High-tenacity wear-resisting overlaying alloy welding wire for cold-rolling support roller

An alloy welding wire, high wear resistance technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problem of difficult to guarantee toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

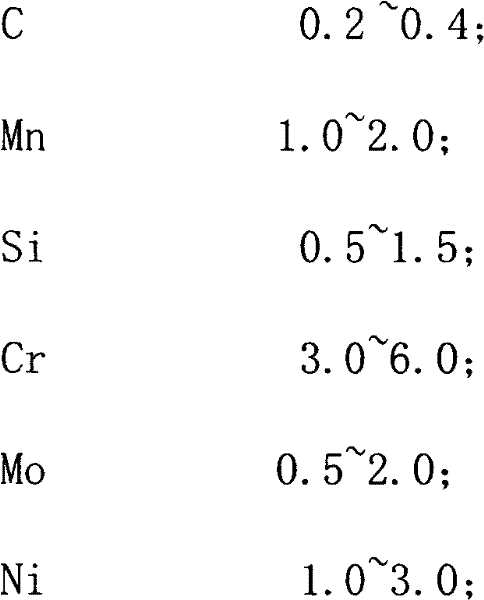

[0007] The invention uses a low carbon steel strip, rolls it into a tube, and fills the tube with impurities and additives. Impurities are minerals and alloy powders. The weight percentage of the chemical composition of the alloy wire powder is C: 0.2-0.4; Mn: 1.0-2.0; Si: 0.5-1.5; Cr: 3.0-6.0; Mo: 0.5-2.0; Ni: 1.0-3.0; ; S ≤ 0.01; wire alloy content of 6 to 12%. Impurities include one or several minerals such as CaF2, CaCO3, Na3SiF6, and LiF2, with a content of 2-5%; one or several of vanadium, tungsten, niobium, titanium, aluminum and other elements, with a total content of 0.3-2.0% A small amount of rare earth is added in it, the content is 0.1-0.5%, the powder is uniformly mixed in advance, and the particle size is 80-160 mesh. After adding the powder, the welding wire is combined with HJ107 flux, the current is 300-500 amps, the voltage is 30-35 volts, the speed is 350-600 mm / min, the interlayer temperature is 200-300 ° C, slow cooling after welding, and then passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com