Early strength agent using nanometer lithium slag for sulphoaluminate cement and preparation method thereof

A technology of sulphoaluminate cement and early strength agent, which is applied in the field of concrete admixtures, can solve problems such as difficulty in promoting the hydration process of sulphoaluminate, difficulty in large-scale preparation of early strength agent, and huge lithium slag stockpile. , to achieve the effect of facilitating the bonding of the interface, the strength does not shrink, and the effect of promoting the hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

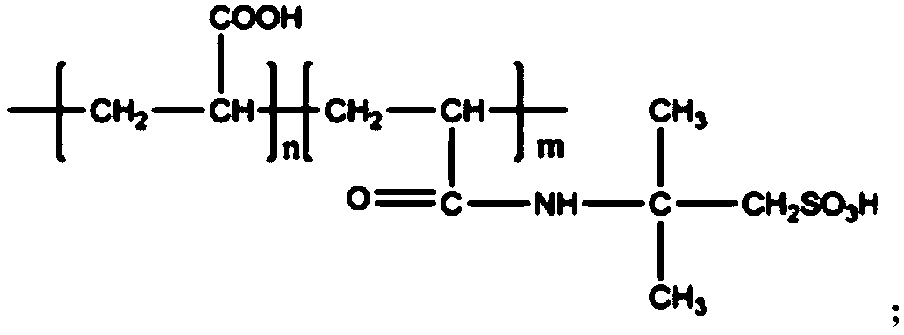

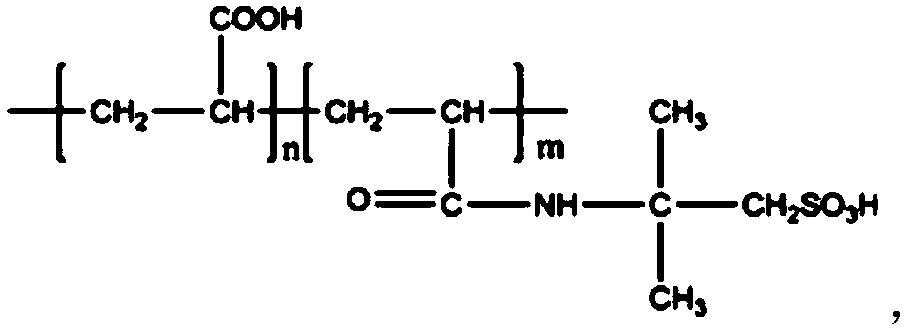

[0023] The preparation method of the preparation method of the dispersant used in this embodiment is as follows: 50 parts by weight of acrylic acid (AA), 50 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 100 parts by weight of water are mixed uniformly. Solution, heat the mixed solution to 50°C, and then add dropwise initiator ammonium persulfate solution with a concentration of 0.1% (the amount of ammonium persulfate is 0.1% of the total amount of AA and AMPS) and 0.6% of the The chain transfer agent thioglycolic acid solution (the amount of thioglycolic acid is 1% of the total amount of AA and AMPS), the dripping time is 1h, and the dispersant is obtained after the dripping is completed.

[0024] After testing, the molecular structural formula of the polymer in the obtained dispersant is:

[0025]

[0026] Where m=1 and n=3.

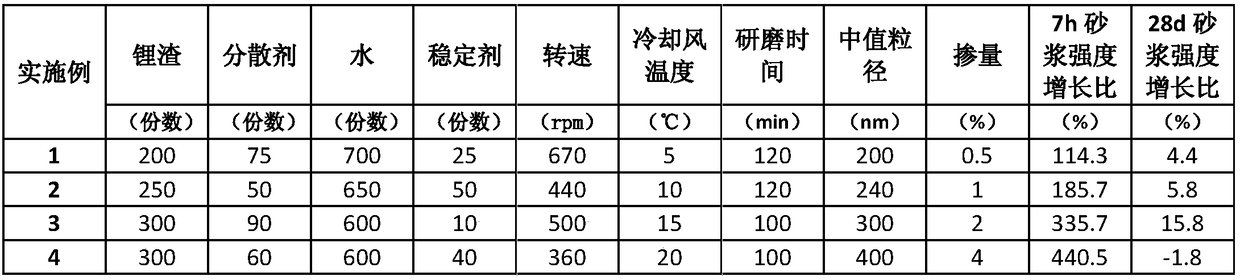

Embodiment 1-4

[0028] The preparation of nanometer lithium slag early strength agent for sulphoaluminate cement, the specific steps are as follows: the lithium slag, dispersant, stabilizer (commercially available konjac gum, mass concentration is 0.1%) and deionized water according to Table 1 Add zirconia grinding balls to the planetary ball mill. The amount of zirconia grinding balls is 10 times the amount of lithium slag. The gradation mass ratio of zirconia grinding balls: 2.5mm:1.4mm:0.6mm=1:1:2. Nano lithium slag early strength agent for sulphoaluminate cement. A laser particle size analyzer was used to measure the particle size of the nano lithium slag early strength agent prepared in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com