Rare earth magnesium-lithium alloy sheet and preparation method thereof

A technology of lithium alloy and rare earth magnesium, which is applied in the field of rare earth magnesium lithium alloy plate and its preparation, can solve the problems that restrict the application and promotion of magnesium alloy, the strength has not been significantly improved, and the alloy density has been increased, so as to shorten the solidification time and inhibit the crystal grain The effect of growing up and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

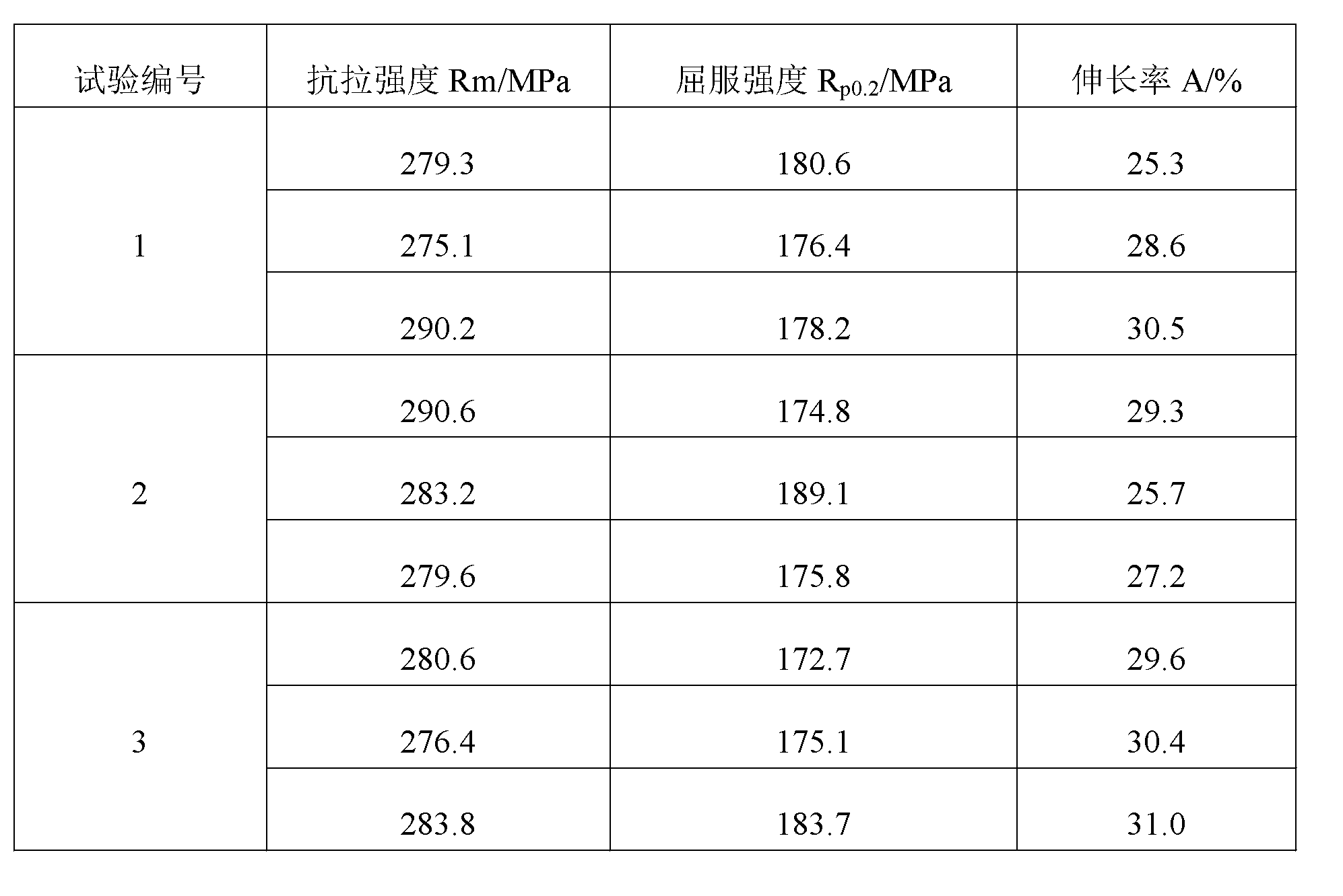

Embodiment 1

[0028] The composition of a kind of magnesium-lithium alloy plate is by weight percentage:

[0029] Li: 11%, Y: 1%, Gd: 1%, Sc: 0.3%, Al: 9%, and the rest is magnesium.

[0030] A method for preparing the magnesium-lithium alloy plate is as follows:

[0031] (1) Preparation: Mg-Li or Al-Li, Mg-Y, Mg-Gd, Mg-Sc or Al-Sc master alloy, pure aluminum, pure magnesium;

[0032] Lithium element is added in the form of magnesium-lithium master alloy or aluminum-lithium master alloy, and its alloy composition is as follows: the lithium content of magnesium-lithium alloy is between 10% and 20 wt%, and the lithium content of aluminum-lithium alloy is between 20 and 40 wt%. The content of yttrium in the master alloy of magnesium and yttrium is greater than or equal to 20 wt%, the content of gadolinium in the master alloy of magnesium and gadolinium is greater than or equal to 20 wt%, and the content of scandium in the master alloy of magnesium and scandium or aluminum and scandium is grea...

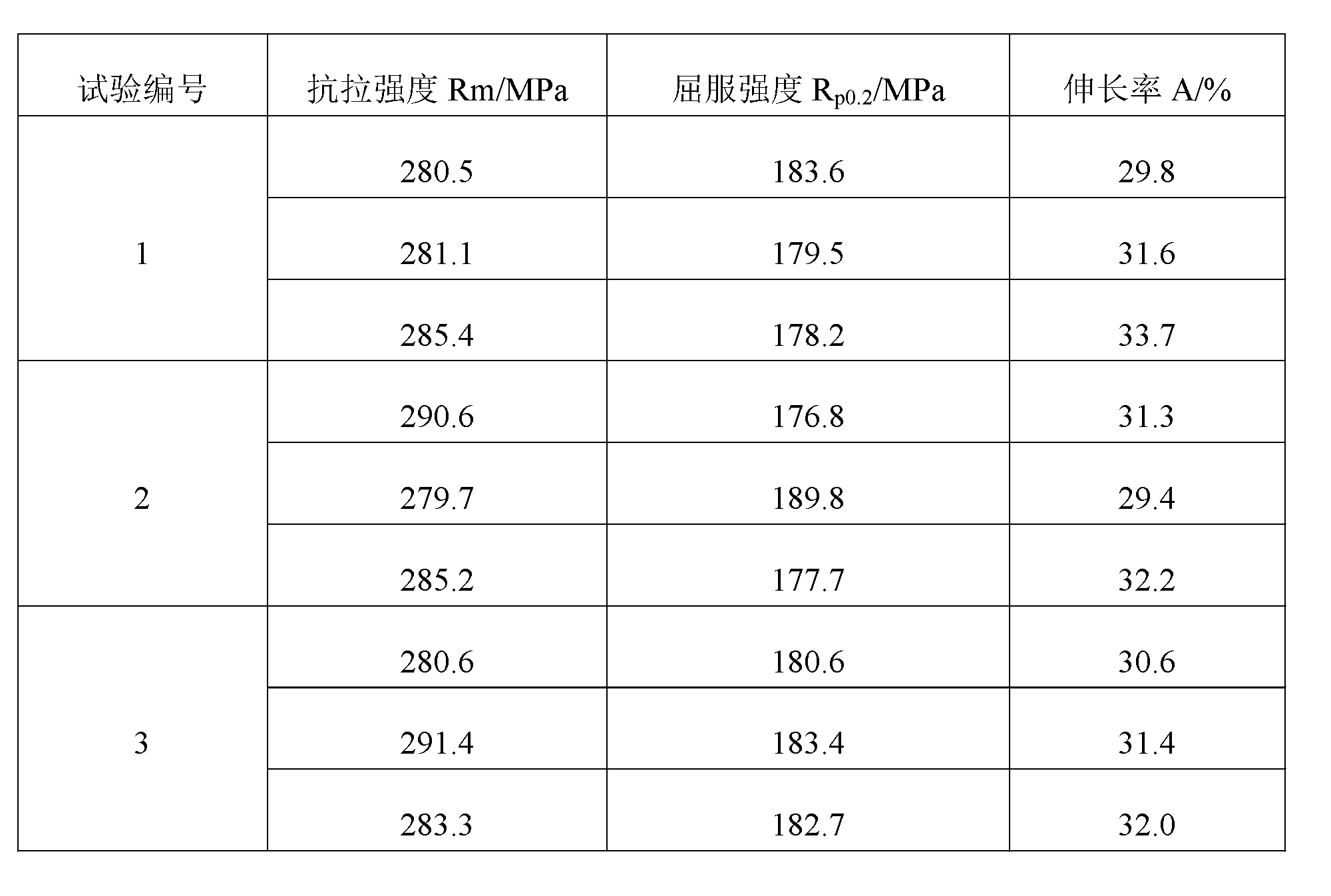

Embodiment 2

[0052] The composition of the magnesium alloy plate is by weight percentage:

[0053] Li: 13%, Y: 1.5%, Gd: 1%, Sc: 0.5%, Al: 9%, and the rest is magnesium.

[0054] The preparation method of the present invention is:

[0055] (1) Preparation: Mg-Li or Al-Li, Mg-Y, Mg-Gd, Mg-Sc or Al-Sc master alloy, pure aluminum, pure magnesium;

[0056] Lithium element is added in the form of magnesium-lithium master alloy or aluminum-lithium master alloy, and its alloy composition is as follows: the lithium content of magnesium-lithium alloy is between 10% and 20 wt%, and the lithium content of aluminum-lithium alloy is between 20 and 40 wt%. ; The content of yttrium in the master alloy of magnesium and yttrium is greater than or equal to 20 wt%, the content of gadolinium in the master alloy of magnesium and gadolinium is greater than or equal to 20 wt%, and the content of scandium in the master alloy of magnesium and scandium or aluminum and scandium is greater than or equal to 5 wt%;

...

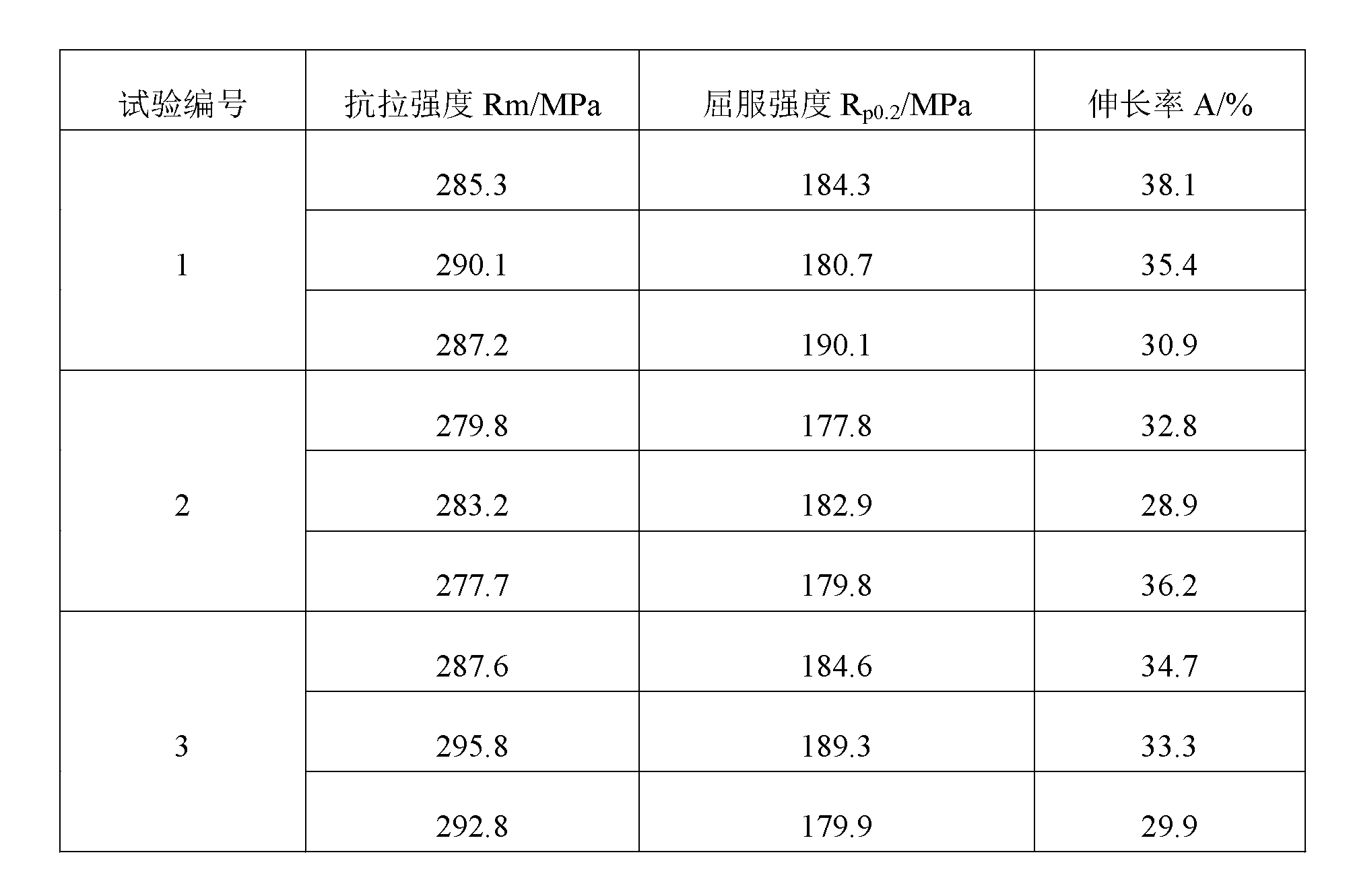

Embodiment 3

[0077] The composition of the magnesium alloy plate is by weight percentage:

[0078] Li: 15%, Y: 1%, Gd: 1.5%, Sc: 0.8%, Al: 9%, and the rest is magnesium.

[0079] The preparation method of the present invention is:

[0080] (1) Preparation: Mg-Li or Al-Li, Mg-Y, Mg-Gd, Mg-Sc or Al-Sc master alloy, pure aluminum, pure magnesium;

[0081] Lithium element is added in the form of magnesium-lithium master alloy or aluminum-lithium master alloy, and its alloy composition is as follows: the lithium content of magnesium-lithium alloy is between 10% and 20 wt%, and the lithium content of aluminum-lithium alloy is between 20 and 40 wt%. ; The content of yttrium in the master alloy of magnesium and yttrium is greater than or equal to 20 wt%, the content of gadolinium in the master alloy of magnesium and gadolinium is greater than or equal to 20 wt%, and the content of scandium in the master alloy of magnesium and scandium or aluminum and scandium is greater than or equal to 5 wt%; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com