Patents

Literature

57results about How to "Improve the densification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

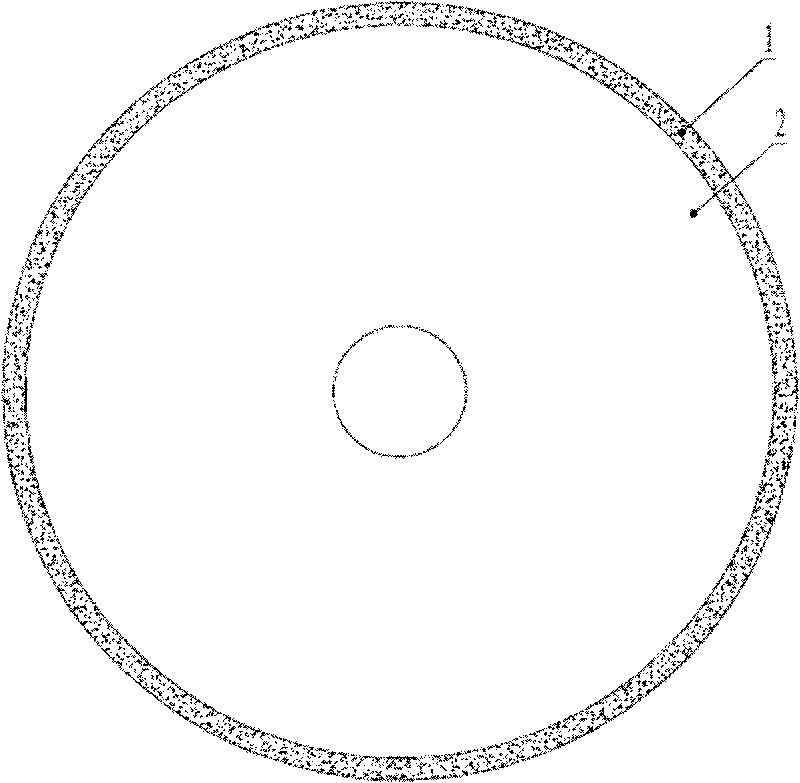

Marble cutting saw blade and preparation method thereof

ActiveCN101758560AFast cutting speedPromote infiltrationStone-like material working toolsAlloyPowder metallurgy

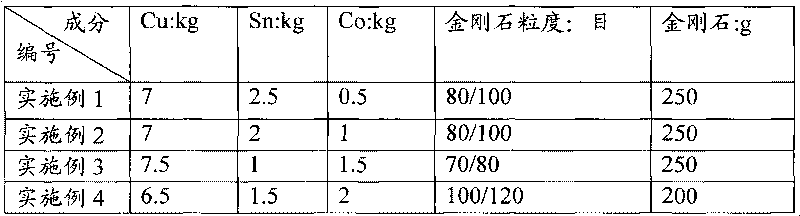

The invention relates to a super-hard tool and a preparation method thereof in the field of powder metallurgy, in particular to a marble cutting saw blade and a preparation method thereof. The saw blade comprises a matrix (1) and a tool bit (2), wherein the tool bit (2) is formed by mixing, thermally pressing and then sintering the matrix powder and the diamond particle; the component of the matrix powder includes 65 to 75 wt% of Cu, 10 to 20 wt% of Sn and 5 to 20 wt% of Co; and the weight of the diamond particle is 2 to 2.5 wt% of that of the matrix powder. The diamond saw blade is prepared after the steps of batching materials, mixing materials, cold press moulding, hot press moulding and subsequent treatment. Compared with the similar products, the Cu-base alloy diamond saw blade of the invention prolongs 1 to 3 times of the service life and reduces 30 to 50% of the cost on the premise of ensuring the constant sharpness and saw-cutting flatness.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

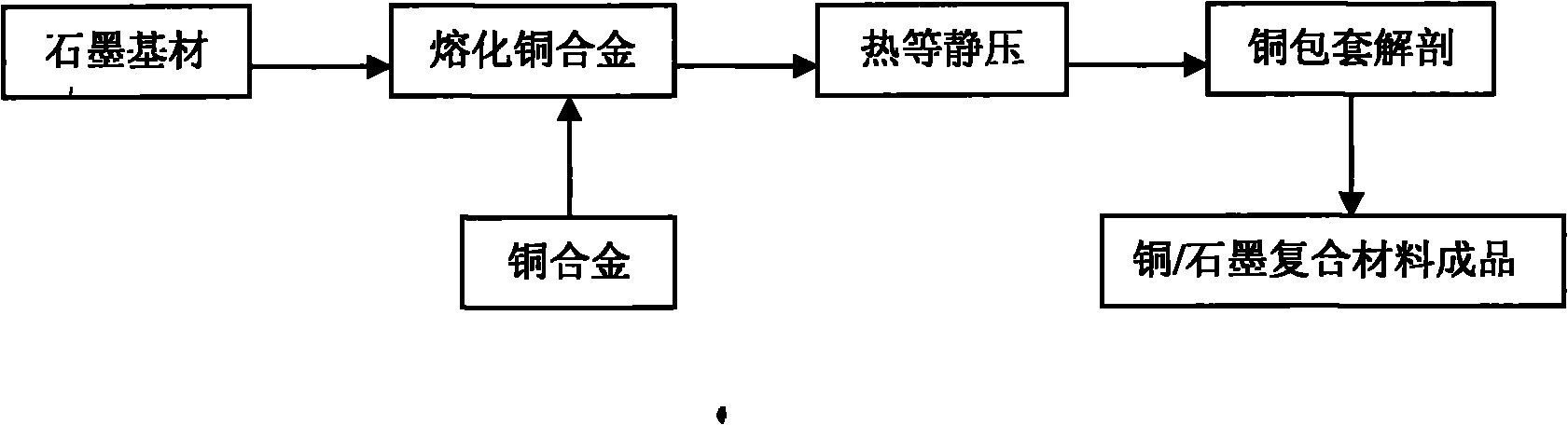

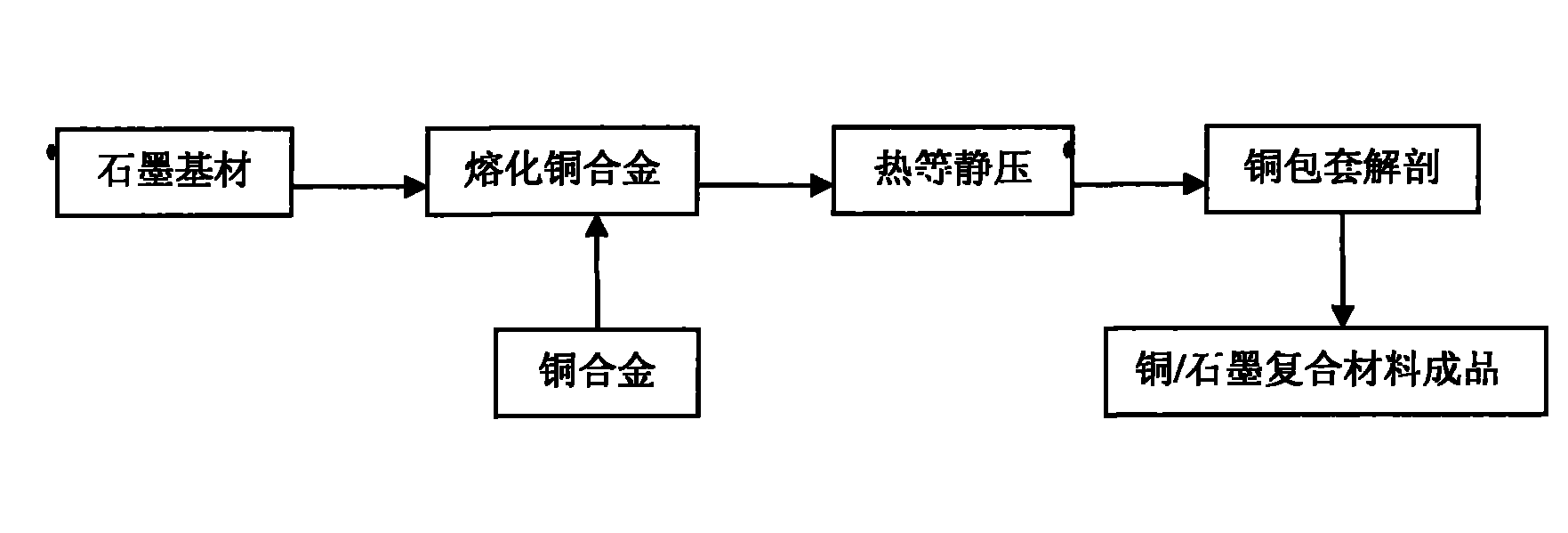

Copper/graphite compound material and preparation method thereof

ActiveCN102146552AHigh mechanical strengthIncreased mechanical toughnessHot-dipping/immersion processesThermal insulationCarbon graphite

The invention relates to a copper / graphite compound material and a preparation method thereof. In the compound material, carbon graphite is used as a substrate material, and a tin bronze alloy is used as a dipping metal. The preparation method comprises the following steps: (1) melting the tin bronze alloy to meltwater in a heat treatment furnace, immersing carbon graphite material blocks, and cooling so as to form a copper clad wrap coated by the graphite material blocks; (2) putting the copper clad wrap obtained in the step (1) in a hot isostatic press for hot isostatic press dipping at the temperature of 1100-1300 DEG C under the pressure of 60-80MPa at the atmosphere of argon, carrying out thermal insulation and pressure preservation for 60-120 minutes, and then carrying out belt pressure cooling; and (3) taking out the copper clad wrap obtained in the step (2) and then dissecting the copper clad wrap by using a machining method. The copper / graphite compound material is applied to machinery motive seal or bearings with high parameters (the temperature changes between minus 253 to 350 DEG C and the rotate speed is over 10000 rpm).

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

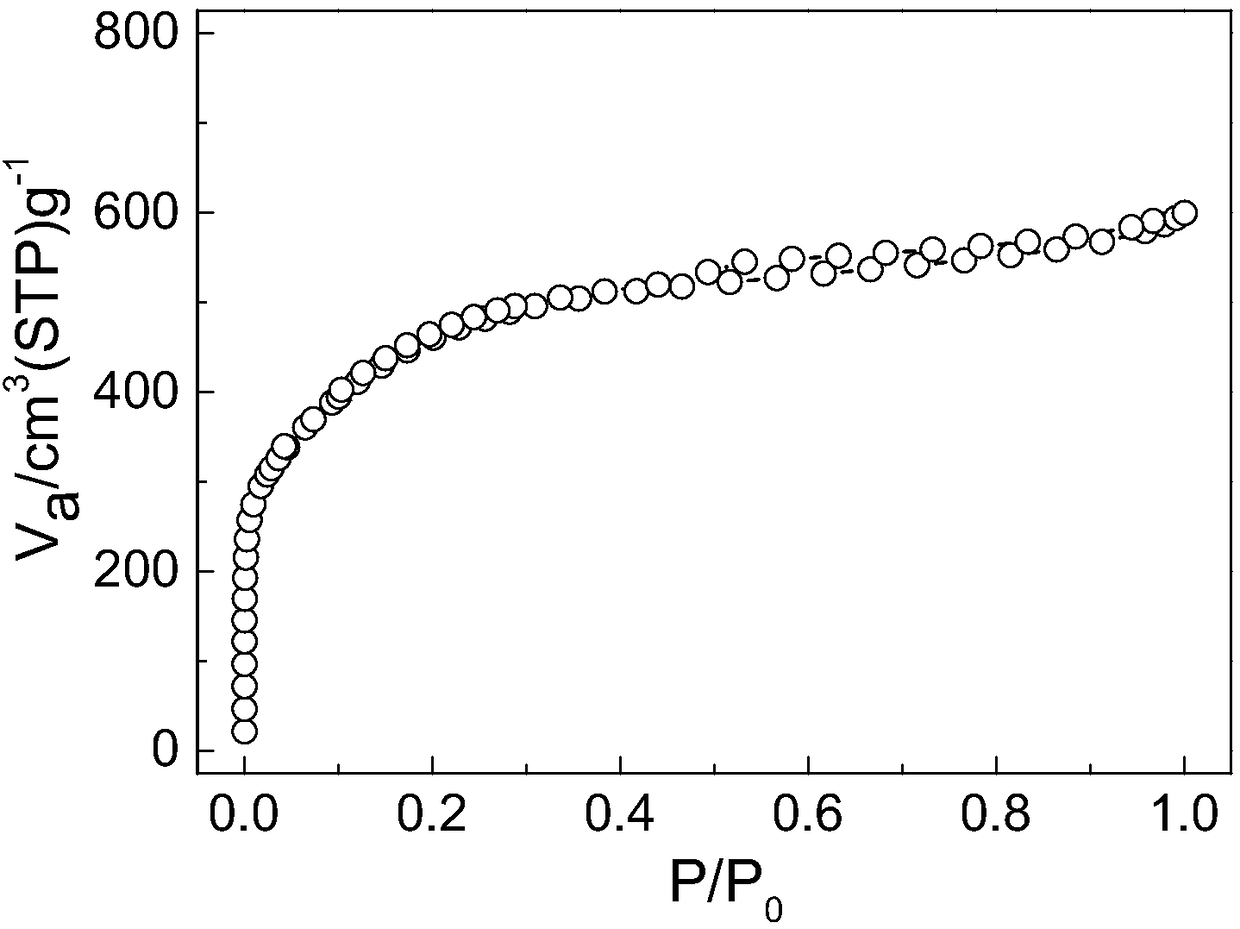

Preparation method of reinforced carbon-based composite material of carbon foam preform

A preparation method of reinforced carbon-based composite material of carbon foam preform includes the following steps: (1) stirring phenolic resin, surfactant, foaming agent and curing agent according to the mixture rate, namely the mass percent of 100:5:5:25, then adding chopped carbon fiber accounting for 3-15wt.% of the total weight to be mixed with the materials, and after uniform dispersion,putting the mixture in a baking oven that is preheated to 80-100 DEG C to be heated, foamed and solidified, thus obtaining phenolic foam with reinforced carbon fiber; (2) putting the phenolic foam with reinforced carbon fiber obtained in step (1) in a vacuum carbonization furnace, heating the phenolic foam to the temperature of 900-1, 000 DEG C at the heating rate of 10-20 DEG C / h under 1-2Pa lowvacuum and preserving the heat for 2-3h to obtain the carbon foam preform with reinforced carbon fiber; (3) under the temperature of 1, 000-1050 DEG C and the deposition pressure of 0.5-5kPa, takingnatural gas as a carbon source and nitrogen as carrier gas and adopting CVI technology to conduct compaction for 400-600h; and (4) conducting heat treatment on the material at the high temperature of2, 000-2, 300 for 3-5h after compaction treatment. The material has the advantages of light weight, high strength, low cost, corrosion resistance, resistance to wear, low coefficient of thermal expansion, etc.

Owner:BEIHANG UNIV

Production method of quartz composite ceramic radome with polytetrafluoroethylene damp-proof coating

ActiveCN107253853AExcellent high and low temperature stabilityReduce dosageRadiating element housingsLow-k dielectricVapor barrier

The invention relates to a production method of a quartz composite ceramic radome with polytetrafluoroethylene damp-proof coating; the production method comprises the steps of pretreating quartz fiber profiled fabric; impregnating the quartz fiber profiled fabric, combining, and drying; subjecting the quartz fiber profiled fabric base to vacuum impregnating, concentrating, performing integrated compositing, and drying; subjecting the base to high-temperature thermal treatment, and performing machining. A polytetrafluoroethylene coating layer is formed on the surface of the radome. The PTFE (polytetrafluoroethylene) film formed on the surface of the quartz ceramic, bringing good low dielectric constant, continuous high vapor barrier performance, excellent high and low temperature stability, and high weatherability, can provide ultralow damp-proof performance for the storage of radomes and antenna windows for missile weapon systems in severe environments.

Owner:湖北三江航天江北机械工程有限公司

Method for preparing proppant in high intensity

The present invention provides a preparation method of high-strength proppant. Said method includes the following steps: mixing bauxite raw ore powder, rare earth concentrate, combustible substance and binding agent according to a certain mixing ratio, grinding them into powder material, sphere-forming to obtain blank spheres, screen to obtain semi-finished product spheres, roasting at 1250-1500 deg.C, further screening, polishing, removing dust, finally covering the spheres with phenol-formaldehyde resin so as to obtain finished product. Said invention also provides its application range.

Owner:关昌烈 +1

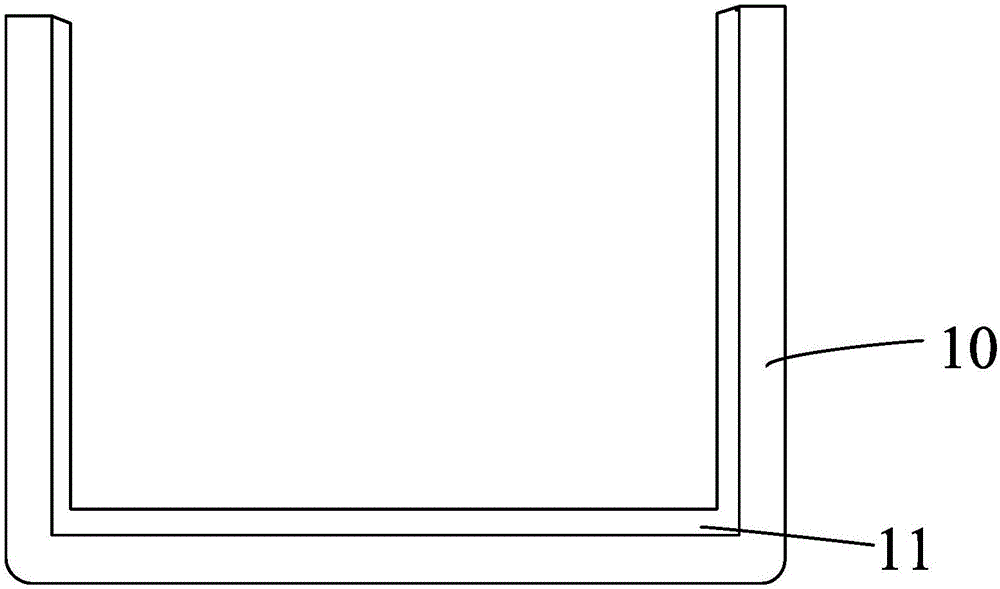

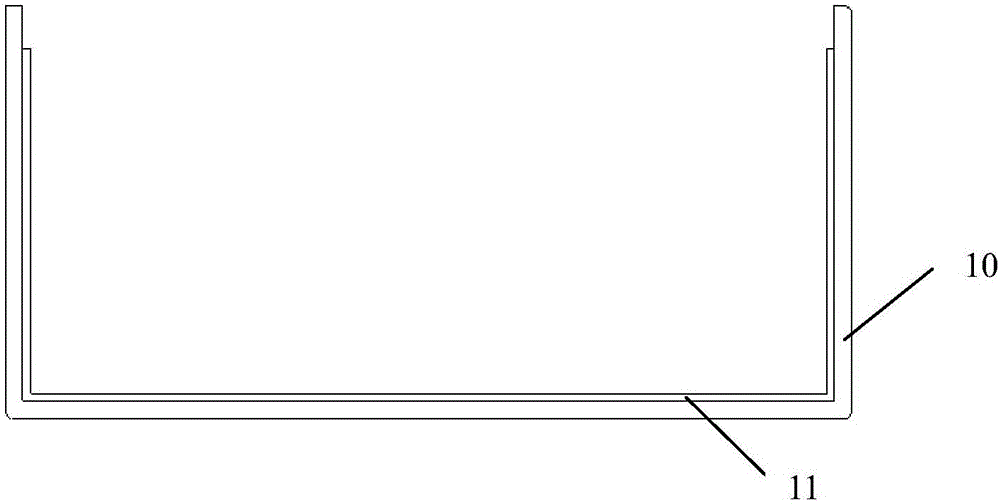

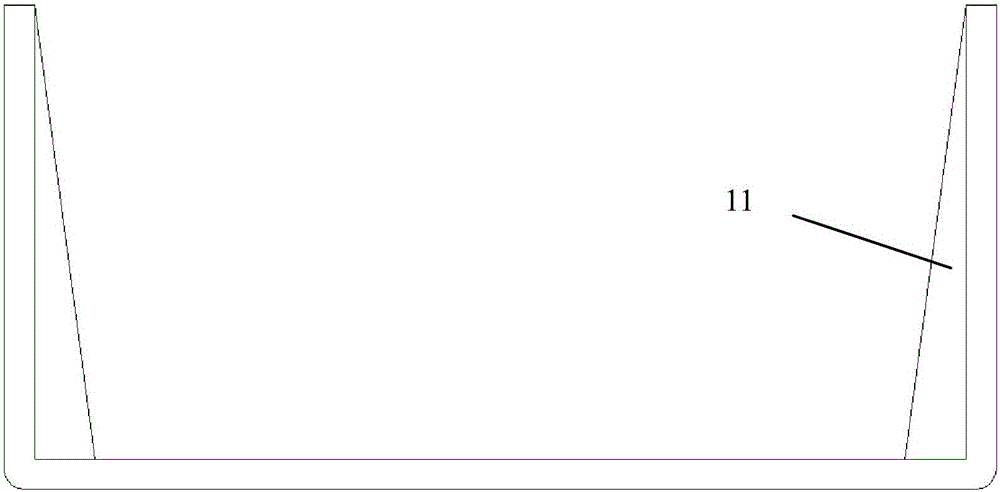

Quartz ceramic crucible for polycrystalline silicon ingot and preparation method thereof

ActiveCN106801252AGood barrier protectionImprove compactnessPolycrystalline material growthSingle crystal growth detailsHigh densityAdhesive

The invention provides a quartz ceramic crucible for a polycrystalline silicon ingot. The quartz ceramic crucible comprises a crucible body, wherein the crucible body comprises a base and a side wall extending upward from the base, wherein a high-purity quartz coating is arranged on the inner surface of the inner surface and / or side wall of the base; and the material of the high-purity quartz coating comprises fused quartz, low-temperature quartz, silicon nitride and silicon in a mass ratio of 1:(0.1-2):(0-0.5):(0-0.5), 0-1000ppm of barium hydroxide and zirconium oxide by mass and less than or equal to 25% of adhesive by mass. In the crucible, the inner surface of the crucible body is coated with a high-purity quartz coating which is finally transformed into a high-density coating in an ingot casting process, thus impurities in the crucible are effectively prevented from dispersing into the ingot, red areas on the side and bottom of the ingot are reduced, overall ingot quality is improved, and the crucible preparation cost is lowered. The invention also provides a preparation method of the quartz ceramic crucible for a polycrystalline silicon ingot.

Owner:江西中材新材料有限公司 +2

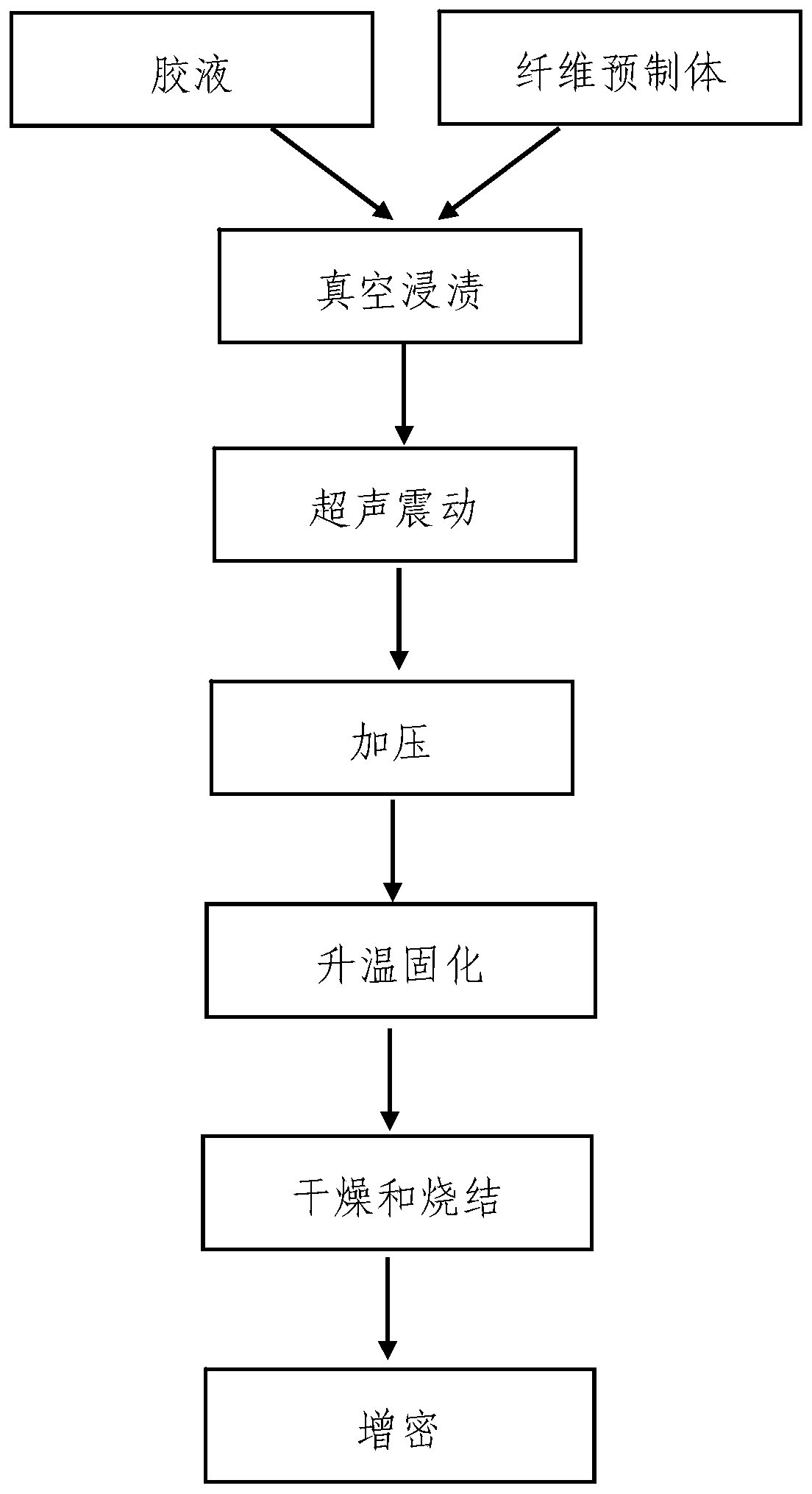

Fiber-reinforced ceramic matrix composite material, preparation method and application thereof

The invention relates to a fiber-reinforced ceramic matrix composite material, a preparation method and application thereof. The preparation method includes: (1) a step of preparation of a glue solution for impregnating a fiber preform; (2) a step of vacuum impregnation; (3) a step of curing; (4) a step of drying and sintering, and (5) a step of densification. Between the step (2) and the step (3), the method also includes the steps of: (i) carrying out ultrasonic vibration on a system containing the fiber preform and the glue solution for impregnation at the end of vacuum impregnation; and (ii) introducing compressed gas into the environment where the system is located at the end of ultrasonic vibration for pressurization, making the pressure of the environment where the system is locatedreach 1-4MPa, and keeping the maintaining time at 1-24h. The preparation method provided by the invention can prepare the fiber-reinforced ceramic matrix composite material which has thickness of 50mm or more and still has high density, excellent tensile strength and interlaminar shear strength.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

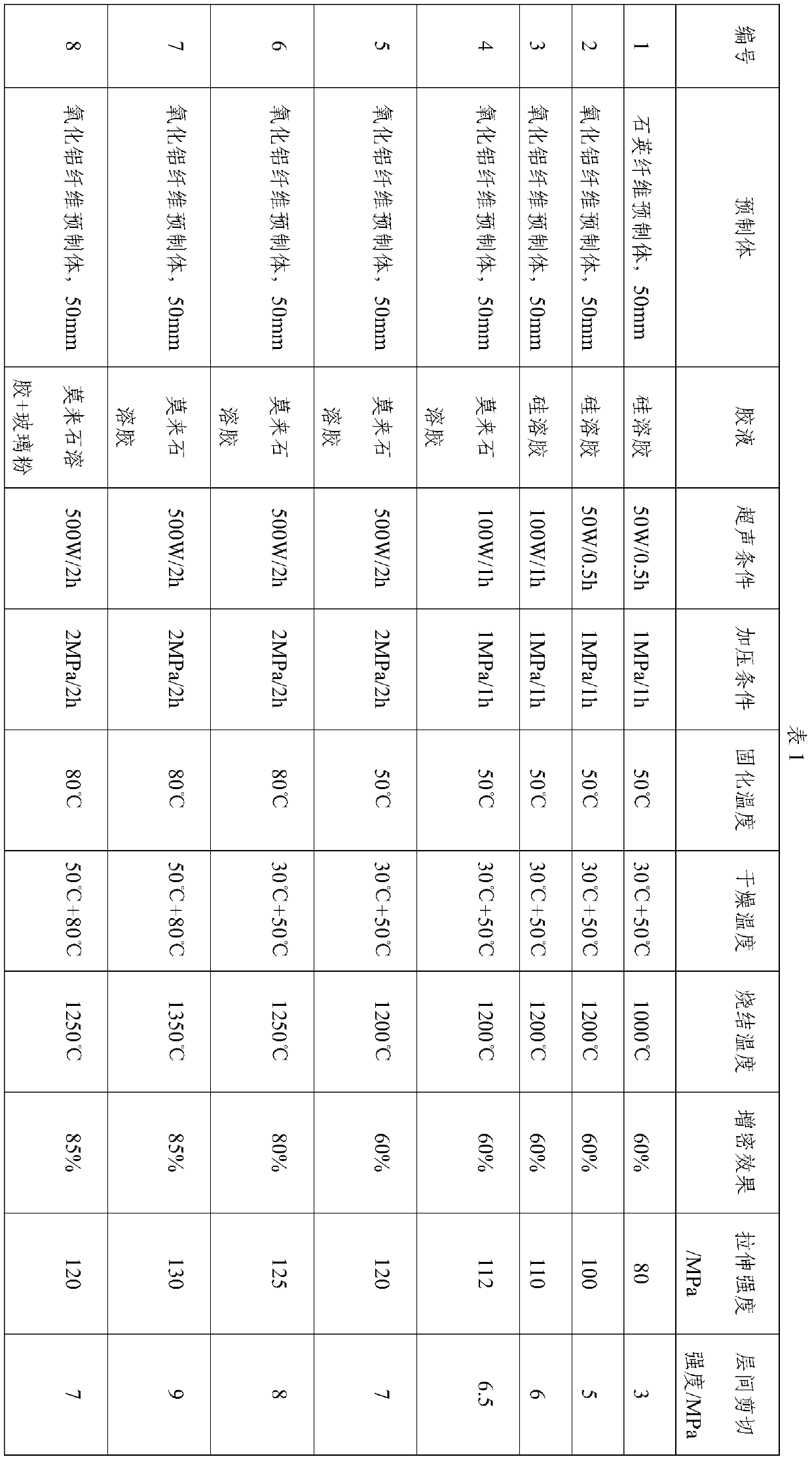

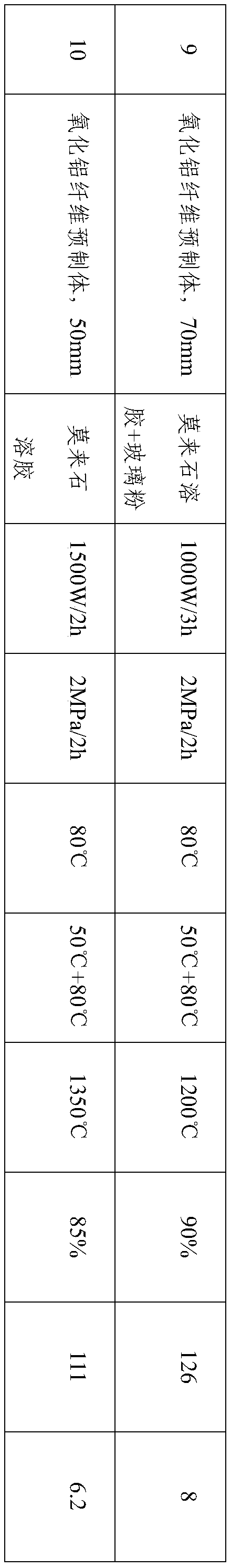

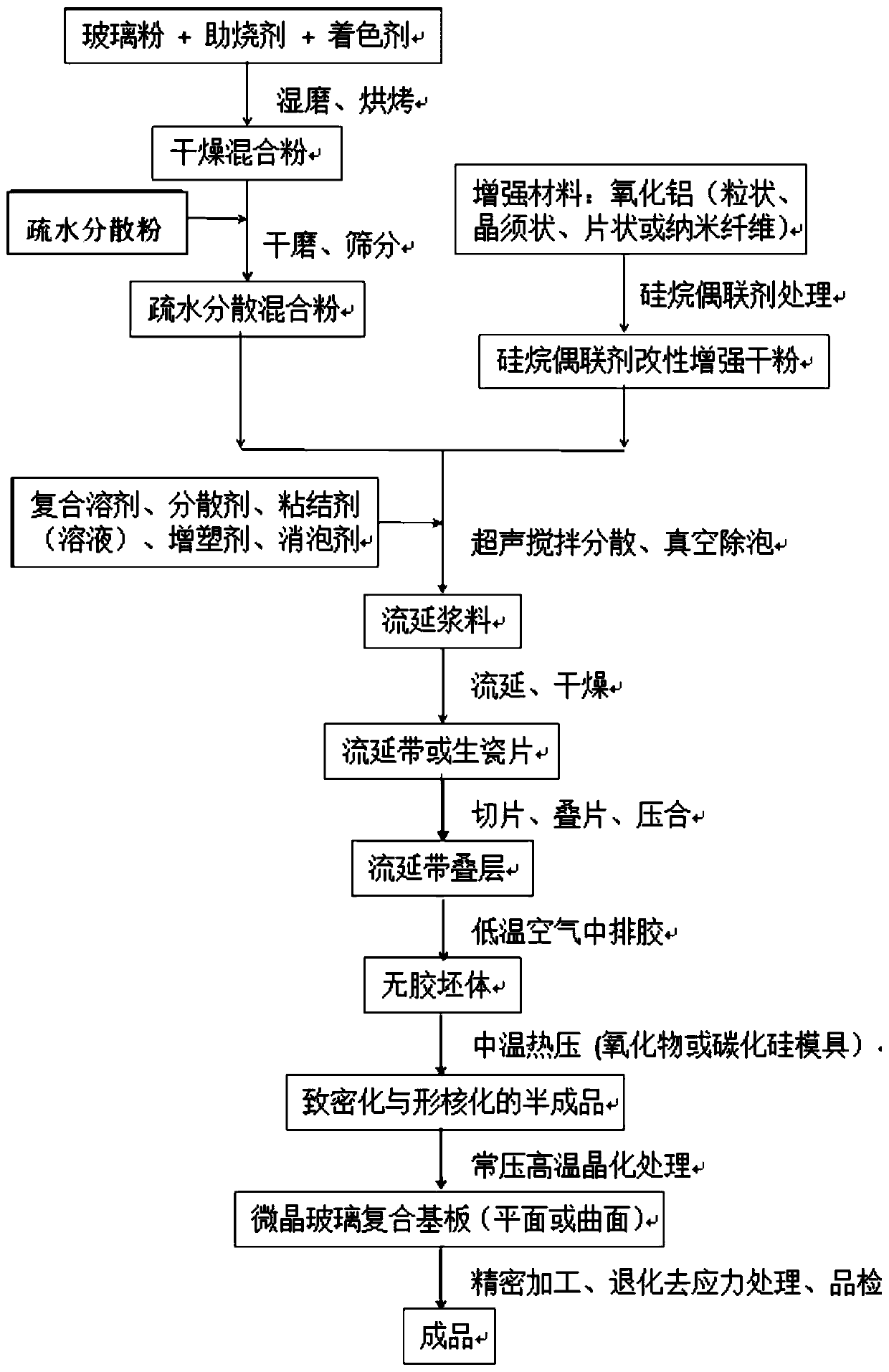

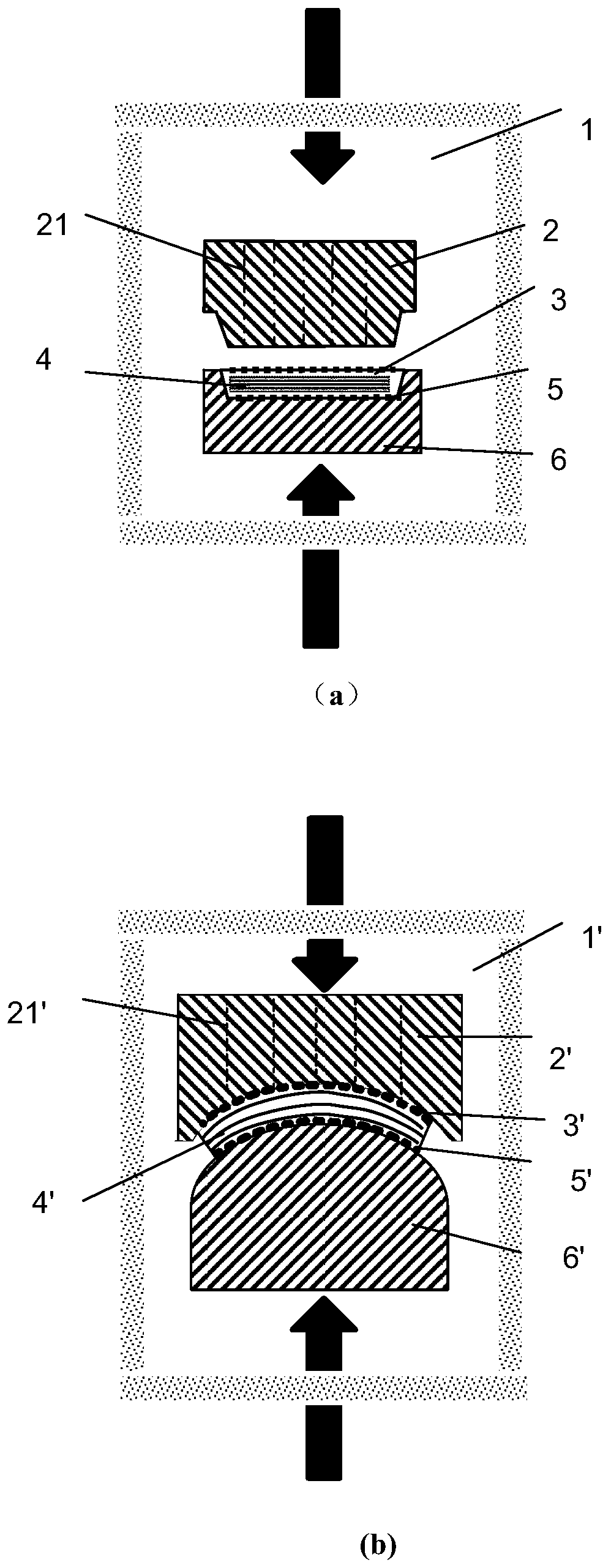

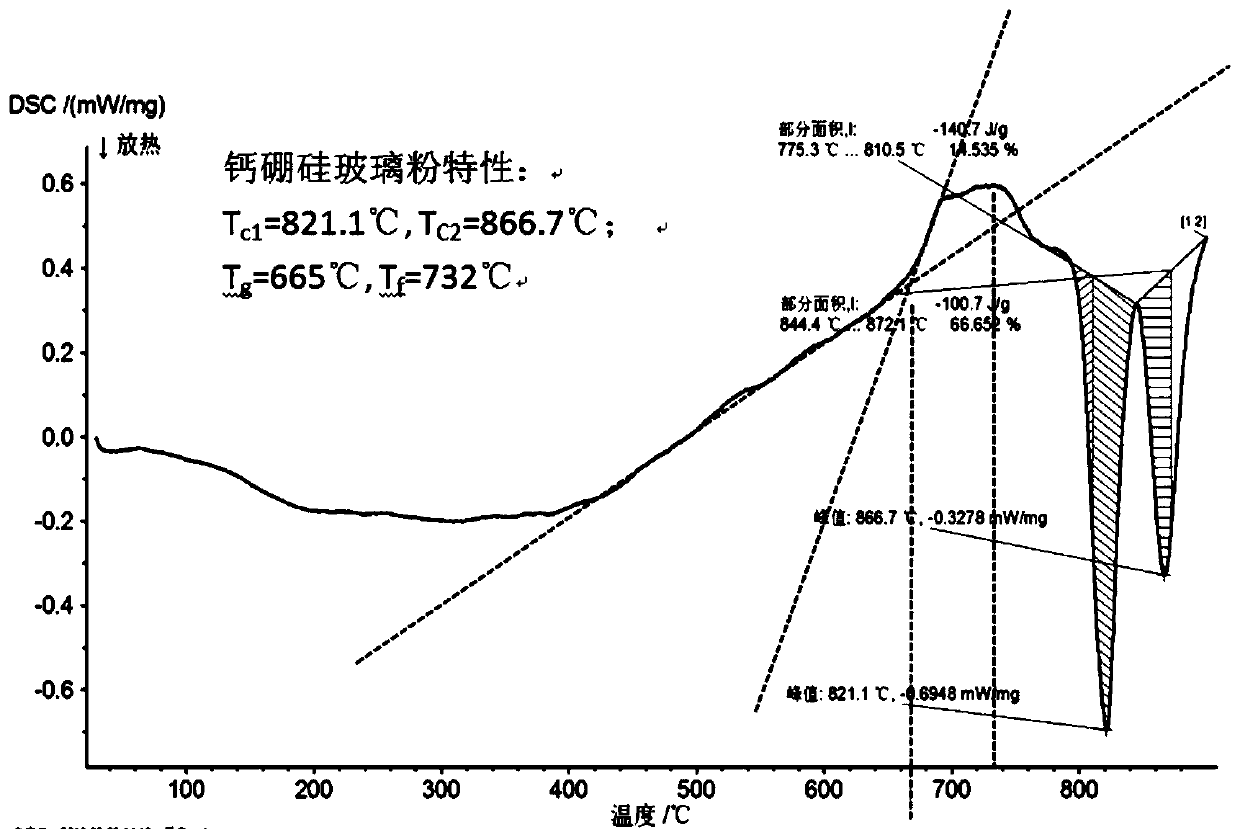

Reinforced calcium borosilicate microcrystalline glass composite material and preparation method thereof

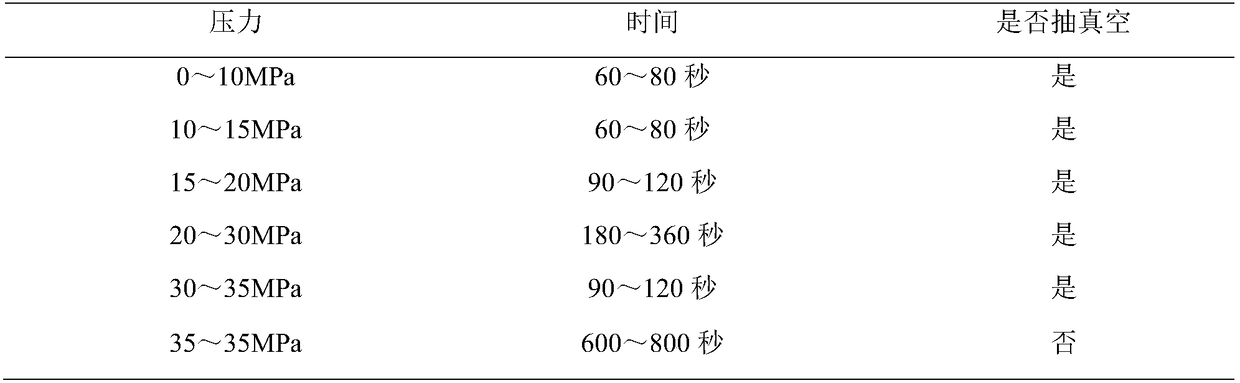

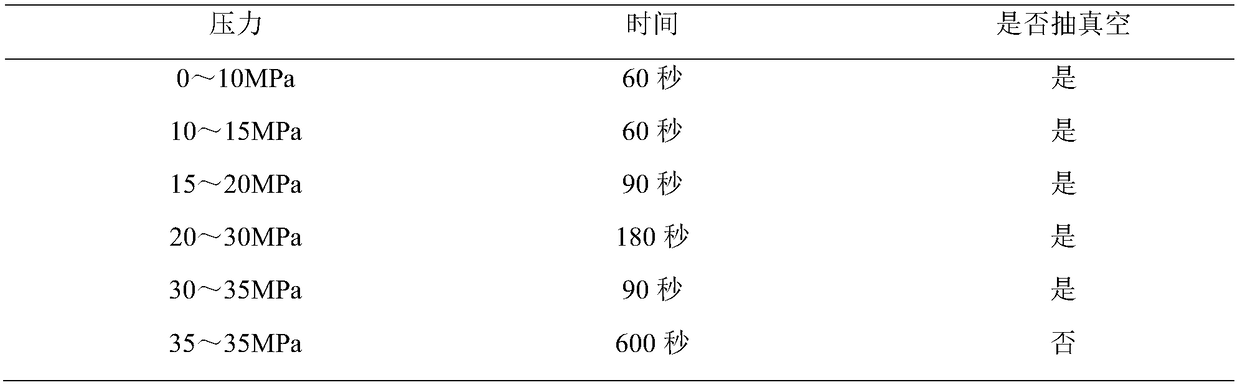

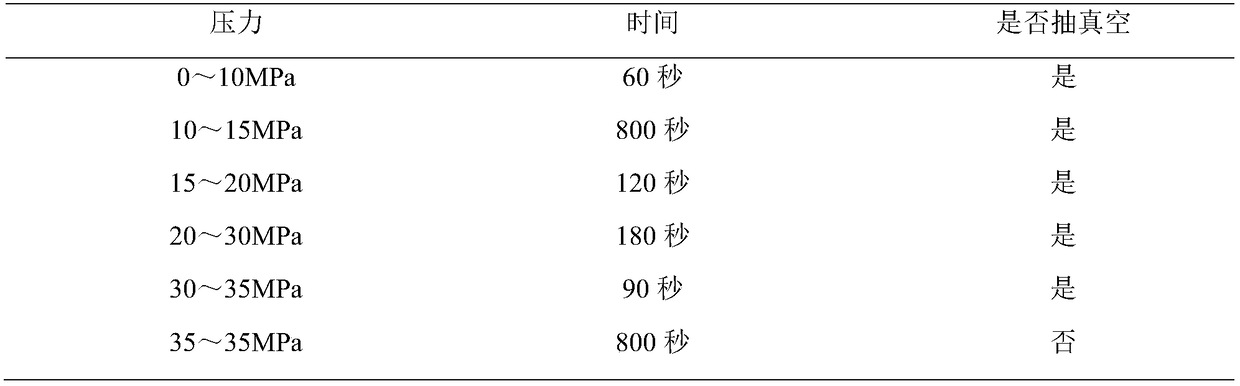

ActiveCN110683769AReduce lossImprove the densification effectGlass shaping apparatusFiberGlass composites

The invention discloses a reinforced calcium borosilicate microcrystalline glass composite material and a preparation method thereof. The reinforced calcium borosilicate microcrystalline glass composite material contains a matrix composed of glass powder, a sintering aid and a colorant, and an alumina reinforced phase (composite powder) with the volume percentage of 5-35%. The glass powder is prepared from the following specific components in percentage by mass: 35 to 50% of CaO, 10 to 25% of B2O3, 35 to 50%t of SiO2, 0.1 to 1.5% of Al2O3, 0.1 to 1.5% of MgO and 0.1 to 2.5% of ZrO2. The glasspowder is mixed with 0.5-3.5% by mass of an external dopant (i.e., a compound of the sintering aid and the colorant); wherein the composite sintering aid is an xV<2>O<5>-yTeO<2>-z3Li<2>O*2B<2>O<3> composition, the colorant is any one or a combination of more than one of Cr2O3, Co2O3, CuO and MnO2, and the mass percentage content of the colorant accounts for 0-1.5%. According to the invention, sheet-shaped, whisker-shaped or short-fiber-shaped aluminum oxide with good reinforcing and toughening effects is utilized, and a staged hot-pressing casting sheet lamination method is adopted to reinforce and toughen calcium borosilicate microcrystalline glass with good high-frequency dielectric properties, so that a composite material plane or curved substrate with high strength (more than 250MPa) and low loss (less than 0.001) is prepared.

Owner:赣州中傲新瓷科技有限公司

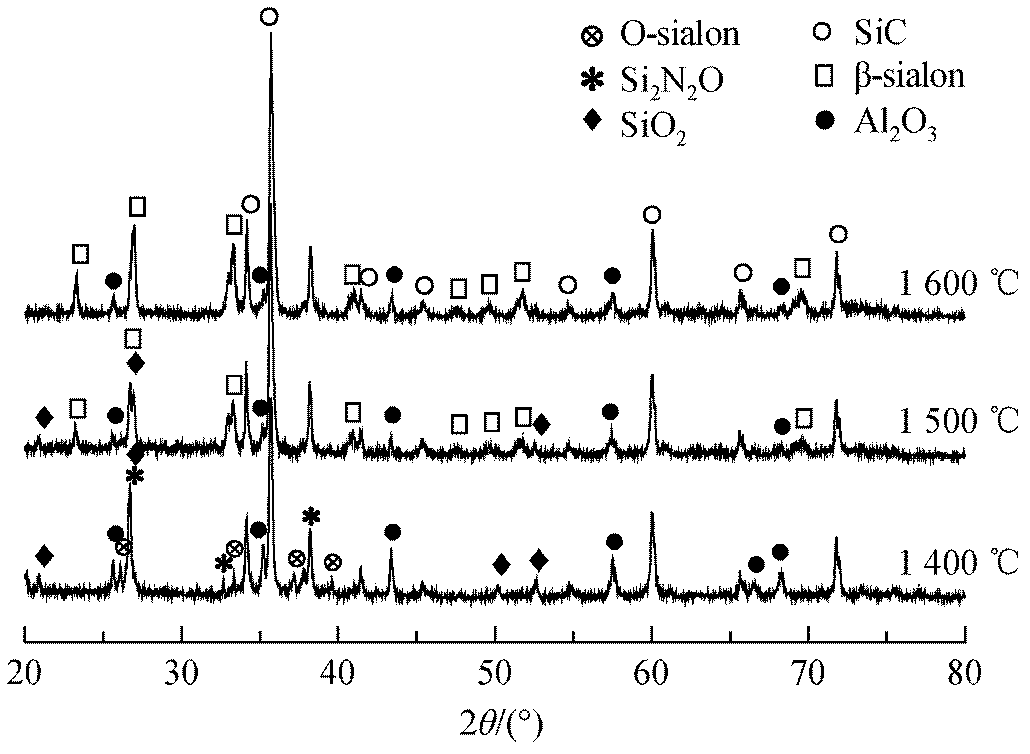

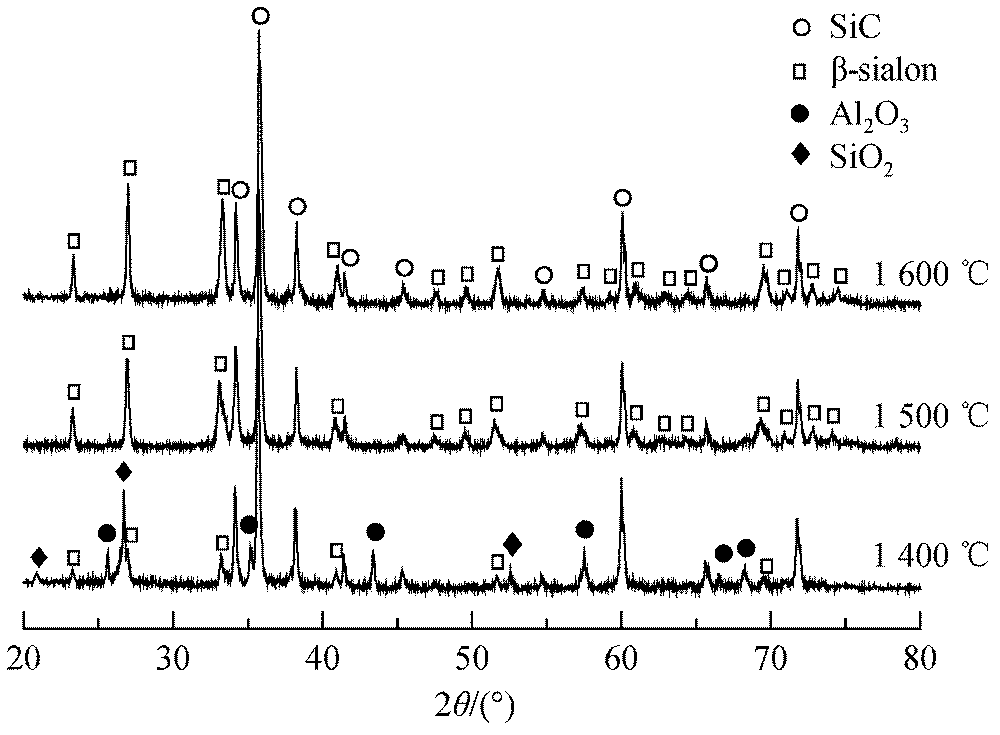

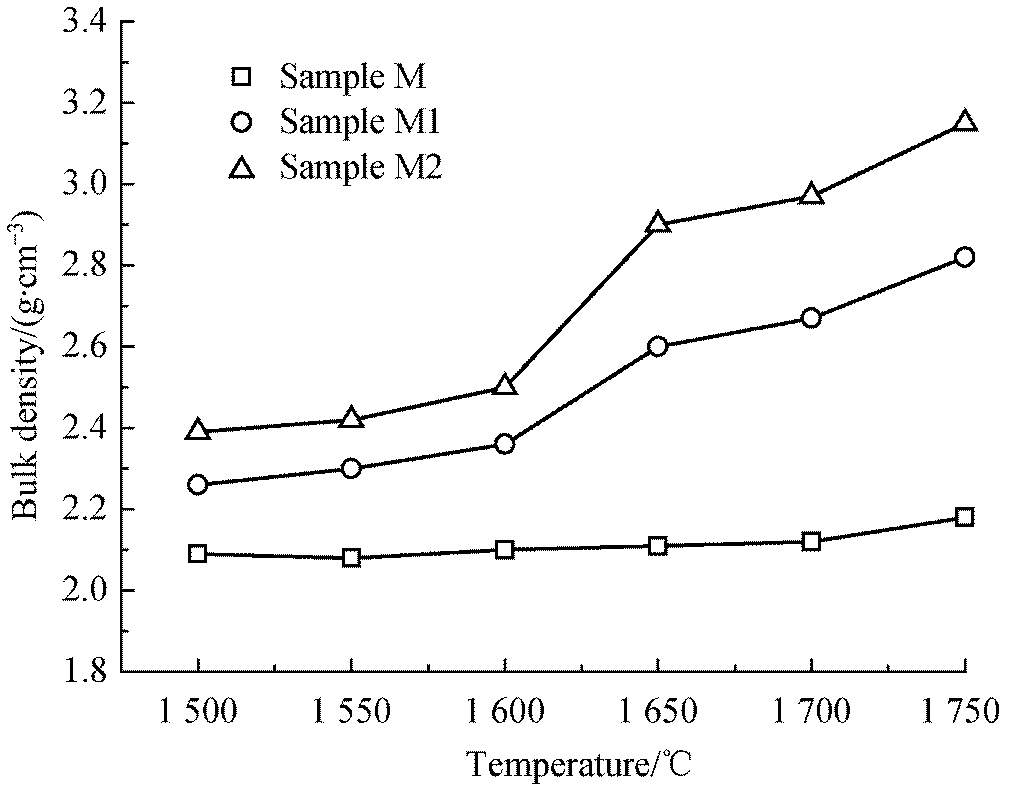

Multiphase ceramics material with low density and high strength and preparation method thereof

The invention discloses a multiphase ceramics material with low density and high strength and a preparation method thereof. The material has broad application range and is particularly suitable for the field of armor protection. The ceramics material is prepared by adopting SiC, Si powder, Al2O3, soochow soil and SiO2 as materials, and sintering with addition materials at the high temperature of 1400-1750 DEC C under the condition of flowing nitrogen. The soochow soil can be used for promoting the generation of a beta-sialon phase effective, and the addition materials can be used for promoting sintering densification of samples, so that the obtained ceramics material has the volume density being 75 percent of that of Al2O3 ceramics material, and the strength being improved by 40 percent compared with that of the Al2O3 ceramics material.

Owner:NANJING UNIV OF TECH

High-density non-magnetic steel counterweight part and manufacturing method thereof

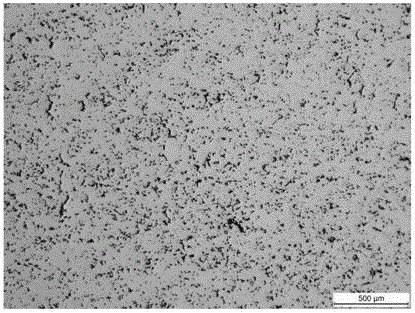

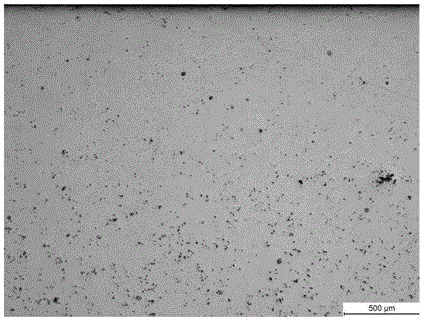

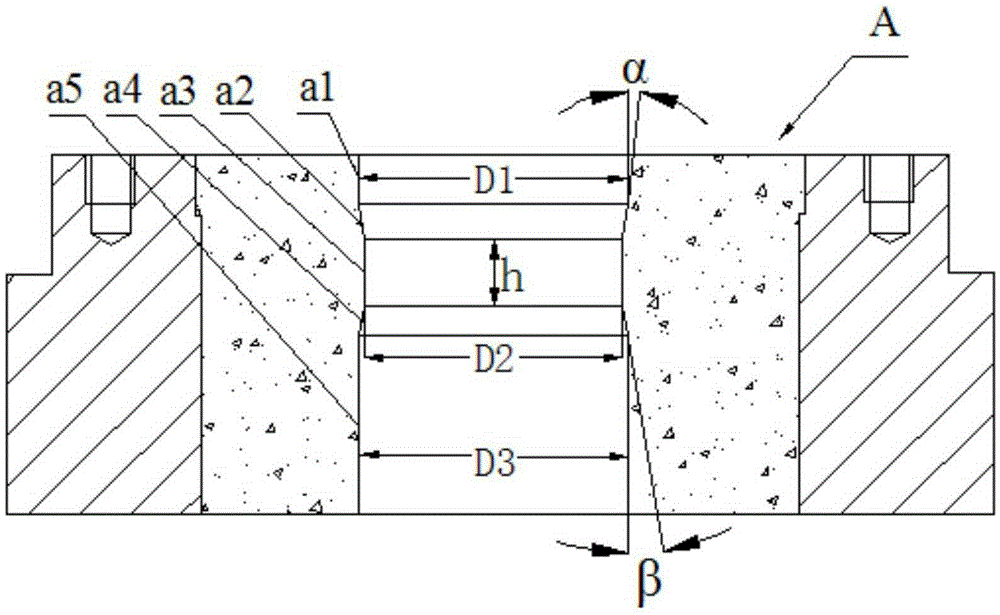

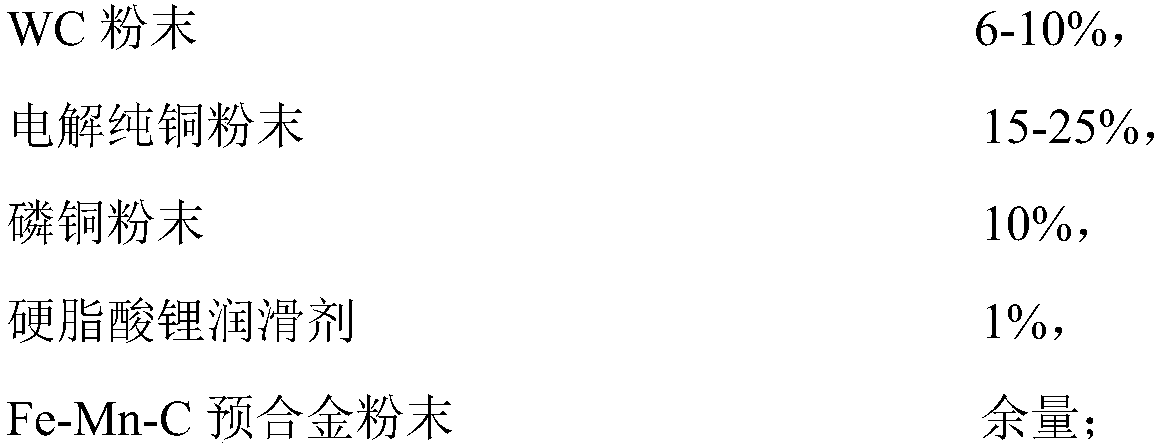

ActiveCN106544570ASolve the problem of poor compressionHigh strengthTransportation and packagingMetal-working apparatusElectrolysisHigh density

The invention discloses a high-density non-magnetic steel counterweight part and a manufacturing method of the high-density non-magnetic steel counterweight part. The high-density non-magnetic steel counterweight part comprises, by mass percentage, 6-10% of WC powder, 10% of phosphor copper powder, 15-25% of electrolytic pure copper powder, 1% of a stearic acid lithium lubricant and the balance Fe-Mn-C prealloyed powder. The manufacturing method of the high-density non-magnetic steel counterweight part includes the following steps that (1), the components are weighed according to the mass percentage and uniformly mixed in a mixing machine; (2), the mixed powder uniformly mixed is pressed and formed; and (3), high temperature sintering is performed. The manufacturing method is simple in process, controllable in cost, near-net formed and controllable in dimensional change, and the high-density non-magnetic steel counterweight part with the density of 7.7-7.9 g / cm<3> is manufactured.

Owner:GUANGDONG YUEHAI HUAJIN TECH CO LTD

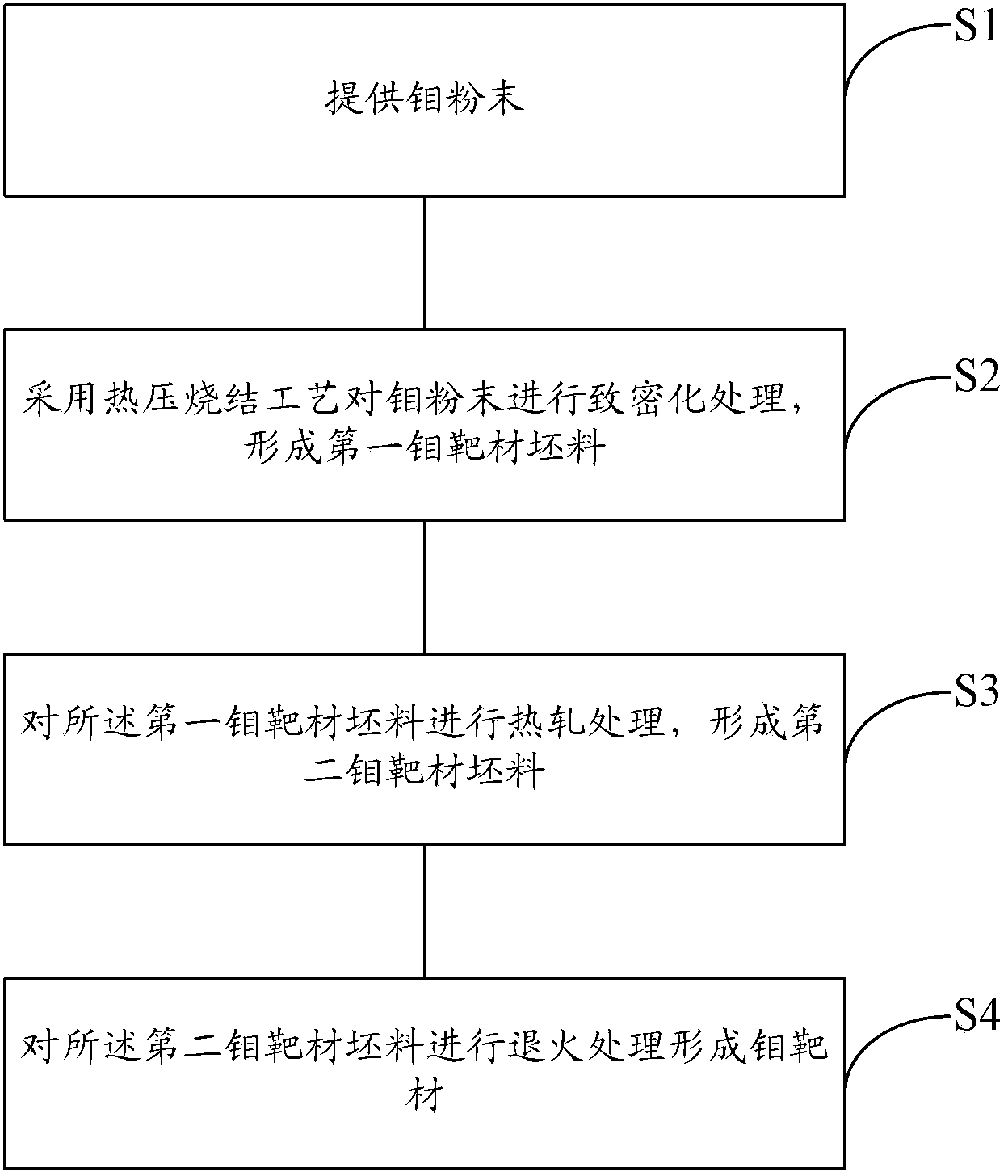

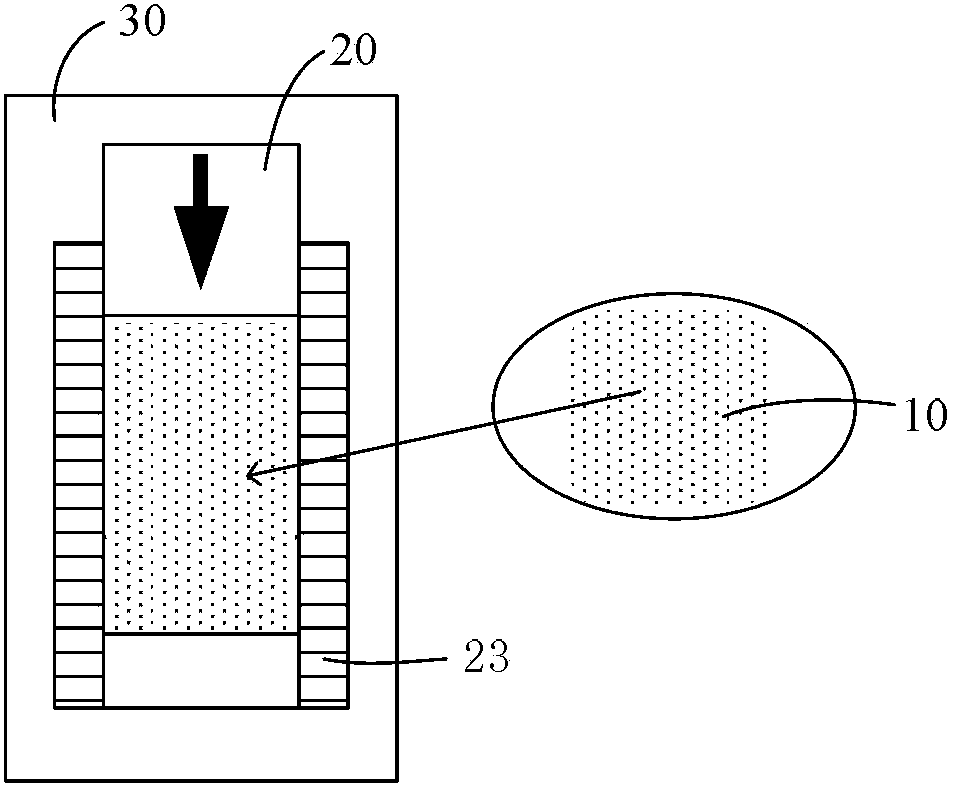

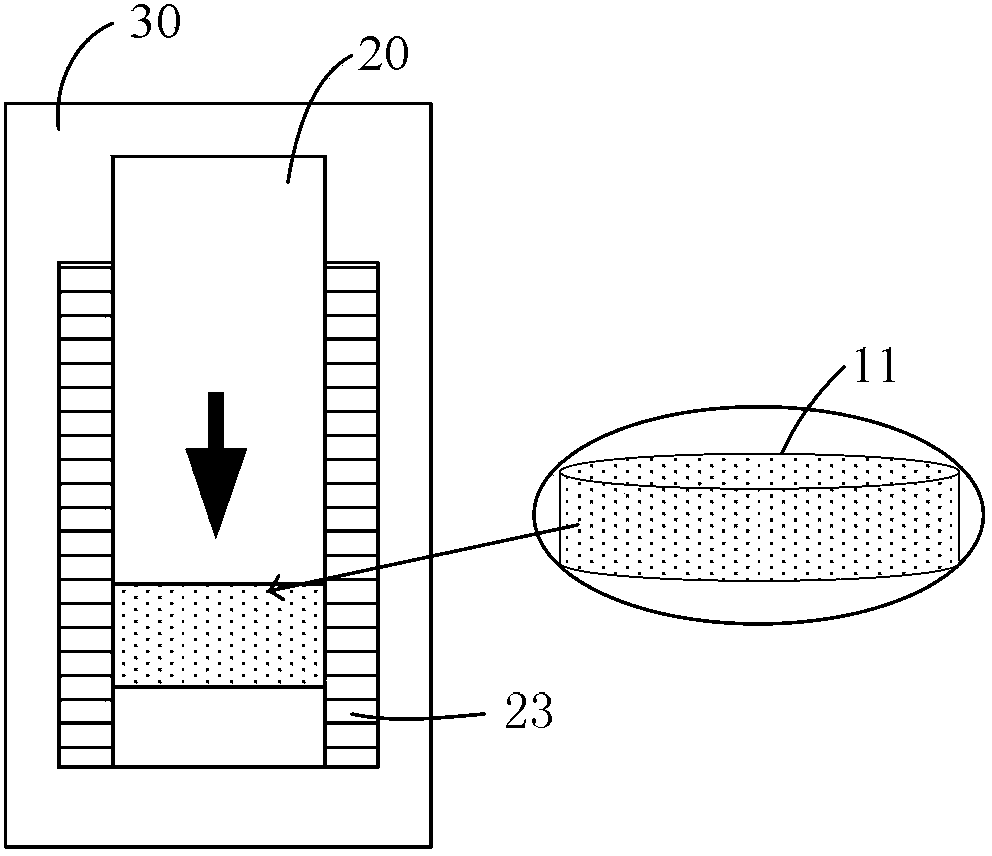

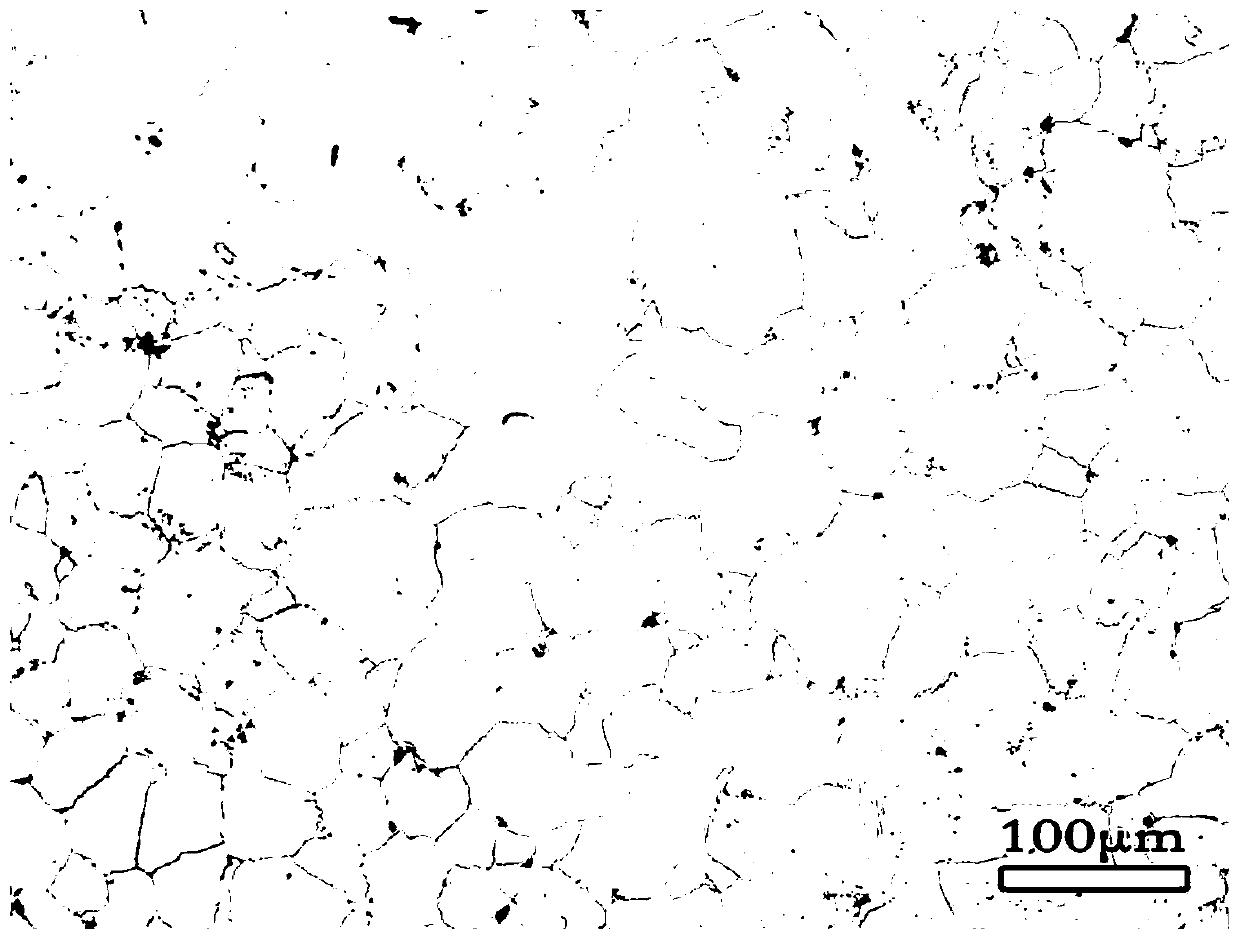

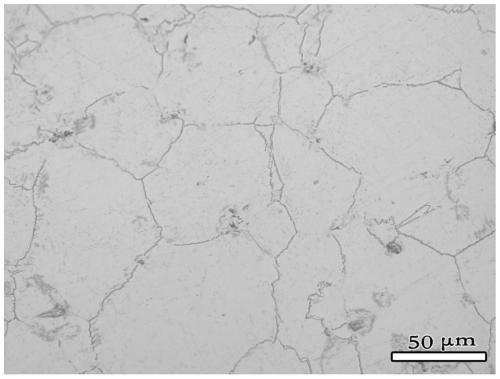

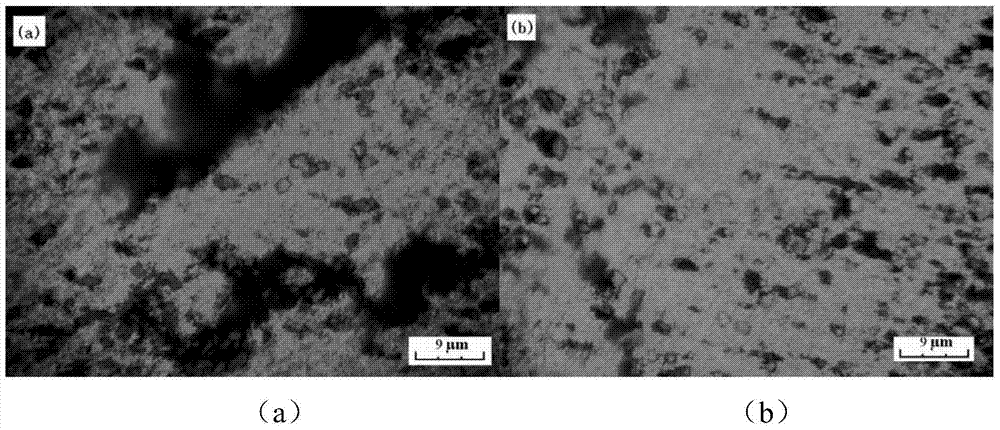

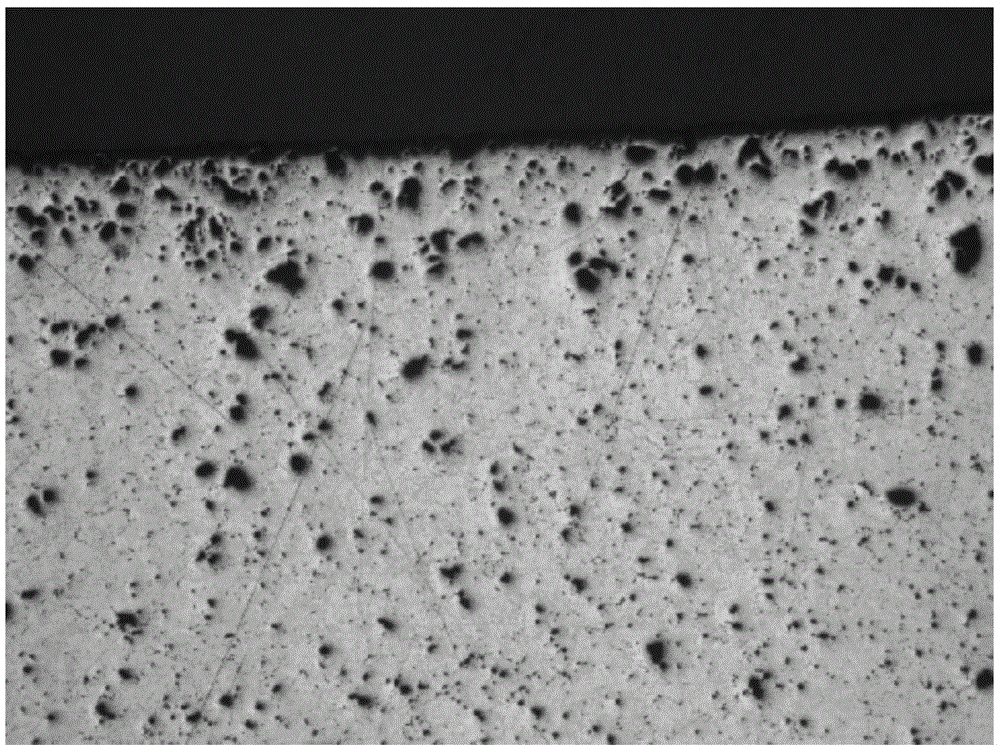

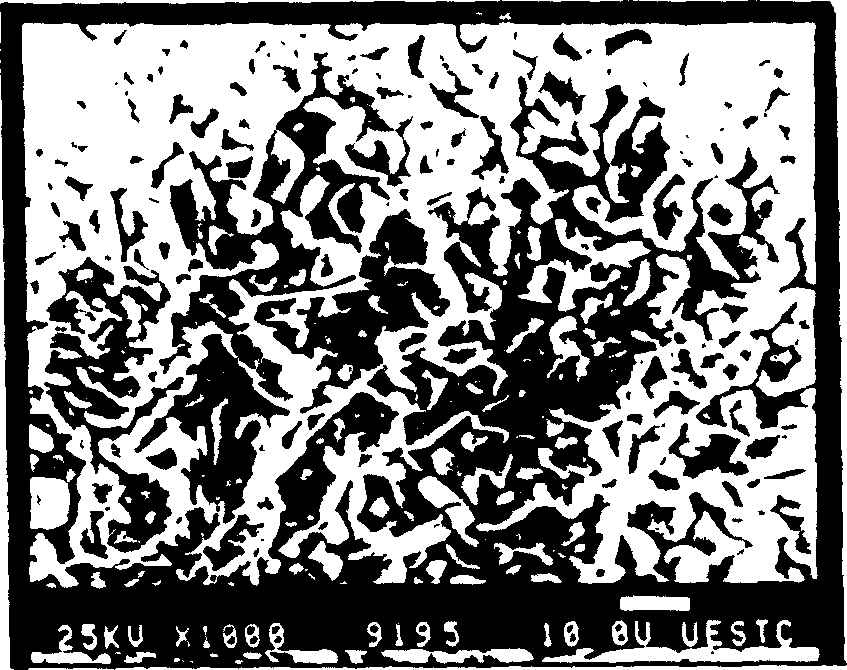

Method for manufacturing molybdenum target material

ActiveCN104342619AAchieving the first densificationIncreased dislocation densityVacuum evaporation coatingSputtering coatingSputteringMicrometer

A method for manufacturing a molybdenum target material comprises the steps that densification processing of molybdenum powder can be achieved through a hot pressed sintering technology; a first molybdenum target material blank can be obtained; further densification processing of the first molybdenum target material blank can be achieved gradually through a multi-stage hot rolling processing technology, and therefore the molybdenum target material with the molybdenum particle grain smaller than 50 micrometers, and the density higher than 99.94 percent can be obtained. Compared with a molybdenum target material obtained through a conventional molybdenum target material manufacturing method, the molybdenum target material obtained through the method is smaller and evener in molybdenum particle grain and high in density, has the better electrical properties and mechanical machining properties, and completely meets the molybdenum target material sputtering requirement.

Owner:广东江丰电子材料有限公司

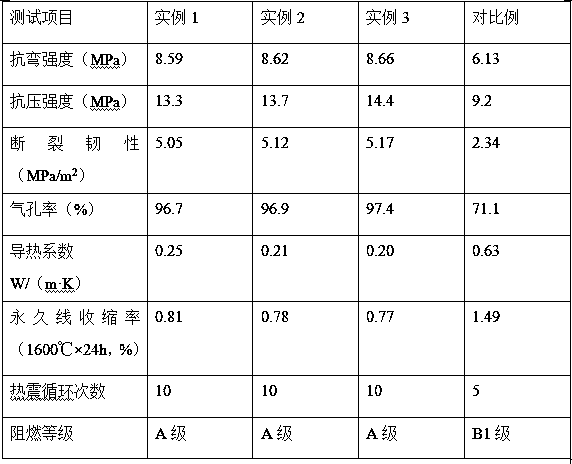

Preparation method of fiber enhanced thermal-shock-resisting foam ceramic

InactiveCN108863421AHigh closed cell rateLow thermal conductivityCeramicwareParaffin waxSilicon nitride

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Preparation method of energy-saving floor tile

InactiveCN108585872AImprove insulation effectImprove energy saving and temperature control performanceHeat-exchange elementsFlooringImpurityIndoor air

The invention discloses a preparation method of an energy-saving floor tile, and belongs to the technical field of preparation of building materials. After a prefabricating body of the floor tile is sintered, polyurethane is pyrolyzed to form a loose porous structure, and thermal phase change microcapsules in paraffin sol are distributed into the pore structure, and can be melted to absorb heat and store energy in summer, and cured to discharge heat and increase temperature in cold days, so as to reduce the electric utilization amount of temperature regulating devices of indoor air conditioners and the like. The energy-saving floor tile has the advantages that the liquid phase is mainly provided by silicon sol, and the amorphous silica in the silicon sol is firstly gelled and dewatered, then generates particle agglomeration in the temperature rising process, so that the powder flowing, dispersing and firing are accelerated, and also can react with other oxides in the substrate at hightemperature, the silicon carbide is oxidized at high temperature, an amorphous oxidizing layer is produced at the surface, the activity of the amorphous oxidizing layer is very high, and the amorphousoxidizing layer can react with impurities in the substrate to generate low-melting point phase for accelerating sintering, so that the sintering temperature of the floor tile is reduced, and the energy consumption in production of the floor tile is decreased; the application prospect is broad.

Owner:FOSHAN JIUBAI TECH INFORMATION CONSULTATION CO LTD

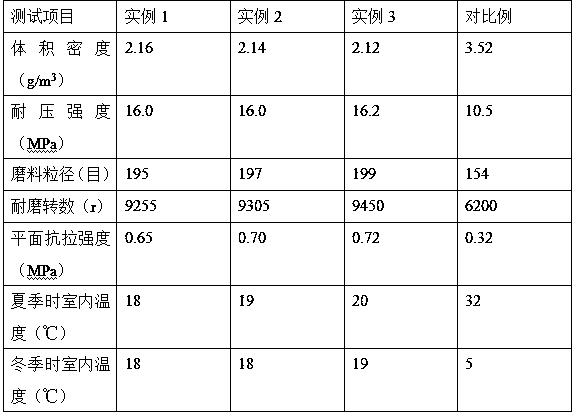

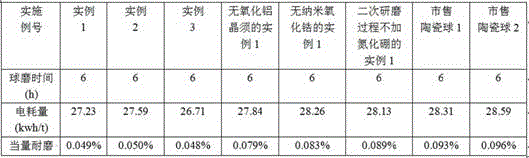

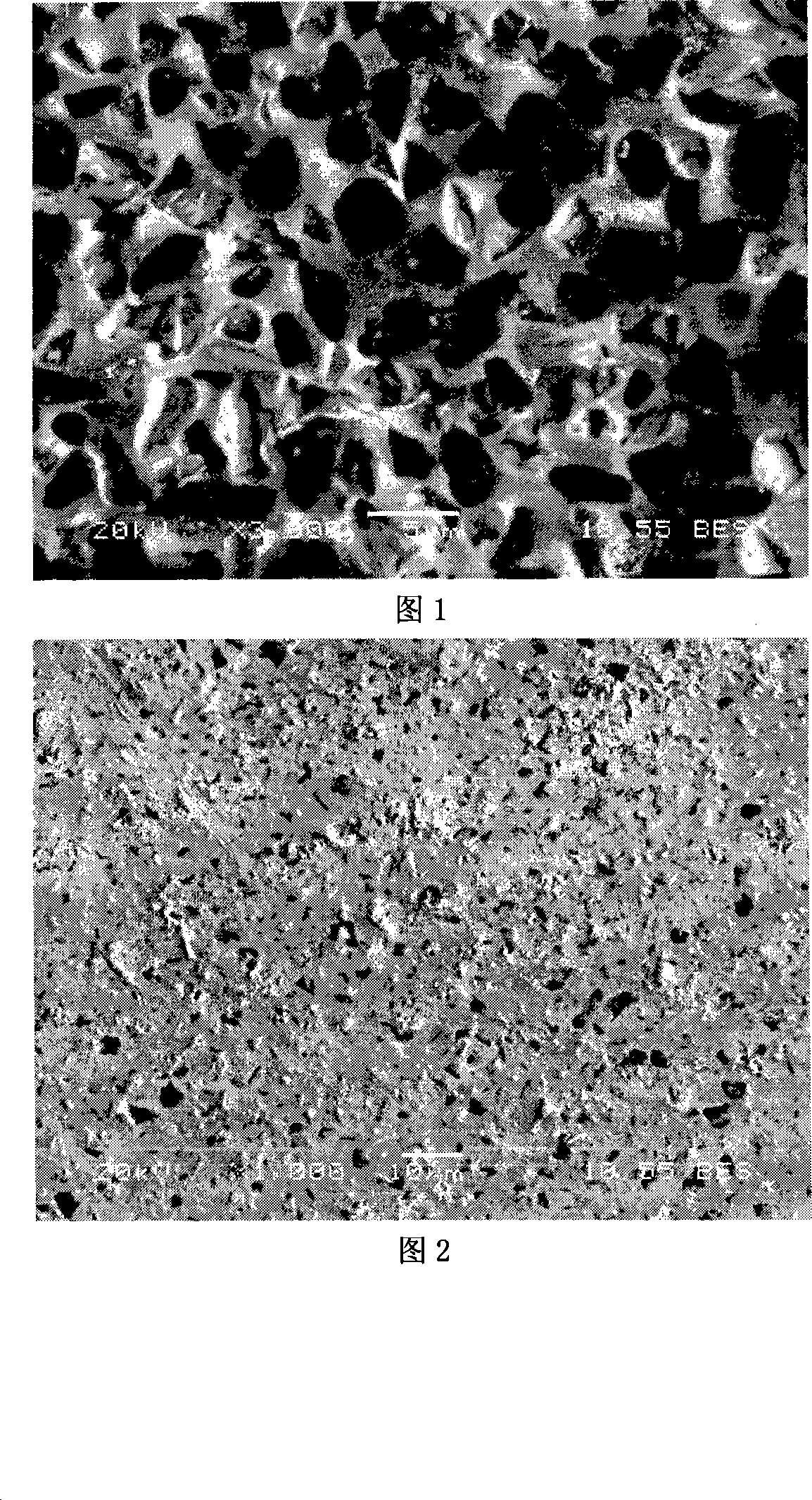

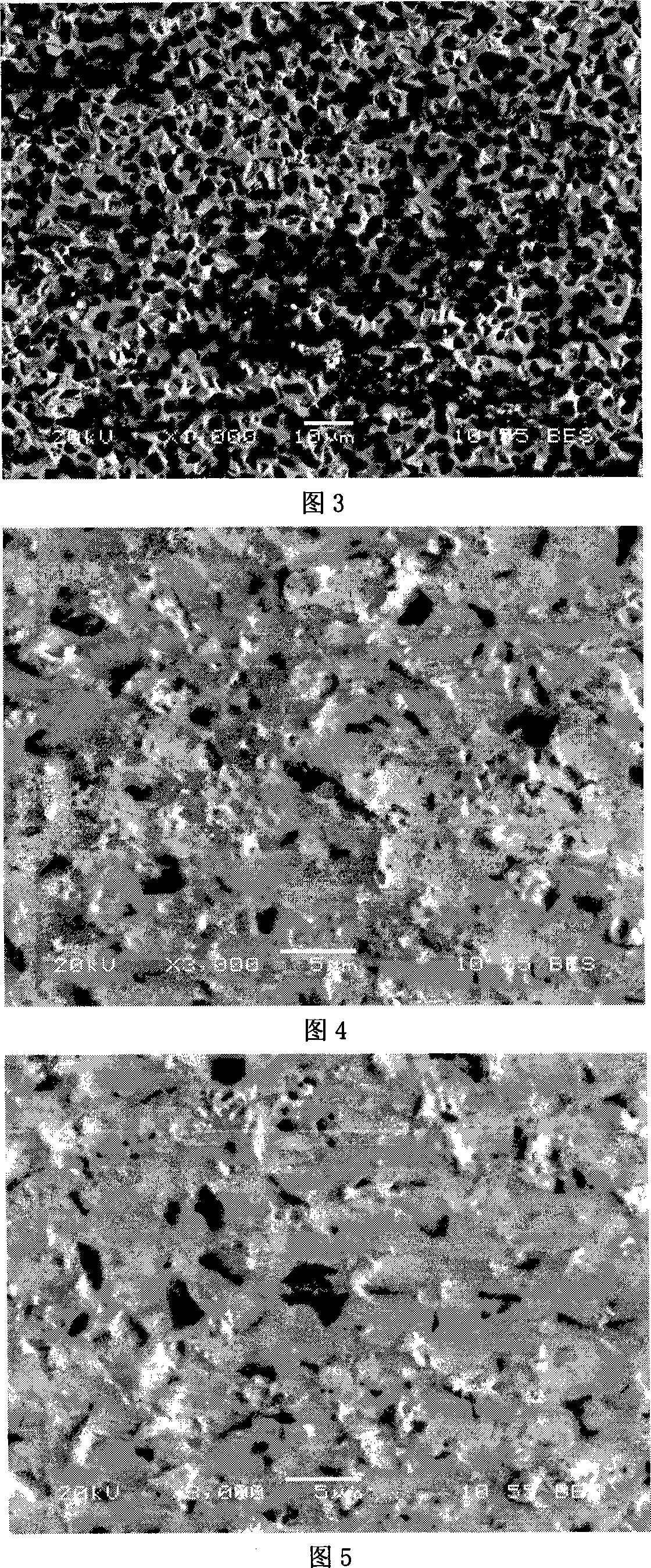

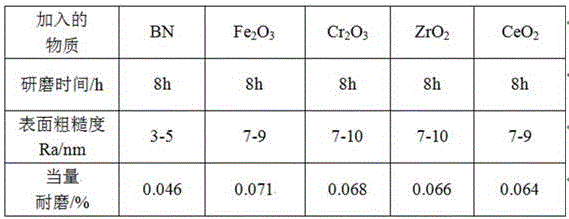

Zirconium oxide-corundum composite ceramic body for cement grinding mill and production process of zirconium oxide-corundum composite ceramic body

InactiveCN106478123AHigh strengthImprove wear resistanceOther chemical processesTunnel kilnComposite ceramic

The invention discloses a zirconium oxide-corundum composite ceramic body for a cement grinding mill and a production process of the zirconium oxide-corundum composite ceramic body. The ceramic body comprises alumina micro-powder, alumina whiskers, zirconium oxide and a binding agent. The production process includes: placing the raw materials above into a ball mill for wet milling, sieving, placing into a slurry tank, stirring and aging, removing iron, feeding into a spray drying tower for spraying pulverization, and conveying into a large bin for aging; using an extrusion molding method or an injection molding to prepare the aged powder into bases, feeding the bases into a high-temperature tunnel kiln, performing temperature-gradient sintering, grinding the sintered products, water and boron nitride in a ball mill, discharging, drying and packaging. The spherical ceramic body and the production process thereof have the advantages that the ceramic body is smooth in surface, high in hardness, high in wear resistance, high in impact resistance, low in equivalent abrasion and the like, the service life of the ceramic body is prolonged, production cost is lowered, and production efficiency is increased.

Owner:洛阳鹏飞耐磨材料股份有限公司

Diamond ultrathin saw bit with nickel aluminium alloy as base and manufacturing method thereof

The invention relates to a ni-al alloy-based diamond ultra-thin saw blade used for precise cutting in single (multi) crystal silicon, glass, ceramic, gem processing, etc. industries and the preparation method of the diamond ultra-thin saw blade. 50-70 units (volume percentage) of the nickel (5-20 micro meters) with the purity more than 99.9%, 10-30 units of aluminium powder (5-20 micro meters) and 20-30 units of titanium-plated artificial diamond grains (5-10 micro meters) are uniformly mixed in a three dimensional material mixer, then arranged into a die and cold pressed to a biscuit with the diameter dimension of Phi 25-200mm multiplied by 100-400 Mum on a four-column hydraulic press under a forming pressure of 100-500kgf / cm<2>; after that, a hot pressing and sintering is achieved by two sections; the heating of the mixture is firstly achieved in a vacuum hot pressing sintering furnace till the temperature is increased to 670-700 DEG C, and the temperature is kept for 5-60 minutes; after that, the temperature is increased to 750-800 DEG C and kept for 5-60 minutes with the hot pressure of 100-400kgf / cm<2>; the temperature is then gradually cooled to below 200 DEG C with the pressure in the furnace and the diamond saw blade can be gained after a discharge. The invention has the advantages of high strength, high rigidity, high ductility, high density, long service life, etc.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Low temperature sintered glass-ceramic composite insulating material and preparation method thereof

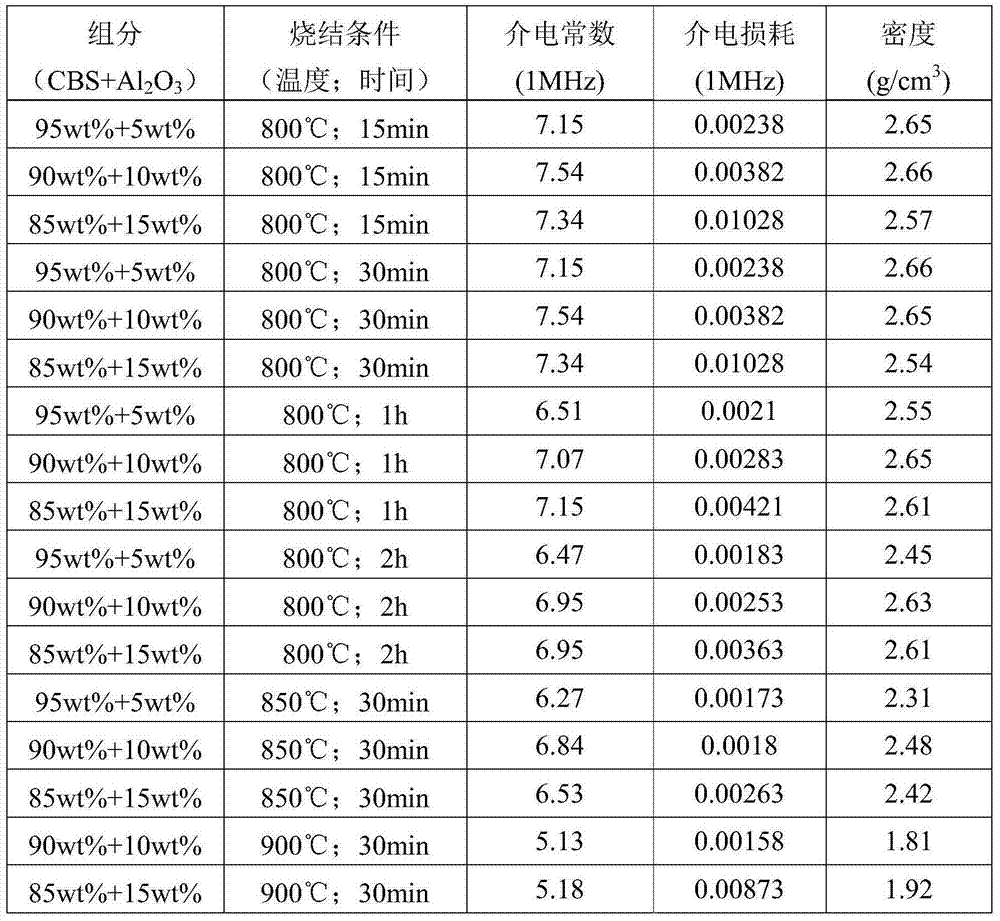

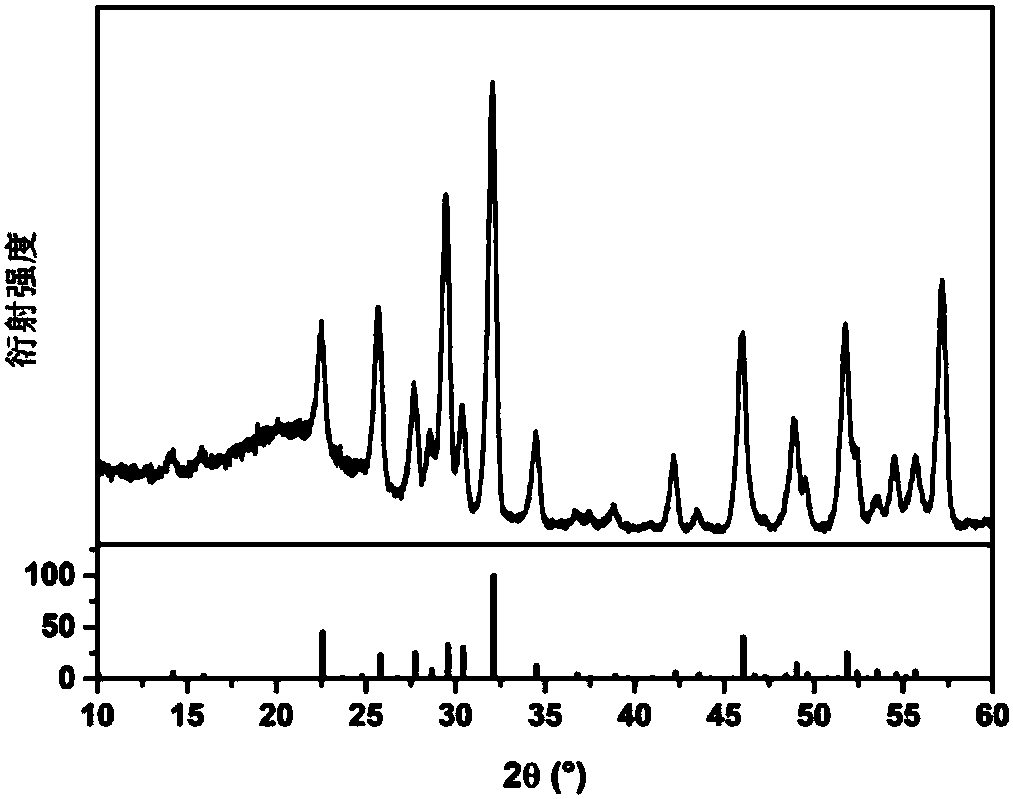

The invention relates to the field of the material science, and aims at providing a low temperature sintered glass-ceramic composite insulating material and a preparation method thereof. The chemical expression formula of the glass-ceramic composite insulating material is xAl2O3-(1-x)CBS, x is 5-15wt%, and CBS is 40wt%CaO-20wt%B2O3-40wt%SiO2. The addition of Al2O3 makes parts of Al2O3 fused into glass and reduces the CaSiO3 enrichment area, so the crystallization amount and the crystal growth are reduced to a certain degree, the viscosity increase of a molten glass phase is alleviated, and the densification effect is improved, thereby the Al2O3 / CBS composite insulating material maintains good dielectric properties and compactness, and can perfectly meet application demands of high tension transmission line insulation, microelectronic substrates and high frequency capacitance.

Owner:ZHEJIANG UNIV

Preparation method of KSr2Nb5O15 transparent ferroelectric ceramic

Owner:NORTHWESTERN POLYTECHNICAL UNIV

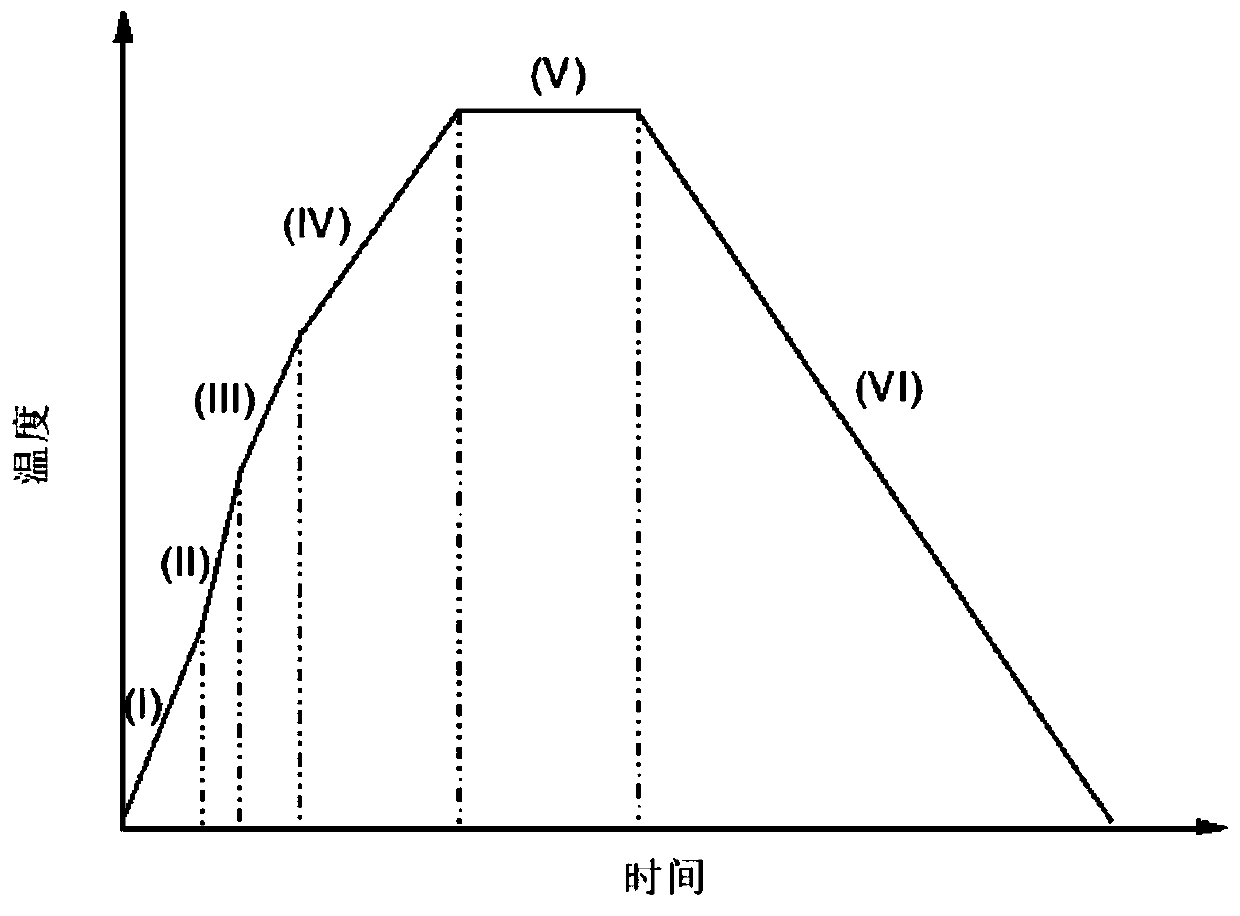

Normal-pressure multi-step sintering method for powder metallurgy of high-density Ti-Nb-Mo series alloy

ActiveCN111203531AHigh densityHomogeneous organizationTransportation and packagingMetal-working apparatusSintered titaniumCompressive strength

The invention provides a normal-pressure multi-step sintering method for powder metallurgy of a high-density Ti-Nb-Mo series alloy, and belongs to the technical field of alloys. According to the method, the multi-step sintering is carried out under normal pressure by adopting a temperature programming mode, and different protective atmospheres and gas flow rates are adopted at different temperature programming stages of the sintering, so that the capability of titanium hydride to improve the density of the powder metallurgy titanium alloy is maximally exerted, and the sintered titanium alloy is high in density and uniform and consistent in structure and performance. The results of the method show that the density of the Ti-Nb-Mo series alloy obtained by using the normal-pressure multi-stepsintering method can reach 99% or above, the average grain size is 30.2-39.7 microns, the yield strength of the alloy can reach 960 MPa, the compressive strength can reach 1287 MPa, and the criticalfailure strain is more than 0.7.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation process of aluminum oxide dispersion strengthened copper alloy

InactiveCN110184489AImproves uniformity and sintering propertiesLower sintering temperatureTransportation and packagingMetal-working apparatusPowder metallurgyHot press

The invention provides a preparation process of an aluminum oxide dispersion strengthened copper alloy and belongs to the field of nonferrous metal powder metallurgy materials. The preparation processspecifically comprises the following steps: S1, putting aluminum oxide dispersed copper alloy raw material powder in ball-milling equipment for ball-milling treatment; and S2, preparing the aluminumoxide dispersion strengthened copper alloy from the raw material powder after ball-milling treatment in the S1 through hot pressed sintering. By processing the aluminum oxide dispersed copper alloy powder by means of a ball-milling process, the uniformity and the sintering performance of the alloy powder are improved, so that the sintering temperature of the alloy is reduced and the densifying performance of the alloy is improved obviously. The aluminum oxide dispersion strengthened copper alloy which is high in density and good in mechanical property is obtained by hot pressed sintering. Theprocess method is simple, simplifies the preparation flow of the aluminum oxide dispersion strengthened copper alloy greatly, and is low in cost, stable in performance and quite suitable for scaled production.

Owner:中山麓科睿材科技有限公司

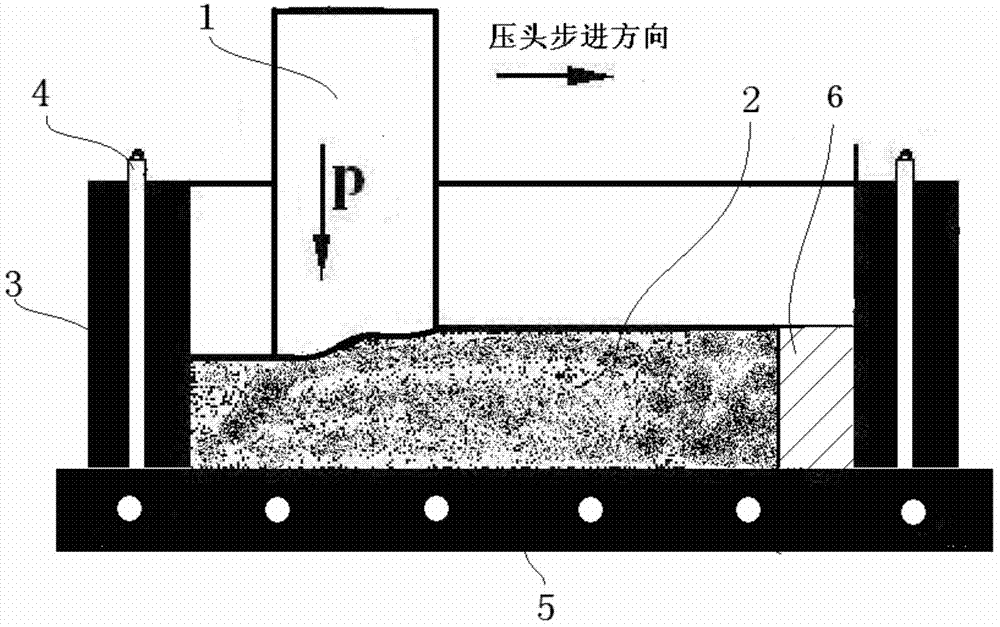

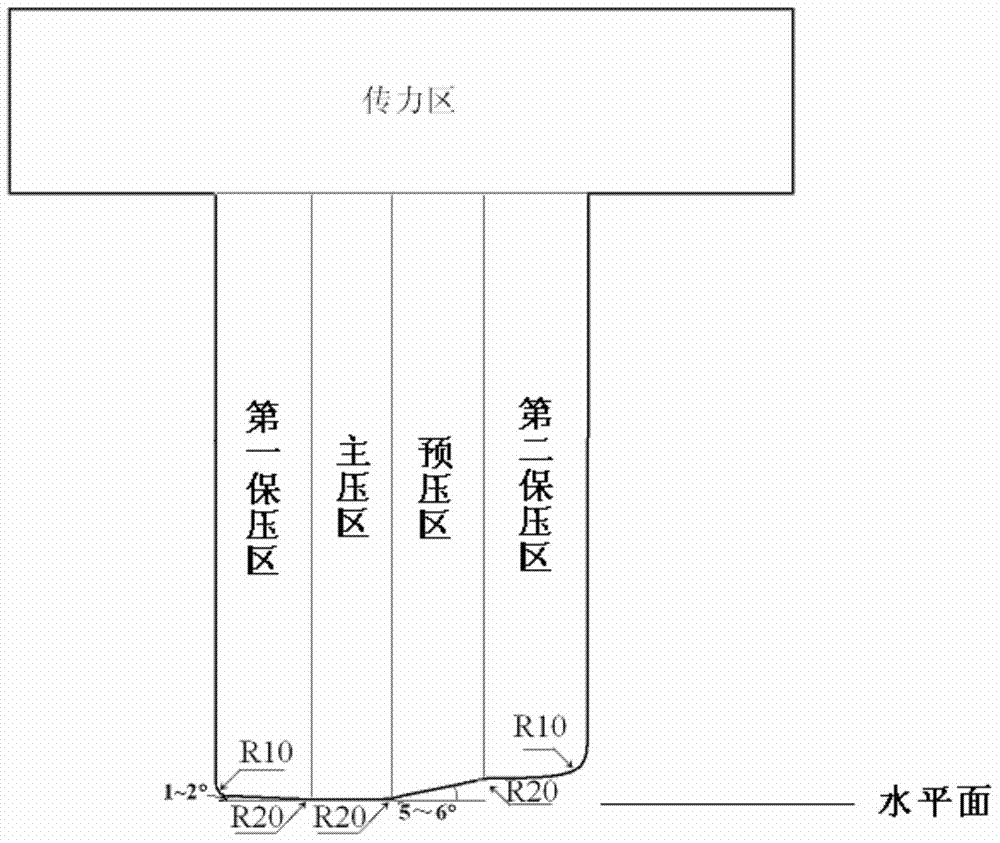

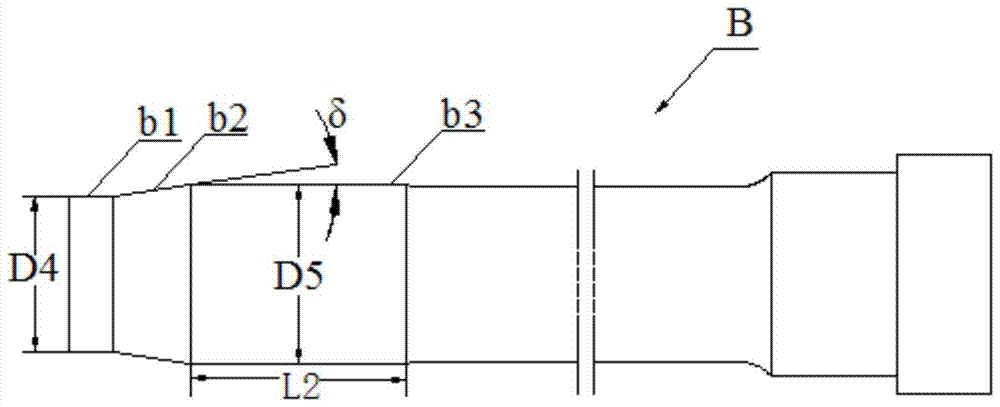

Pressing head and device for achieving densification of spray deposition porous panel and application thereof

Owner:HUAIHAI INST OF TECH

Preparation method of graphene-based compact composite material

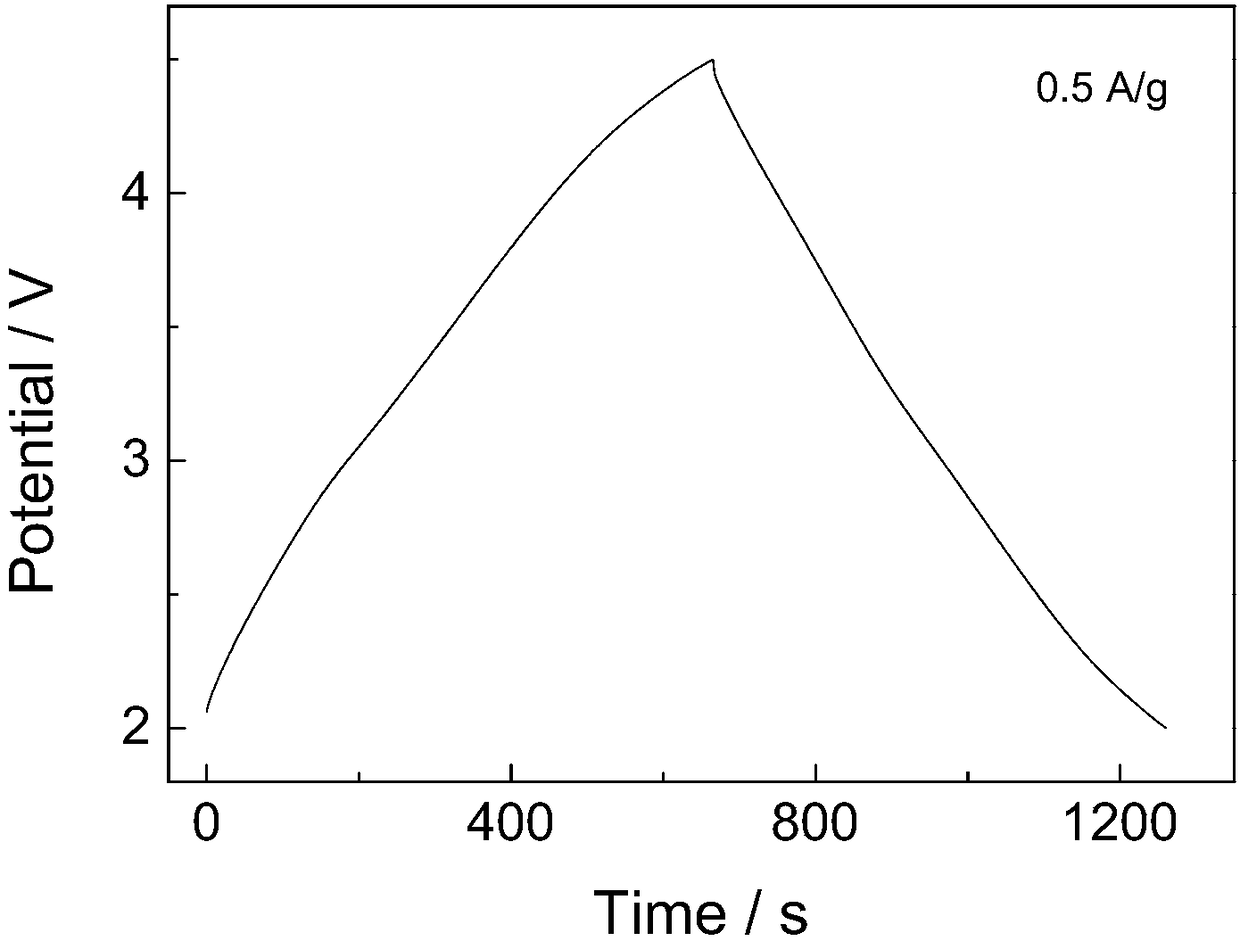

ActiveCN108364801AAvoid stackingIncrease profitMaterial nanotechnologyHybrid capacitor electrodesHigh densityEvaporation

The invention belongs to the technical field of energy storage, and particularly relates to a preparation method of a graphene-based compact composite material. The preparation method at least comprises the following steps of adding a dispersing liquid of an insoluble constituent into a graphene dispersing liquid, and performing full stirring to obtain a first mixed dispersing liquid; adding a reduction constituent, and performing full stirring to obtain a second mixed dispersing liquid; adding to a hydrothermal reaction kettle for hydrothermal reaction to obtain hydrogel; fully immersing thehydrogel in deionized water, removing impurity, performing evaporation, drying and moisture removal to obtain a product to be processed; and performing high-temperature thermal processing, and furtherremoving an oxygen-containing functional group to obtain the three-dimensional compact composite material. The pre-arrangement effect of the insoluble constituent during the rapid and compact formation process of a graphene network is promoted by the reduction constituent, gaps among other insoluble constituent particles are reduced by a shrinkage effect of the three-dimensional graphene networkduring the solvent removal process, material compactness is achieved, so that the composite material with relatively high density is obtained.

Owner:TIANJIN UNIV

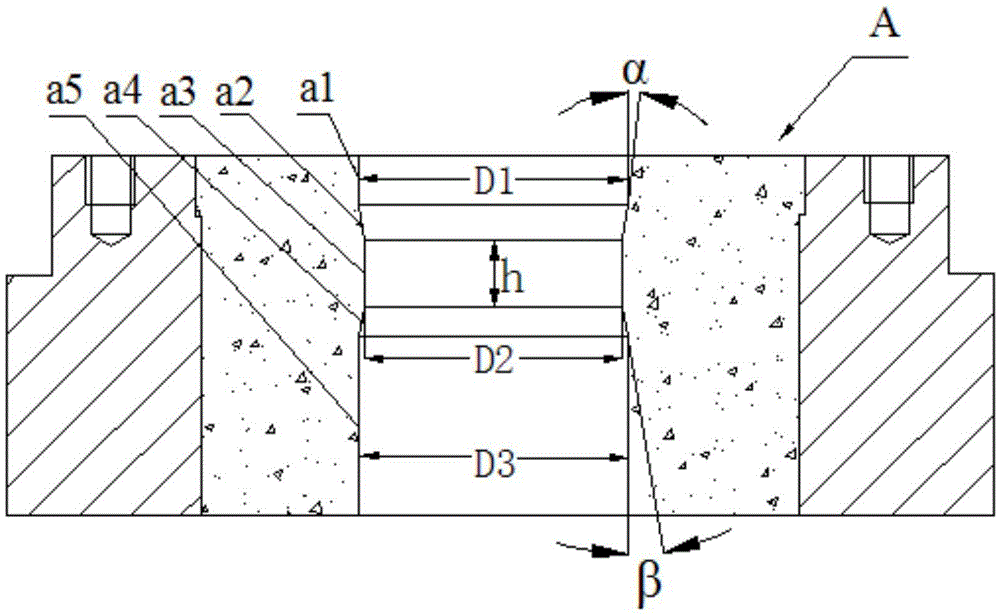

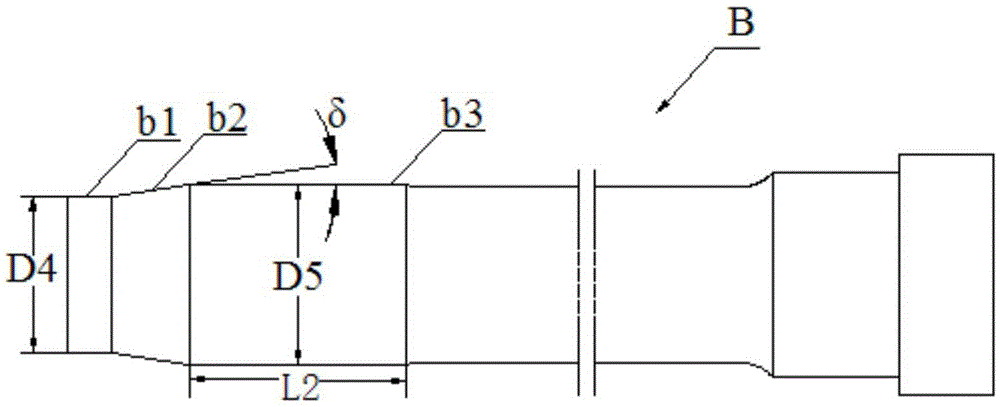

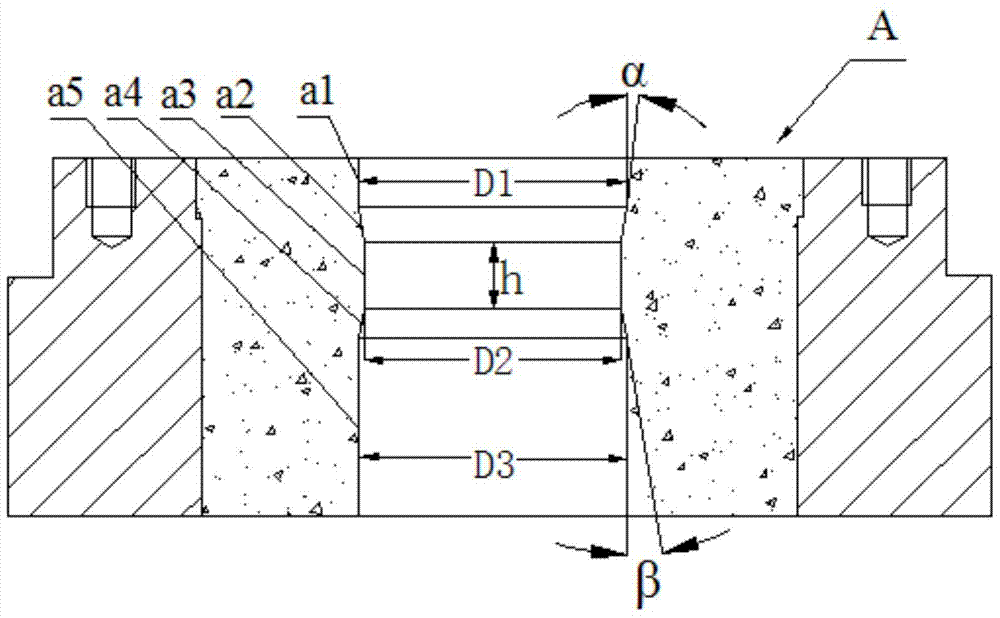

Preparation method of aluminium base powder metallurgy part with densifying surface

ActiveCN105463276AImprove the densification effectImprove wear resistanceRelative intensityHigh intensity

The invention relates to a preparation method of an aluminium base powder metallurgy part with a densifying surface. According to the preparation method, a special extrusion female die used for extruding the external surface of a part and an extrusion core rod used for extruding the internal surface of the part are adopted, an upper punch die and a lower punch die which are used for clamping the part achieve an auxiliary effect, and particular extrusion steps are adopted for matching. During use, the part is fixed, the corresponding extrusion die is moved to complete extrusion, and in such a way, the crack defect of the part generated after the part is extruded and then subjected to die stripping is avoided. Compared with energy required for surface plastic property densifying after the sintering step in the prior art, the preparation method has the advantages that large deformation depth is obtained in small extrusion allowance; the energy requirement is remarkably reduced; the production cost is reduced; the densifying degree is improved; the whole intensity of a product after extrusion can exceed 2.75g / cm<3>; the relative intensity of the product surface can reach 99% or above; the coverage rate of a densifying layer is high; the aluminium base powder metallurgy part has good abrasive resistance and high intensity.

Owner:NBTM NEW MATERIALS GRP

Preparation method for iron-based powder metallurgy part with compact surface

The invention relates to a preparation method for an iron-based powder metallurgy part with a compact surface. An extrusion female die used for extruding the outer surface of the part and an extrusion mandrel used for extruding the inner surface of the part are specially designed, and an upper punching die and a lower punching die which can clamp the part are used in an auxiliary manner. In the use process, the part is fixed, the corresponding extruding dies are moved to complete extrusion, and by means of the manner, the defect that the part cracks when die stripping is conducted after extrusion is completed can be overcome. Compared with energy required when surface plasticity compaction is conducted after the sintering step in the prior art, the large deformation depth can be obtained through small extrusion allowance, the energy requirement is remarkably lowered, the production cost is reduced, the compaction degree is improved, the overall product density can exceed 7.60 g / cm<3> after extrusion, the product surface relative density can reach 99% or above after extrusion, the compact layer coverage rate is high, and therefore the iron-based powder metallurgy part can have the beneficial effects of being high in precision and strength.

Owner:连云港富驰智造科技有限公司

Application of titanium silicon carbide to hard alloy

InactiveCN106834866AImprove compactnessImprove the densification effectMicrometerOxidation resistant

The invention relates to the powder metallurgy technology, and discloses a high-temperature-oxidation-resistant high-strength Ti3SiC2 hard alloy. The hard alloy is composed of tungsten carbide powder or tungsten carbide composite powder, cobalt powder and Ti3SiC2 powder, wherein the mass ratio of the Ti3SiC2 powder to the hard alloy is 0.1% to 5%; the purity of the Ti3SiC2 powder is larger than 98%, and the particle size is 0.01 micrometer to 10 micrometers. The Ti3SiC2 in the hard alloy can refine hard alloy grains, can hinder grain growth and can strengthen hard alloy compactness; and the actual density of either high-cobalt-alloy or low-cobalt-alloy can reach 99.9% of the theoretical density.

Owner:JIANGXI UNIV OF SCI & TECH

Fire-resistant flame-retardant tin-plated copper wire for 5G communication

ActiveCN113130127AGood fire prevention effectImprove the densification effectClimate change adaptationInsulated cablesCopper wireLanthanum

The invention discloses a fire-resistant flame-retardant tin-plated copper wire for 5G communication. The fire-resistant flame-retardant tin-plated copper wire comprises the following raw materials in percentage by weight: 20-30 parts of a copper wire substrate, 10-20 parts of a coating agent and 5-10 parts of a sintering material. The preparation method of the coating agent comprises the following steps of: S1, firstly feeding montmorillonite into a rare earth lanthanum chloride solution with the mass fraction of 20-30%, and stirring the mixture for 20-30 minutes, wherein the stirring rotating speed is 100-200r / min. The copper wire substrate is coated by the coating agent, the coating agent is activated and modified by adopting montmorillonite and the rare earth lanthanum chloride solution, and finally, irradiation treatment is performed, so that active energy can be excited, meanwhile, montmorillonite has very high adsorbability and can carry a flame-retardant liquid to be adhered to the copper wire substrate, bentonite in the flame-retardant liquid is of a lamellar structure and can achieve a middle blocking effect, thus external heat of a sintering material is prevented from being in contact with the coating agent, so that a coating layer is prevented from being delaminated, and a very good fireproof effect is achieved.

Owner:JIANGXI FUHONG METAL CO LTD

A high-density non-magnetic steel balance weight part and its preparation method

ActiveCN106544570BSolve the problem of poor compressionHigh strengthTransportation and packagingMetal-working apparatusElectrolysisLithium stearate

The invention discloses a high-density non-magnetic steel balance weight part and a preparation method thereof. In terms of mass percentage, the raw materials of the high-density non-magnetic steel balance weight parts include the following components: WC powder 6‑10%, phosphor bronze powder 10%, electrolytic pure copper powder 15‑25%, lithium stearate lubricant 1 %, the rest is Fe-Mn-C pre-alloyed powder. The preparation method of the high-density non-magnetic steel balance weight part includes the following steps: (1) Weighing each component according to the mass percentage and mixing them uniformly in a mixer; (2) Compressing the uniformly mixed mixed powder; (3) High temperature sintering. The preparation method of the invention has the advantages of simple process, controllable cost, near-net shape and controllable dimensional change, and high-density non-magnetic steel balance weight parts with a density of 7.7-7.9g / cm3 can be prepared.

Owner:GUANGDONG YUEHAI HUAJIN TECH CO LTD

Production process of abrasive block with ultra-low porosity and high density

The invention discloses a production process of an abrasive block with ultra-low porosity and high density, and belongs to the field of rail transportation equipment. The components and parts by weight are as follows: 50-65 parts of iron powder, 5-8 parts of silicon carbide powder, 10-15 parts of steel fiber, 5-10 parts of a coupling agent, and 5-10 parts of resin powder. The main process flow comprises: vacuum granulation, vacuum hot press formation, and gas furnace solidification. The above optimized process can reduce the porosity of the abrasive block and densify the product, and at the same time, because the whole process does not need exhaust treatment, the combination of the mixed materials and the steel back is tighter, and a high-quality abrasive block with good appearance can beobtained, and does not produce metal damascene and hot cracking during use. The wear resistance of the abrasive block can be improved.

Owner:马鞍山市雷狮轨道交通装备有限公司

Method for preparing proppant in high intensity

The present invention provides a preparation method of high-strength proppant. Said method includes the following steps: mixing bauxite raw ore powder, rare earth concentrate, combustible substance and binding agent according to a certain mixing ratio, grinding them into powder material, sphere-forming to obtain blank spheres, screen to obtain semi-finished product spheres, roasting at 1250-1500 deg.C, further screening, polishing, removing dust, finally covering the spheres with phenol-formaldehyde resin so as to obtain finished product. Said invention also provides its application range.

Owner:关昌烈 +1

A two-time molding method for a ceramic ball for cement grinding

A two-time molding method for a ceramic ball for cement grinding is disclosed. The method includes a step of mixing raw materials and pressing the raw material mixture into a ball blank, a step of sintering the ball blank, putting a sintered product after sintering into a ball mill, adding water and boron nitride, grinding, discharging a product, and drying the product to obtain the ceramic ball. Smoothness, wear resistance, impact resistance and other properties of the ceramic ball are improved, ceramic balls having surface defects, low hardness and low stress tolerance are screened, and the production efficiency is increased. In addition, produced cement is uniform in fineness, stable in performance and low in scatter difference, and therefore abnormal deformation is not generated in a later period, and cement quality is ensured.

Owner:洛阳鹏飞耐磨材料股份有限公司

A preparation method of copper-based powder metallurgy parts with densified surface

The invention relates to a method for preparing a copper-based powder metallurgy part with a densified surface. In order to make the prepared copper-based powder metallurgy part have better density and strength, the invention designs an extrusion process for extruding the outer surface of the part. The die and the extrusion mandrel on the inner surface of the extruded part are supplemented by an upper punching die and a lower punching die that can clamp the part. When in use, the part is fixed and the corresponding extrusion die is moved to complete the extrusion. Such a method can avoid the defect that cracks are prone to appear in the part after the extrusion is completed; compared with the energy required for the surface plastic densification after the sintering step in the prior art, the present invention can use less extrusion The margin gets a larger deformation depth, and significantly reduces the energy demand, thereby reducing the production cost and improving the degree of densification; the shape of the prepared blank part is closer to the shape of the final product, so the extrusion margin is small, and the impact on the mold The loss is small, which prolongs the life of the mold to a certain extent.

Owner:NBTM NEW MATERIALS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com