Ultrahigh strength die steel with good corrosion resistance and toughness

An ultra-high-strength and corrosion-resistant technology, applied in the field of metallurgy, which can solve the problems of narrow material plate width, high price, and long steel plate delivery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

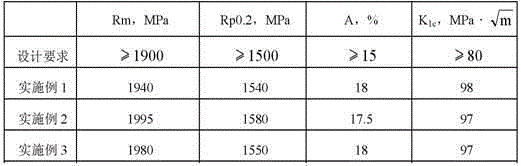

Examples

Embodiment Construction

[0016] The chemical composition (wt.%) of embodiment 1-3 invention steel

[0017] Example C Si mn Cr Ni W V Nb N co Mo O 1 0.08 0.03 0.02 12.30 5.00 0.90 0.20 0.08 0.0015 1.30 0.9 0.0012 2 0.20 0.50 0.01 10.05 8.00 1.00 0.30 0.10 0.0014 1.50 1.10 0.0011 3 0.32 0.80 0.05 11.13 10.1 1.10 0.50 0.15 0.0019 1.80 1.40 0.0014

[0018] 1) Vacuum induction furnace smelting; 2) Casting electrodes; 3) Vacuum consumable furnace remelting; 4) High temperature uniform diffusion; 5) Forging into materials; 6) Solution treatment; 7) Annealing treatment; 8) Double aging treatment The smelting steps include: smelting in an ultra-high-power electric furnace, selecting high-quality steel types, loading elements other than Cr and Ni into the crucible, preheating the crucible to 400-600°C, and evacuating to ≤ 2.7Pa, using 5 Melt at a melting rate of ~10kg / min. After complete melting, refine at a tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com