Aluminum foil suitable for lithium ion battery and preparation method thereof

A lithium-ion battery and aluminum foil technology, which is applied in the field of metal aluminum, can solve the problems that the tensile strength and conductivity of aluminum materials cannot be satisfied, the cost of aluminum materials remains high, and the conductivity of aluminum alloys is affected, so as to increase the strength and mechanical properties of the aluminum alloy. Performance indicators, high cupping value, and good elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

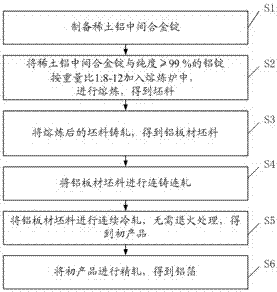

[0048] See figure 1 , The present invention provides a method for preparing aluminum foil suitable for lithium ion batteries, including:

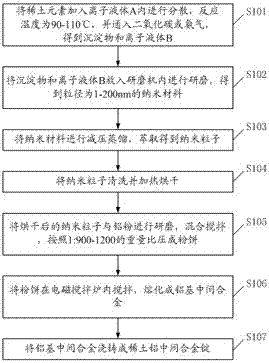

[0049] S1. Preparation of rare earth aluminum master alloy ingots: Put rare earth elements with a purity of ≥99% into a diamond grinder for grinding to obtain nano-rare earth materials with a particle size of 1-200nm, and combine the nano-rare earth materials with purity ≥99% and copper content The aluminum powder less than 0.005% is ground, mixed and stirred, and pressed into a powder cake according to the weight ratio of 1:900-1200, and then the powder cake is melted and cast into a rare earth aluminum intermediate alloy ingot;

[0050] S2. Add rare earth aluminum master alloy ingots and aluminum ingots with a purity of ≥99% into a smelting furnace at a weight ratio of 1:8-12 to perform smelting to obtain billets;

[0051] Preferably, the melting conditions are: 6 hours in a 700°C melting furnace.

[0052] Smelting is to remove gas and slag, redu...

Embodiment 1

[0115] 1. Preparation of rare earth aluminum master alloy ingots:

[0116] 1. Add the carbonate of praseodymium to 1-ethyl-3-methylimidazole cyanomethyl salt for dispersion, and the weight ratio of praseodymium to 1-ethyl-3-methylimidazole cyanomethyl salt is 1:1 , The reaction temperature is 90℃, and carbon dioxide is introduced to obtain the precipitate and ionic liquid B. The generated gas is introduced into the soda lime absorption tank and absorbed by the soda lime to make fertilizer;

[0117] 2. Put the precipitate and ionic liquid B into a diamond grinder for grinding, and grinding for 1 hour to obtain nanomaterials with a particle size of 1-200nm;

[0118] 3. The nanomaterials are distilled under reduced pressure and extracted to obtain nanoparticles;

[0119] 4. Wash the nanoparticles with deionized water and heat and dry them at a temperature of 100°C;

[0120] 5. Grind the dried nanoparticles and aluminum powder, mix and stir, and press them into a powder cake according to a...

Embodiment 2

[0129] 1. Preparation of rare earth aluminum master alloy ingots:

[0130] 1. Add the ammonium salt of neodymium to 1-butyl-3-methylimidazole hexafluorophosphate for dispersion. The weight ratio of neodymium to 1-butyl-3-methylimidazole hexafluorophosphate is 1:1. The reaction temperature is 95°C, and ammonia gas is introduced to obtain precipitate and ionic liquid B. The generated gas is introduced into the soda lime absorption tank and absorbed by the soda lime to make fertilizer;

[0131] 2. Put the precipitate and ionic liquid B into a diamond grinder for grinding, and grinding for 2 hours to obtain nanomaterials with a particle size of 1-200nm;

[0132] 3. The nanomaterial is distilled under reduced pressure, and the nanoparticle is obtained by extraction.

[0133] 4. Wash the nanoparticles with deionized water and heat and dry them at a temperature of 110°C

[0134] 5. Grind the dried nanoparticles and aluminum powder, mix and stir, and press into a powder cake according to the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com