Preparation method of energy-saving floor tile

A floor tile and a technology for preparing steps, which are applied in chemical instruments and methods, materials for heat exchange, construction, etc., can solve the problems of high energy consumption of floor tiles, poor energy-saving and temperature control performance of floor tiles, and low energy utilization efficiency, etc. The effect of increased heat storage capacity, improved thermal insulation performance, and improved closed cell ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

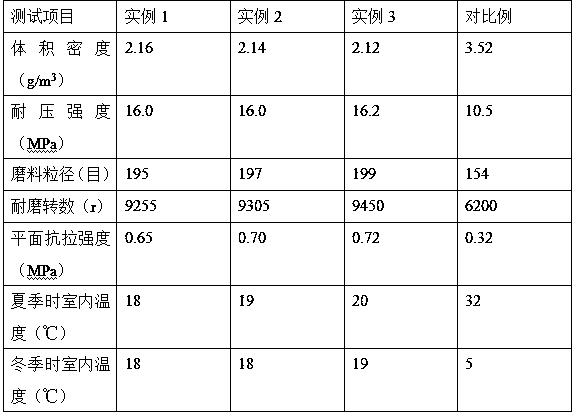

Examples

Embodiment Construction

[0024]Put 10-12mL emulsifier OP-10 in the conical flask, pour 200-220mL hydrochloric acid with a mass fraction of 5% into the conical flask, and after the emulsifier is completely dissolved, add 40-45mL For liquid paraffin, place the Erlenmeyer flask in a water bath, heat up to 80-85°C, and use a magnetic stirrer to homogeneously emulsify at a speed of 800-1000r / min for 30-35min to obtain an oil-in-water emulsion; Transfer the emulsion to a three-necked flask equipped with a stirrer and a constant-pressure dropping funnel, start the agitator, stir at a speed of 250-300r / min, and use a constant-pressure dropping funnel at a dropping rate of 2-3mL / min to the three-necked flask. Add 200 mL of sodium metasilicate nonahydrate solution with a mass fraction of 40% dropwise to the flask, stir for 2 to 3 hours, cool to room temperature naturally, and discharge to obtain a solid-liquid mixture; filter the solid-liquid mixture with a vacuum filter to remove The filtrate obtains the sucti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com