A high-density non-magnetic steel balance weight part and its preparation method

A technology of balance block and non-magnetic steel, applied in the field of powder metallurgy, can solve the problems of unsuitability for industrial production, low sintered blank density, limited product size, etc., and achieves the effects of good practicability, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

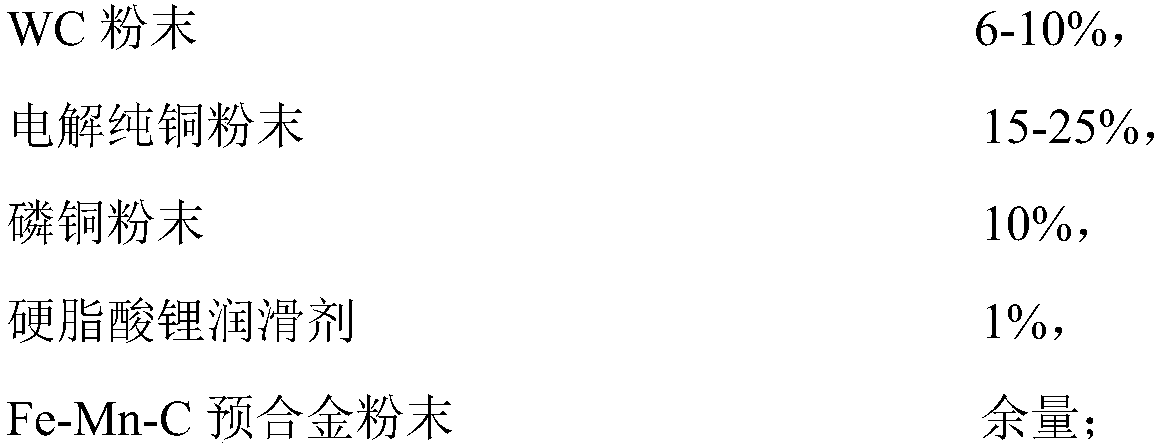

[0033] (1) According to mass percentage, weigh 8% WC powder (particle size 50-100μm, C mass fraction is 7%), 10% phosphor copper powder (particle size is 5-20μm, P mass fraction is 8%), 20% Electrolytic pure copper powder (5-10 μm), 1% lithium stearate lubricant, and the rest Fe-26Mn-0.5C pre-alloyed powder (particle size 10-60 μm), and mixed in a V-shaped mixer for 60 minutes, Obtain a homogeneously mixed powder;

[0034] In the Fe-26Mn-0.5C pre-alloyed powder, according to the mass percentage, manganese is 30%, carbon is 0.5%, and the rest is iron. Regular shape powder, powder particle size less than 60μm, oxygen content 1.5wt%, powder fluidity 25s / 50g;

[0035] (2) Form the obtained mixed powder on a 100t hydraulic press with a pressure of 700Mpa to obtain a density of 6.46 g / cm 3 The balance weight parts are compacted;

[0036] (3) Under the protection of the decomposed ammonia atmosphere, the compacted parts of the balance block were sintered in a mesh belt furnace at ...

Embodiment 2

[0038] (1) According to mass percentage, weigh 10% WC powder (particle size 50-100 μm, C mass fraction is 7%), 10% phosphor copper powder (particle size 5-20 μm, P mass fraction is 8%), 25% electrolytic Pure copper powder (5-10 μm), 1% lithium stearate lubricant, the rest is Fe-24Mn-0.3C pre-alloyed powder (particle size 10-60 μm), and mixed in a V-type mixer for 85 minutes, Obtain a homogeneously mixed powder;

[0039] In the Fe-24Mn-0.3C pre-alloyed powder, by mass percentage, manganese is 28%, carbon is 0.3%, and the rest is iron. After smelting, it is made into pre-alloyed Fe-24Mn-0.3C by water atomization. Regular shape powder, powder particle size less than 60μm, oxygen content 1wt%, powder fluidity 30s / 50g;

[0040] (2) Form the obtained mixed powder on a 100t hydraulic press with a pressure of 800Mpa to obtain a density of 6.66 g / cm 3 The balance weight parts are compacted;

[0041] (3) Under the protection of the decomposed ammonia atmosphere, the compacted parts o...

Embodiment 3

[0043] (1) According to mass percentage, weigh 6% WC powder (particle size 50-100μm, C mass fraction is 7%), 10% phosphor copper powder (particle size 5-20μm, P mass fraction is 8%), 15% electrolytic Pure copper powder (5-10 μm), 1% lithium stearate lubricant, and the rest are Fe-20Mn-0.1C pre-alloyed powder (particle size 10-60 μm), and mixed in a V-type blender for 90 minutes to obtain Mixed powder evenly;

[0044] In the Fe-20Mn-0.1C pre-alloyed powder, by mass percentage, manganese is 26%, carbon is 0.1%, and the rest is iron. After smelting, it is made into pre-alloyed Fe-20Mn-0.1C irregular Shaped powder, the powder particle size is less than 60μm, the oxygen content is 2wt%, and the powder fluidity is 28s / 50g;

[0045] (2) Form the obtained mixed powder on a 100t hydraulic press with a pressure of 850Mpa to obtain a density of 6.7g / cm 3 The balance parts compact;

[0046] (3) Under the protection of the decomposed ammonia atmosphere, the compact of the balance block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com