Copper/graphite compound material and preparation method thereof

A composite material and manufacturing method technology, applied in metal material coating process, hot-dip plating process, coating, etc., can solve the problems of unsatisfactory dipping composite effect and high equipment, and achieve good friction and lubrication performance, high mechanical strength and The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The copper / graphite composite material of the present invention uses carbon graphite as the matrix material and tin bronze alloy as the impregnating metal.

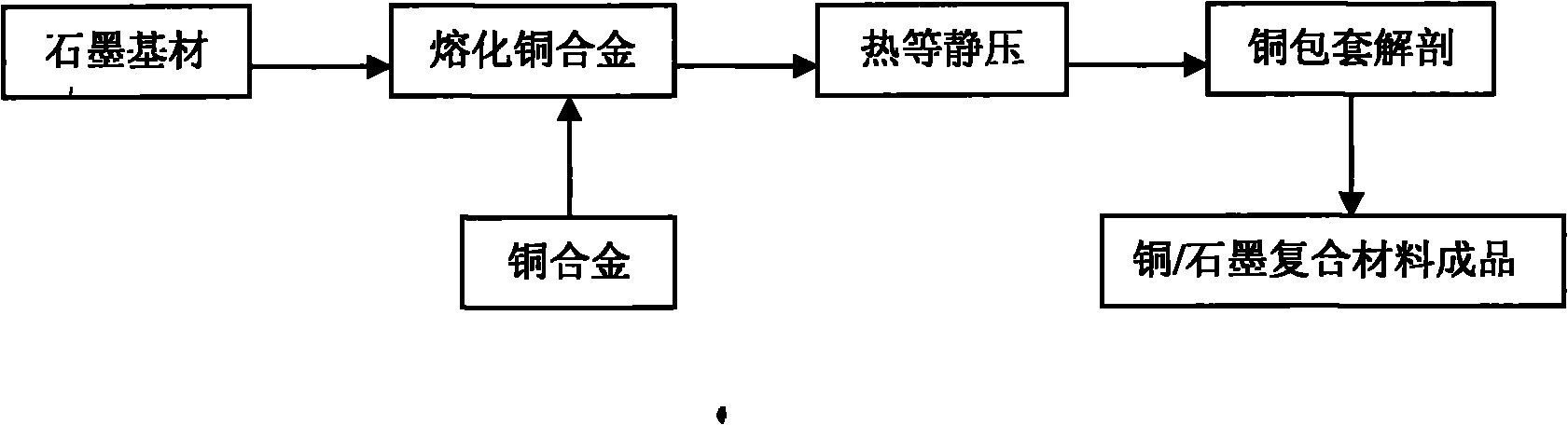

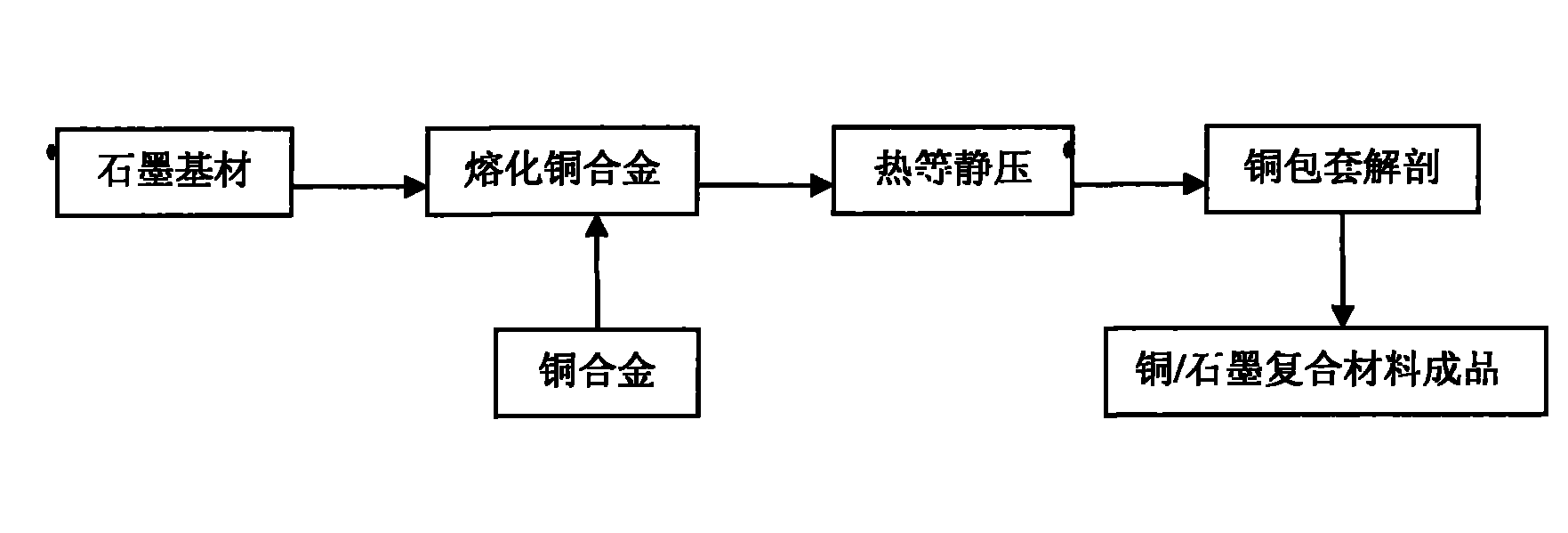

[0024] Such as figure 1 As shown, the above-mentioned copper / graphite composite material manufacturing method is as follows:

[0025] (1) The carbonaceous graphite material block is processed according to the needs; then the tin bronze alloy is melted into a molten liquid in the heat treatment furnace, the carbonaceous graphite material block is immersed, and the copper sheath covering the graphite material block is formed after cooling. The used tin-bronze alloy composition includes 5.2% by mass of tin, and the rest is copper; the melting of the tin-bronze alloy is at a temperature of 1150°C for 12 minutes. The density of carbon graphite used is 1.50g / cm 3 , The open porosity is 22.9%, the Shore hardness is 55HS, and the compressive strength is 70MPa.

[0026] (2) Put the copper sheath obtained in step (1) into a hot i...

Embodiment 2

[0030] The copper / graphite composite material of the present invention uses carbon graphite as the matrix material and tin bronze alloy as the impregnating metal.

[0031] Such as figure 1 As shown, the manufacturing method of the above-mentioned copper / graphite composite material is as follows:

[0032] (1) The carbonaceous graphite material block is processed according to the needs; then the tin bronze alloy is melted into a molten liquid in the heat treatment furnace, the carbonaceous graphite material block is immersed, and the copper sheath covering the graphite material block is formed after cooling. The density of carbon graphite used is 1.60g / cm 3 , The open porosity is 18.9%, the Shore hardness is 55HS, and the compressive strength is 80MPa. The used tin-bronze alloy composition includes 3% by mass of tin, and the rest is copper; the tin-bronze alloy has a melting temperature of 1100°C and a heat preservation time of 20 minutes.

[0033] (2) Put the copper sheath obtained ...

Embodiment 3

[0037] The copper / graphite composite material of the present invention uses carbon graphite as the matrix material and tin bronze alloy as the impregnating metal.

[0038] Such as figure 1 As shown, the above-mentioned copper / graphite composite material manufacturing method is as follows:

[0039] (1) The carbonaceous graphite material block is processed according to the needs; then the tin bronze alloy is melted into a molten liquid in the heat treatment furnace, the carbonaceous graphite material block is immersed, and the copper sheath covering the graphite material block is formed after cooling. The density of carbon graphite used is 1.60g / cm 3 , The open porosity is 18.9%, the Shore hardness is 55HS, and the compressive strength is 80MPa. The used tin-bronze alloy composition includes 5.2% by mass of tin, and the rest is copper. The tin-bronze alloy is melted at a temperature of 1200°C in the heat treatment furnace for 15 minutes.

[0040] (2) The copper sheath obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com