Strip steel and production method and system thereof

A strip and hot continuous rolling technology, applied in the field of steel, can solve the problems of accelerated consumption of scarce resources, complicated management, low process efficiency, etc., to achieve the effects of diversified production, cleanliness control, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

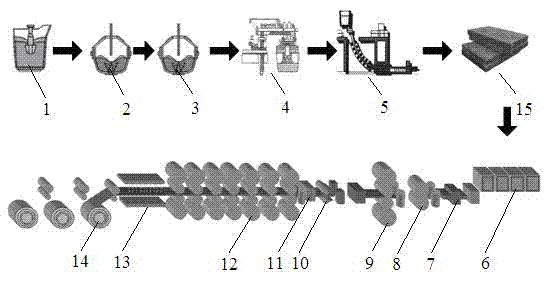

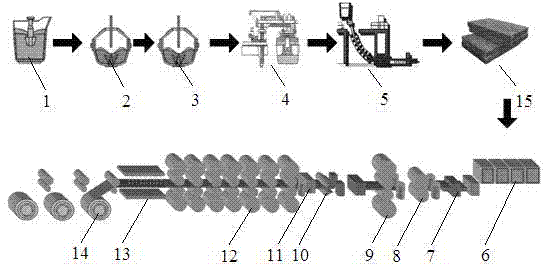

[0029] See attached figure 1 , the molten iron is desulfurized by KR desulfurization device 1, KR deS; converter 2 for deP and Si; smelting converter 3 for deC; LF refining device 4 for refining; Si0.21%, Mn1.34%, P0.014%, S0.003%, V0.021%, Ti0.017%, Alt 0.047%, the rest is Fe and impurity slab 15, the carbon equivalent of slab 15 is 0.39, and the specification is thickness × width = 230mm × 1500mm. Then, make the slab pass through the 2250 hot continuous rolling wide strip mill, that is, successively pass through the heating furnace 6, the rough descaling machine 7, the two-roll rough rolling mill 8, the four-roll rough rolling mill 9, the cutting head flying shear 10, the fine descaling machine 11, The finishing rolling unit 12, the laminar flow cooling device 13, and the coiler 14 carry out continuous hot rolling, wherein the temperature of the heating furnace 6 is 1260° C., and the heating time is 3.5 hours. The finish rolling temperature of the finishing rolling unit 12 ...

Embodiment 2

[0032] See attached figure 1 , the molten iron is desulfurized by KR desulfurization device 1, KR deS; converter 2 for deP and Si; smelting converter 3 for deC; LF refining device 4 for refining; Si0.21%, Mn1.34%, P0.014%, S0.003%, V0.021%, Ti0.017%, Alt0.047%, the rest is Fe and impurity slab 15, the carbon of slab 15 The equivalent is 0.39, and the specification is thickness × width = 230mm × 1500mm. Then, make the slab pass through the 2250 hot continuous rolling wide strip mill, that is, successively pass through the heating furnace 6, the rough descaling machine 7, the two-roll rough rolling mill 8, the four-roll rough rolling mill 9, the cutting head flying shear 10, the fine descaling machine 11, The finishing rolling unit 12, the laminar flow cooling device 13, and the coiler 14 carry out continuous hot rolling, wherein the temperature of the heating furnace 6 is 1240° C., and the heating time is 3.5 hours. The finish rolling temperature of the finishing rolling unit ...

Embodiment 3

[0035]The molten iron is desulfurized by KR desulfurization device 1, desulfurized by KR; deP and Si by converter 2; decarbonized by smelting converter 3; refined by LF refining device 4; .21%, Mn1.29%, P0.013%, S0.001%, V0.021%, Ti0.019%, Alt0.05%, the rest is Fe and impurity slab 15, the carbon equivalent of slab 15 is 0.39, and the specification is thickness × width = 230mm × 1600mm. Then, make the slab pass through the 2250 hot continuous rolling wide strip mill, that is, successively pass through the heating furnace 6, the rough descaling machine 7, the two-roll rough rolling mill 8, the four-roll rough rolling mill 9, the cutting head flying shear 10, the fine descaling machine 11, The finishing rolling unit 12, the laminar flow cooling device 13, and the coiler 14 carry out continuous hot rolling, wherein the temperature of the heating furnace 6 is 1200°C, the heating time is 3.0 hours, the finishing rolling temperature of the finishing rolling unit 12 is 840°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com