Pressing head and device for achieving densification of spray deposition porous panel and application thereof

A technology of spray deposition and densification, which is applied in the field of densification processing of metal materials, can solve the problems of poor densification forming effect, difficult forming, and difficult forming of slabs, and achieve continuous deformation, good densification effect, and prevent cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

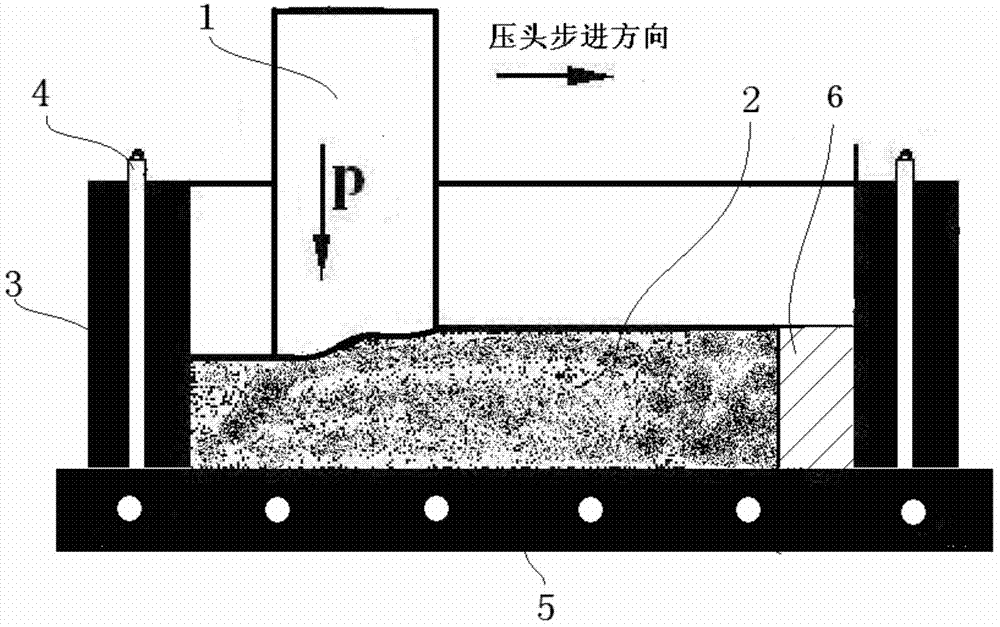

[0047] Follow the technical scheme of the present invention, refer to figure 1 and figure 2 , the specific structural dimensions of the spray-deposited metal slab densification device implemented are as follows:

[0048] The steel mold is a square frame without a bottom plate, the inner wall size is 500mm x 110mm x 180mm, the thickness of the steel mold is 60mm, and it is made of 45 steel. On the side wall of the steel mold, 16 single power cables are evenly arranged in the vertical direction. It is a 1kW stainless steel electric heating rod, and the outer diameter of the electric heating rod is 20mm.

[0049] The size of the bottom plate is 700mm×300mm×180mm in length×width×thickness. The thickness of the steel mold is 60mm. The diameter is 20mm.

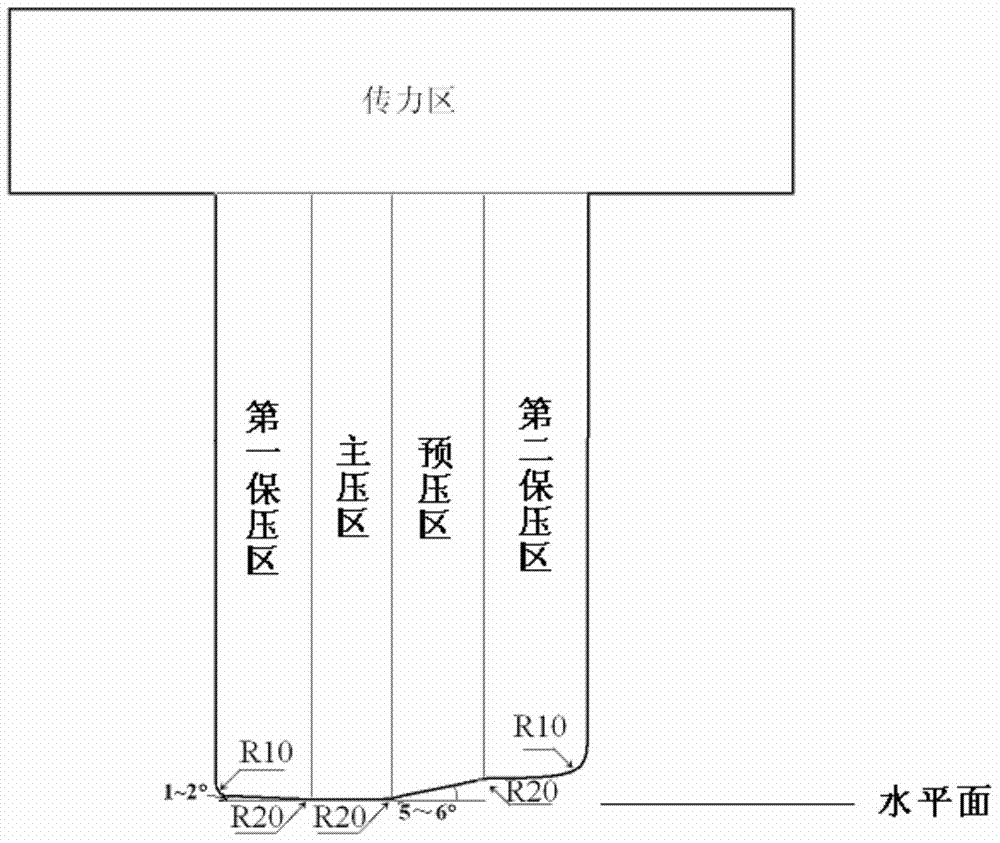

[0050] The indenter of this embodiment is made of 45 steel, the length × width × thickness of the indenter is 110mm × 90mm × 300mm, the height of the indenter meets the height from the main pressure surface of the indenter to t...

Embodiment 2

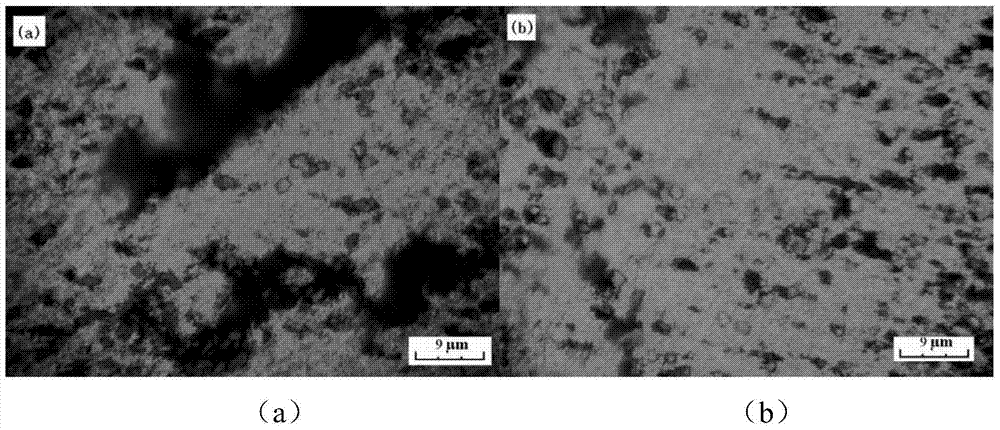

[0059] Utilize the device in embodiment 1 and crucible mobile spray co-deposition device to prepare SiC P / Al-8.5Fe-1.3V-1.7Si composite slab.

[0060] In this embodiment, mechanically crushed β-SiC is selected as the reinforcing particles, with an average particle size of about 10 μm.

[0061] The spray-deposited slab is first sawn into a length×width×thickness of 460mm×120mm×30mm, and then planed to process a slab with a length×width×thickness of 450mm×110mm×(20-25)mm. Place the bottom plate of the compact device on the 6300kN press platform so that the bottom plate is located in the central area of the press table, and then place the steel mold symmetrically on the bottom plate. The slab is placed flat in the pressing steel mold, and a pure aluminum slab with a length×width×thickness of 50mm×110mm×15mm is put into one end of the slab. Install the pressure head used for pressing on the T-shaped slot of the upper slider of the press. The direction of the T-shaped slot is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com