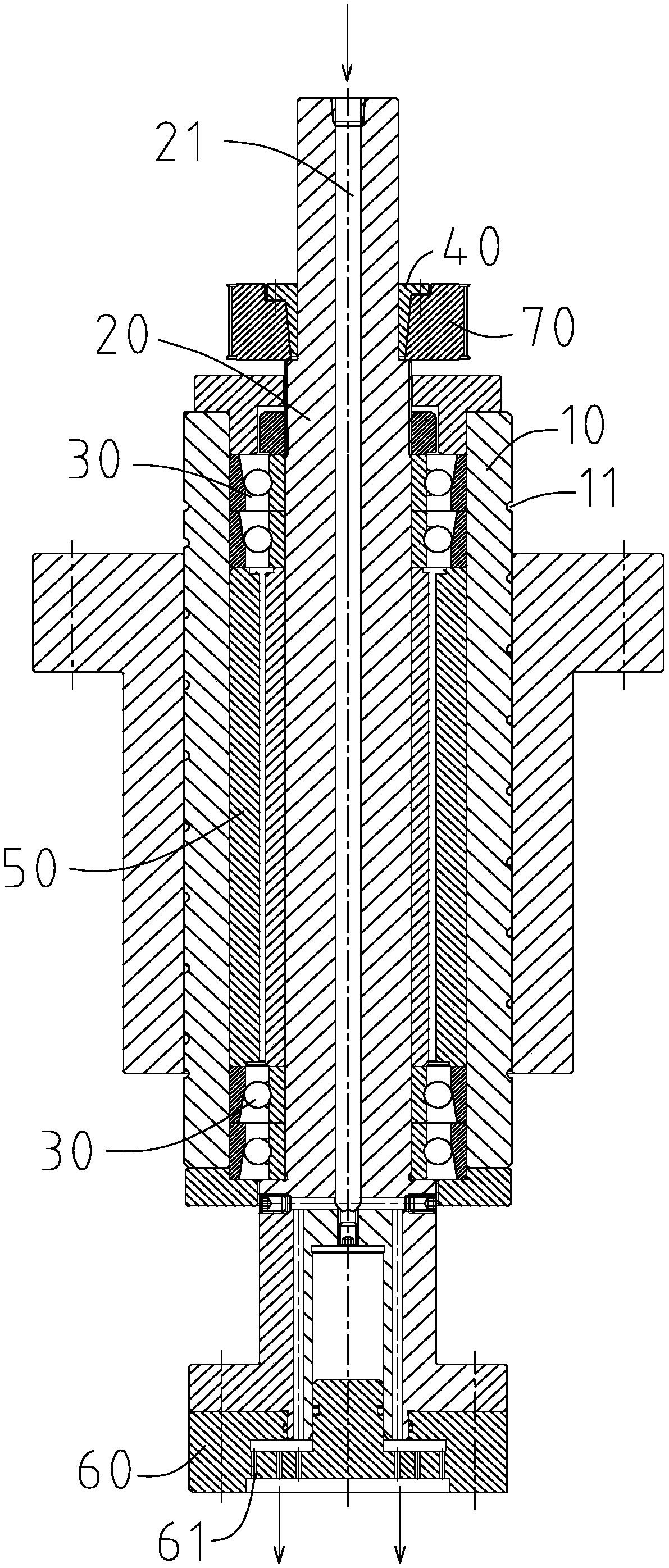

[0017] Such as figure 1 The main shaft structure of a winding machine shown includes a machine body 10, a shaft core 20, a winding mold base 60 and two sets of angular contact bearing assemblies 30; side, and respectively undertake the shaft core 20, at this time, the bearing has a higher rotation accuracy, which improves the rotation accuracy of the main shaft structure of the winding machine; the shaft core 20 is connected in the body 10, and a cooling channel 21 is provided; The wire mold is fixedly connected with the shaft core 20, and is provided with a cooling port 61 communicated with the cooling channel 21; thus, when the cooling gas is introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com