Method for preparing proppant in high intensity

A manufacturing method and proppant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing glass phase, restricting strength, and high energy consumption of grinding powder, so as to reduce raw material costs and energy consumption, Improved chemical stability and reduced product density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Crushing the bauxite raw ore until the particle size is less than 5mm to obtain the main material.

[0020] 2) Mix 100 parts of the above-mentioned main ingredients with 0.5 parts of rare earth concentrate, 10 parts of combustibles (charcoal) and 0.05 parts of binder (industrial dextrin) for 5 minutes to obtain a mixture.

[0021] 3) Grinding the above-mentioned mixture until the particle size is less than 300 mesh to obtain co-grinding powder;

[0022] 4) Use the co-grinding powder to form a ball to obtain a green ball with a roundness and a sphericity of 0.9.

[0023] 5) Sieve the green balls with a double-layer sieve, the upper sieve has 18 meshes, the lower sieve has 30 meshes, and the green balls on the sieve with a particle size greater than 18 meshes are crushed, and then return to step 4) to form balls, and the particle size The green ball under the sieve of less than 30 mesh returns to step 4) into a ball, and the green ball with a particle size of 30 to 18...

Embodiment 2

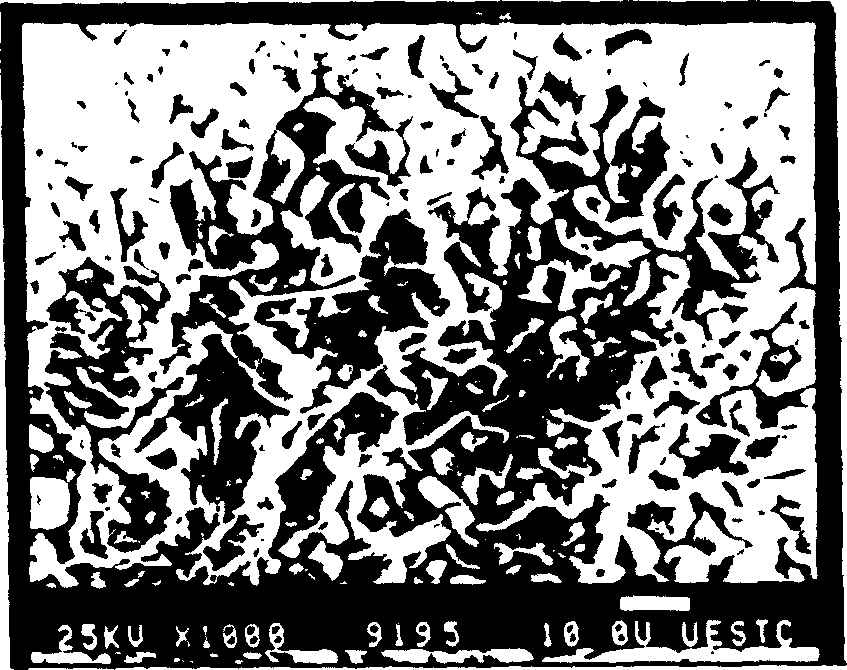

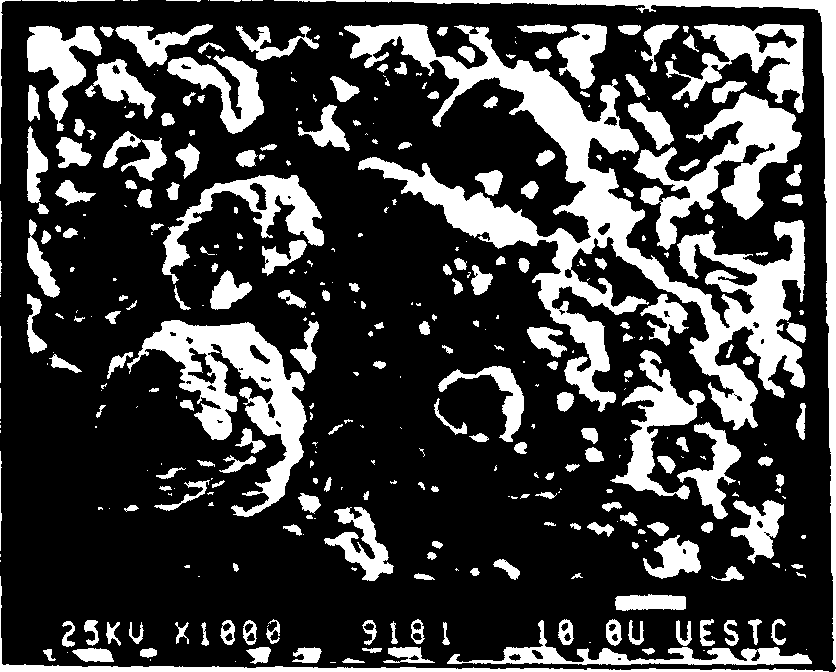

[0028] 100 parts of bauxite raw ore, 3.5 parts of rare earth concentrate, 8 parts of combustibles (carbonized rice husk), 0.03 parts of binder (methyl cellulose), roasting temperature 1350-1400 ° C, roasting time 3 hours, step 8) The thermosetting temperature is 150° C., and the rest are the same as in Example 1. The performance index is shown in Table 1, and the scanning electron microscope picture is shown in figure 2 shown.

Embodiment 3

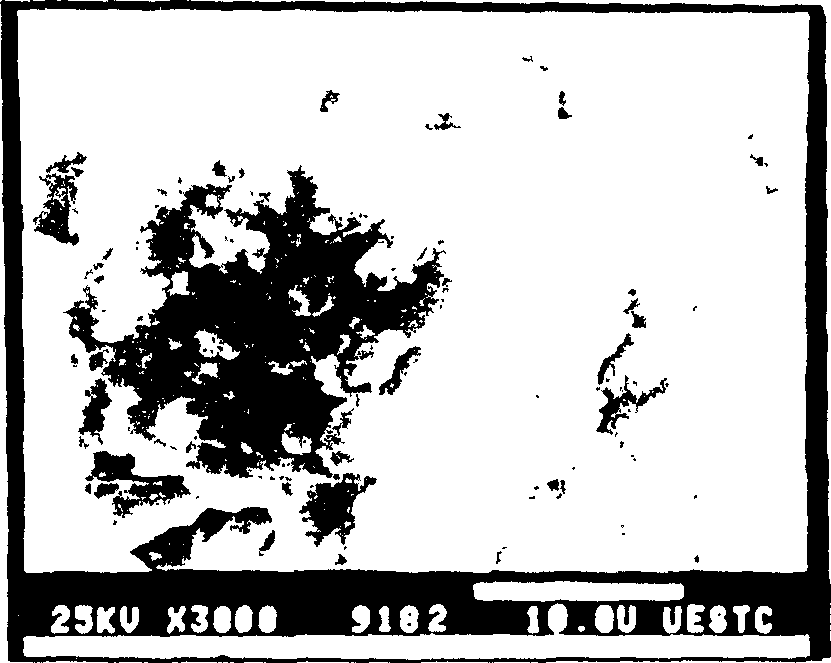

[0030] 100 parts of bauxite raw ore, 5 parts of rare earth concentrate, 5 parts of combustibles (carbonized rice husk), 0.02 parts of binder (polyvinyl alcohol), roasting temperature 1450-1500 ° C, roasting time 1 hour, step 8) heating The solidification temperature is 180°C. All the other are with embodiment 1. The performance index is shown in Table 1, and the scanning electron microscope picture is shown in image 3 shown.

[0031] Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com