A production process of ultra-low porosity and high densification abrasive

A production process and porosity technology, which is applied in the field of ultra-low porosity and high densification grinder production process, can solve problems such as hot cracks and metal inlays, and achieve the effects of improving wear resistance, reducing porosity and optimizing slag removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a production process for ultra-low porosity and high-densification abrasives, which specifically includes the following steps:

[0033] (1) Batching: batching is carried out according to the following formula, and the specific parameters are shown in Table 3, including the following components and parts by weight: 60 parts of iron powder, 8 parts of silicon carbide powder, 12 parts of steel fiber, 10 parts of lignin coupling agent, 10 parts of resin powder;

[0034] (2) Put the batch material into the vacuum mixer, pre-homogenize for 200 seconds, and then start granulation 15 seconds after adding the coupling agent. After 450 seconds of granulation, start vacuum granulation for 250 seconds. Mixture;

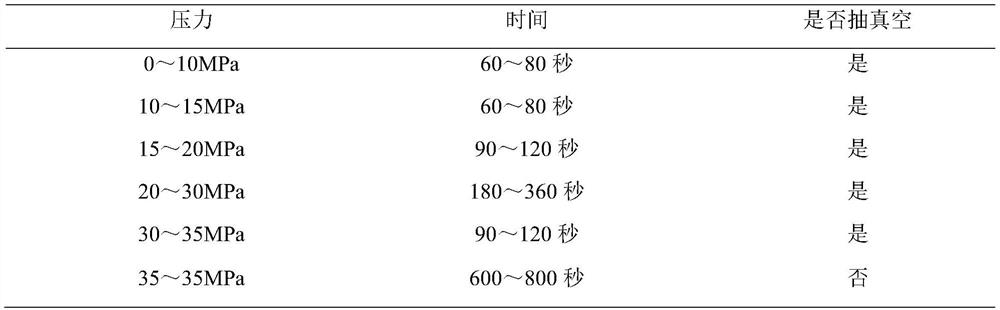

[0035] (3) Put the mixture into a vacuum hot press, put it into the matching steel back for vacuum pressing, the specific pressing process is: set the vacuum degree to 0.2MPa, after setting according to the pressing curve in Table 2, click Press ...

Embodiment 2

[0042] This embodiment provides a production process for ultra-low porosity and high-densification abrasives, which specifically includes the following steps:

[0043] (1) Batching: batching is carried out according to the following formula, and the specific parameters are shown in Table 3, including the following components and parts by weight: 55 parts of iron powder, 6 parts of silicon carbide powder, 13 parts of steel fiber, 9 parts of lignin coupling agent, 5 parts resin powder;

[0044] (2) Put the batch material into the vacuum mixer, pre-homogenize for 300 seconds, then put in the coupling agent for 20 seconds, start granulation, after 500 seconds of granulation, start vacuum granulation for 200 seconds. Mixture;

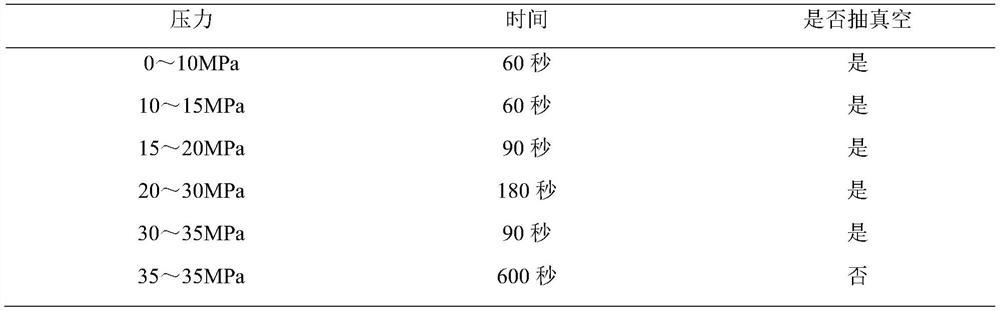

[0045] (3) Put the mixture into a vacuum hot press, put it into the supporting steel back for vacuum pressing, the specific pressing process is: set the vacuum degree to 0.1MPa, after setting according to the pressing curve in Table 3, click Press start butt...

Embodiment 3

[0052] This embodiment provides a production process for ultra-low porosity and high-densification abrasives, which specifically includes the following steps:

[0053] (1) Batching: batching is carried out according to the following formula, and the specific parameters are shown in Table 3, including the following components and parts by weight: 50 parts of iron powder, 7 parts of silicon carbide powder, 15 parts of steel fiber, 8 parts of lignin coupling agent, 10 parts of resin powder;

[0054] (2) Put the batch material into the vacuum mixer, pre-homogenize for 100 seconds, and then start granulation 10 seconds after adding the coupling agent. After 300 seconds of granulation, start vacuum granulation for 200 seconds. Mixture;

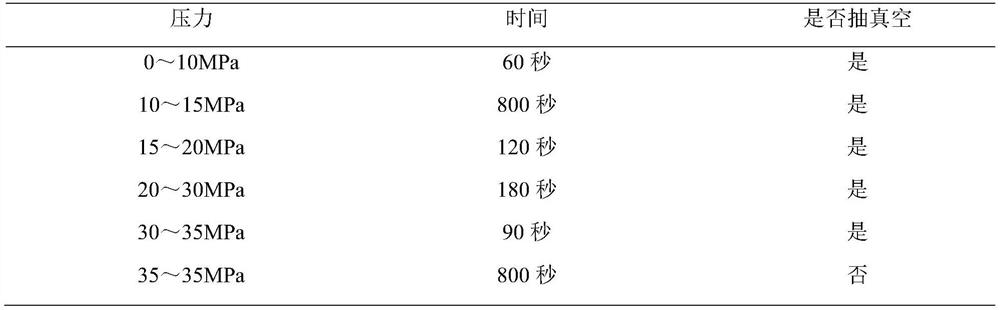

[0055] (3) Put the mixture into a vacuum hot press, put it into the supporting steel back for vacuum pressing, the specific pressing process is: set the vacuum degree to 0.3MPa, after setting according to the pressing curve in Table 4, click Press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com