Rear-earth aluminum, silicom and calcium ferroalloy and preparation method of rear-earth aluminum, silicom and calcium ferroalloy

A technology of silicon-calcium-iron alloy and rare earth aluminum, which is applied in the field of ferroalloy and can solve problems such as steel pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

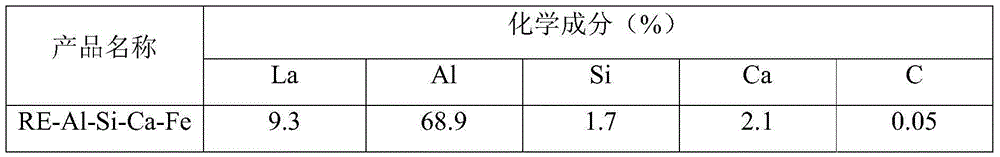

Embodiment 1

[0021] (1) 75% aluminum ingot: 20% rare earth: 5% calcium metal. Melt the aluminum ingot in an induction furnace with an argon protective atmosphere. After the melting is complete, add calcium and rare earth (the main component of the rare earth is lanthanum). The smelting temperature is controlled at 1000°C, mixed evenly for 10 minutes, and then cast into a rare earth aluminum-calcium master alloy. .

[0022] (2) 30% scrap steel: 5% ferrosilicon: 65% aluminum ingot. High-quality plate scrap steel is melted in an intermediate frequency furnace. After melting, ferrosilicon (75% Si content) is added for deoxidation and alloying, and then aluminum ingots are added, and the temperature is controlled at 1250°C. After the aluminum ingot is melted, the rare earth aluminum-calcium master alloy obtained in the first step is added, and the ingredients are uniformly mixed for 10 minutes, and the temperature of the alloy out of the furnace is controlled at 1100°C. It is cast into alloy ...

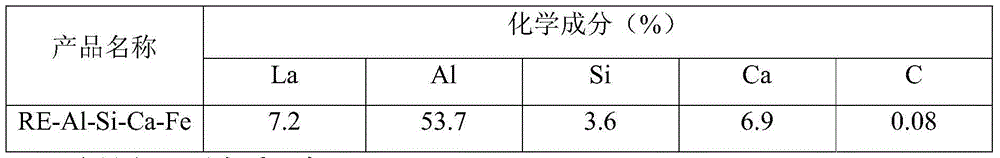

Embodiment 2

[0027] (1) 70% aluminum ingot: 15% rare earth: 15% calcium metal. The aluminum ingot is melted in an induction furnace with an argon protective atmosphere. After melting, calcium and rare earth alloys are added. The smelting temperature is controlled at 1000°C, mixed evenly for 10 minutes, and then cast into a rare earth aluminum calcium master alloy with a particle size of 60mm×60mm ×40mm.

[0028] (2) 50% of steel scrap: 10% of ferrosilicon: 40% of aluminum ingot. High-quality plate scrap steel is melted in an intermediate frequency furnace. After melting, ferrosilicon (75% Si content) is added for deoxidation and alloying, and then aluminum ingots are added, and the temperature is controlled at 1250°C. After the aluminum ingot is melted, the rare earth aluminum-calcium master alloy obtained in the first step is added, and the ingredients are uniformly mixed for 10 minutes, and the temperature of the alloy out of the furnace is controlled at 1100°C. It is cast into an allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com