Preparation method of KSr2Nb5O15 transparent ferroelectric ceramic

A ferroelectric ceramic and transparent technology is applied in the preparation of transparent ferroelectric ceramics, KSr2Nb5O15 transparent ferroelectric ceramics and the field of preparation thereof, which can solve the problems of insufficient density, low optical transmittance, increase ceramic density, etc. The effect of low equipment requirements, high visible light transmittance and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

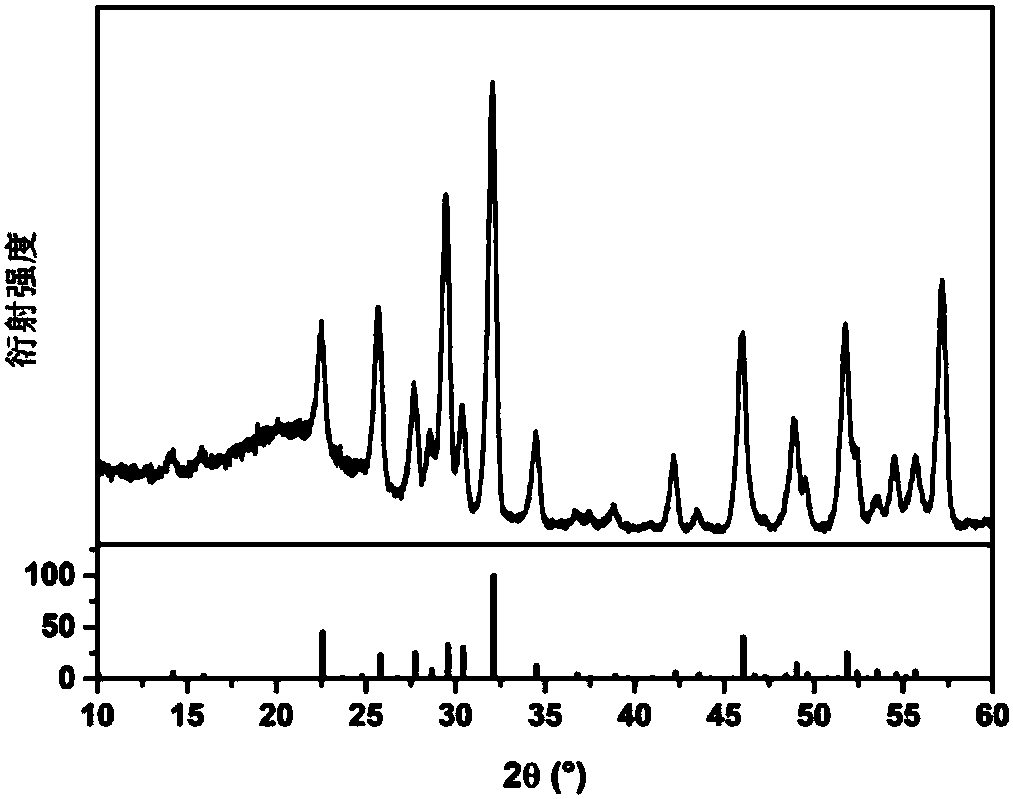

[0026] This embodiment is a KSr 2 Nb 5 o 15 The preparation method of transparent ferroelectric ceramics, the concrete process is:

[0027] Step 1, mixing ingredients. Rod-shaped KSr prepared by molten salt method 2 Nb 5 o 15 Microcrystalline powder as raw material, with Bi 2 o 3 The powder is a sintering aid, according to KSr 2 Nb 5 o 15 Microcrystalline powder: Bi 2 o 3 The weight ratio of powder = 1000:3 weighs the KSr 2 Nb 5 o 15 Microcrystalline powder and Bi 2 o 3 Powder; in the present embodiment, the KSr taken by weighing 2 Nb 5 o 15 The microcrystalline powder is 10g, and the Bi 2 o 3 The powder is 0.03g. The KSr 2 Nb 5 o 15 The morphology of the microcrystalline powder is rod-shaped; the rod-shaped KSr 2 Nb 5 o 15 The microcrystalline powder has a diameter of 1-3 μm and a length of 5-15 μm. The KSr 2 Nb 5 o 15 Microcrystalline powder and Bi 2 o 3 Powder mixing means to complete the mixing of ceramic powder and sintering aids.

[002...

Embodiment 2

[0036] This embodiment is a KSr 2 Nb 5 o 15 The preparation method of transparent ferroelectric ceramics, the concrete process is:

[0037] Step 1, mixing ingredients. Rod-shaped KSr prepared by molten salt method 2 Nb 5 o 15 Microcrystalline powder as raw material, with Bi 2 o 3 The powder is a sintering aid, according to KSr 2 Nb 5 o 15 Microcrystalline powder: Bi 2 o 3 The weight ratio of powder = 1000:6 weighs the KSr 2 Nb 5 o 15 Microcrystalline powder and Bi 2 o 3 Powder; in the present embodiment, the KSr taken by weighing 2 Nb 5 o 15 The microcrystalline powder is 10g, and the Bi 2 o 3 The powder is 0.06g. The KSr 2 Nb 5 o 15 The morphology of the microcrystalline powder is rod-shaped; the rod-shaped KSr 2 Nb 5 o 15 The microcrystalline powder has a diameter of 1-3 μm and a length of 5-15 μm. The KSr 2 Nb 5 o 15 Microcrystalline powder and Bi 2 o 3 Powder mixing means to complete the mixing of ceramic powder and sintering aids.

[003...

Embodiment 3

[0045] This embodiment is a KSr 2 Nb 5 o 15 The preparation method of transparent ferroelectric ceramics, the concrete process is:

[0046] Step 1, mixing ingredients. Rod-shaped KSr prepared by molten salt method 2 Nb 5 o 15 Microcrystalline powder as raw material, with Bi 2 o 3 The powder is a sintering aid, according to KSr 2 Nb 5 o 15 Microcrystalline powder: Bi 2 o 3 The weight ratio of powder = 1000:4 weighs the KSr 2 Nb 5 o 15 Microcrystalline powder and Bi 2 o 3 Powder; in the present embodiment, the KSr taken by weighing 2 Nb 5 o 15 The microcrystalline powder is 10g, and the Bi 2 o 3 The powder is 0.04g. The KSr 2 Nb 5 o 15 The morphology of the microcrystalline powder is rod-shaped; the rod-shaped KSr 2 Nb 5 o 15 The microcrystalline powder has a diameter of 1-3 μm and a length of 5-15 μm. The KSr 2 Nb 5 o 15 Microcrystalline powder and Bi 2 o 3 Powder mixing means to complete the mixing of ceramic powder and sintering aids.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com