Normalized cryogenic steel at temperature of -50 DEG C and manufacturing method thereof

A low-temperature steel and normalizing technology, applied in the field of construction, can solve problems such as low strength and coarse ferrite grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

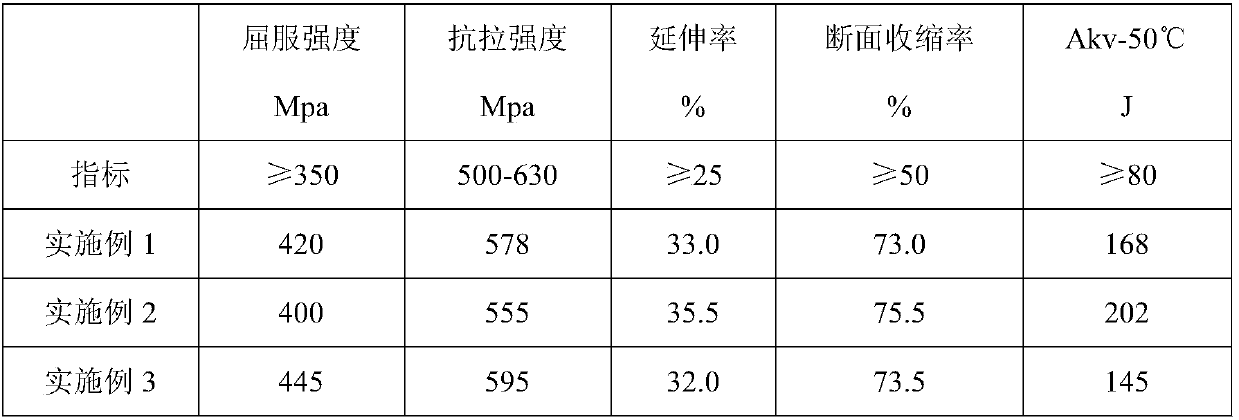

Examples

Embodiment 1

[0041]100 tons of oxygen top-blown converter is used for smelting, and the position of the gun is well controlled during the blowing process to achieve good slag in the process and coordinated carbon temperature;

[0042] The reduced slag made by LF furnace is desulfurized to reduce inclusions and adjust the composition. The holding time of VD furnace is 18min. Determination of H, O content, [H] = 1.0ppm, [O] = 15ppm;

[0043] Mold slag is selected for continuous casting, the whole process is protected and poured, and the billet size is 300mm;

[0044] The slab enters the slow cooling pit for slow cooling, and after the slow cooling, it is quickly cleaned up, and the cleaning temperature is 180°C;

[0045] Two-stage controlled rolling, the first-stage rolling temperature is 1100°C, the second-stage rolling temperature is 900°C, air-cooled after rolling, and the thickness of the steel plate is 30mm;

[0046] Heat treatment: normalizing + tempering heat treatment is adopted, ...

Embodiment 2

[0048] 100 tons of oxygen top-blown converter is used for smelting, and the position of the gun is well controlled during the blowing process to achieve good slag in the process and coordinated carbon temperature;

[0049] The reduced slag made by LF furnace is desulfurized to reduce inclusions and adjust the composition. The holding time of VD furnace is 15min. Determination of H, O content, [H] = 1.2ppm, [O] = 18ppm;

[0050] Mold slag is selected for continuous casting, the whole process is protected and poured, and the billet size is 300mm;

[0051] The slab enters the slow cooling pit for slow cooling, and after the slow cooling, it is cleaned by rushing temperature, and the cleaning temperature is 170°C;

[0052] Two-stage controlled rolling, the first-stage rolling temperature is 1080°C, the second-stage rolling temperature is 910°C, air-cooled after rolling, and the thickness of the steel plate is 30mm;

[0053] Heat treatment, using normalizing + tempering heat tre...

Embodiment 3

[0055] 100 tons of oxygen top-blown converter is used for smelting, and the position of the gun is well controlled during the blowing process to achieve good slag in the process and coordinated carbon temperature;

[0056] The reduced slag made by LF furnace is desulfurized to reduce inclusions and adjust the composition. The holding time of VD furnace is 17min. Determination of H, O content, [H] = 1.0ppm, [O] = 16ppm;

[0057] Mold slag is selected for continuous casting, the whole process is protected and poured, and the billet size is 300mm;

[0058] The slab enters the slow cooling pit for slow cooling, and after the slow cooling, it is cleaned at a temperature of 165°C;

[0059] Two-stage controlled rolling, the first-stage rolling temperature is 1060°C, the second-stage rolling temperature is 890°C, air-cooled after rolling, and the thickness of the steel plate is 30mm;

[0060] The heat treatment adopts normalizing + tempering heat treatment, put the steel plate at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com