Low temperature sintered glass-ceramic composite insulating material and preparation method thereof

A technology of glass ceramics and composite insulation, applied in the field of material science, can solve the problems of poor process controllability, large energy consumption, and high sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

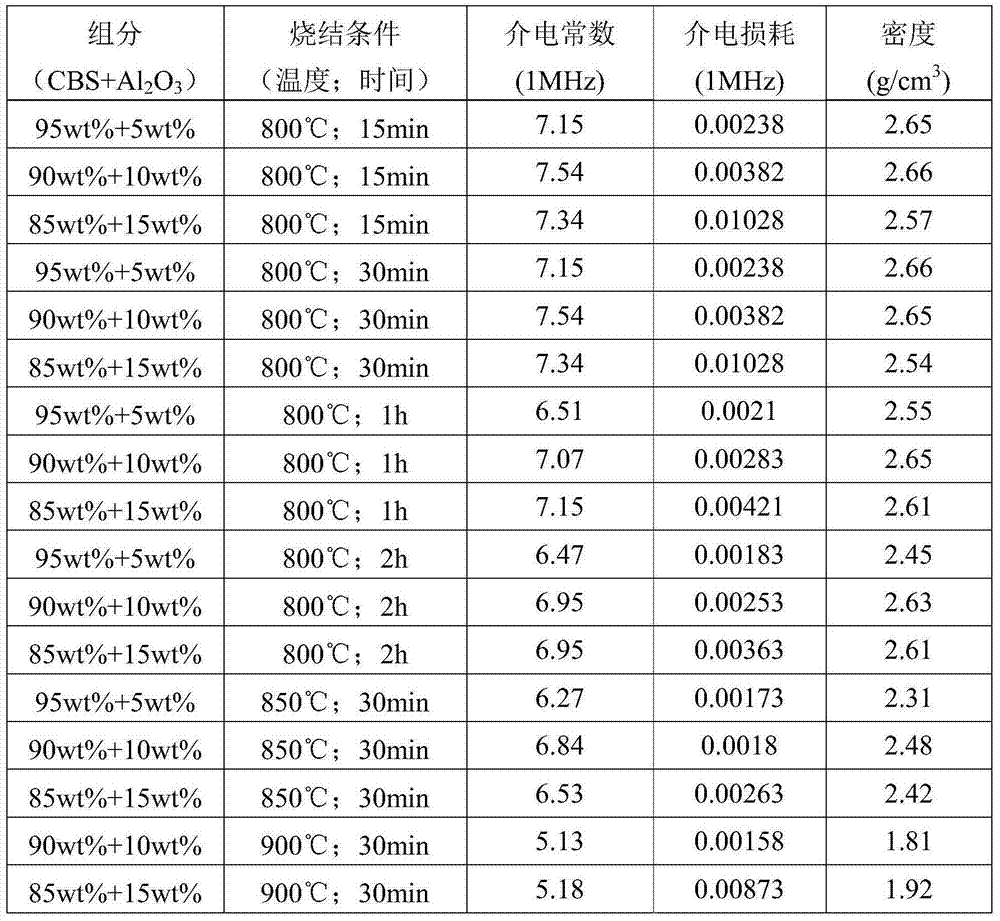

Examples

Embodiment Construction

[0015] The following examples can make those skilled in the art understand the present invention more fully, but do not limit the present invention in any way:

[0016] The present invention will be further described below in conjunction with embodiment.

[0017] (1) The composition formula of CBS glass is CaO: B 2 o 3 : SiO 2 The mass percentage is 40%: 20%: 40%. First weigh the CBS glass raw material according to the formula, where B 2 o 3 with H 3 BO 3 form introduced, and B 2 o 3 with the introduced H 3 BO 3 The molar ratio is 1:2; CaO to CaCO 3 form introduced, and CaCO 3 The molar ratio to CaO is 1:1.

[0018] Each raw material was added into a planetary ball mill for ball milling and mixing for 4 hours, and was melted at 1450° C. for 4 hours in an alumina crucible. The melted glass was quenched in water, crushed through a 20-mesh sieve, and the sieved glass powder was put into a planetary ball mill jar for ball milling for 4 hours to obtain CBS glass powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com