High strength rotor shaft forging for high voltage motor and heat treatment machining method

A high-voltage motor, processing method technology, used in heat treatment furnaces, heat treatment equipment, furnace types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

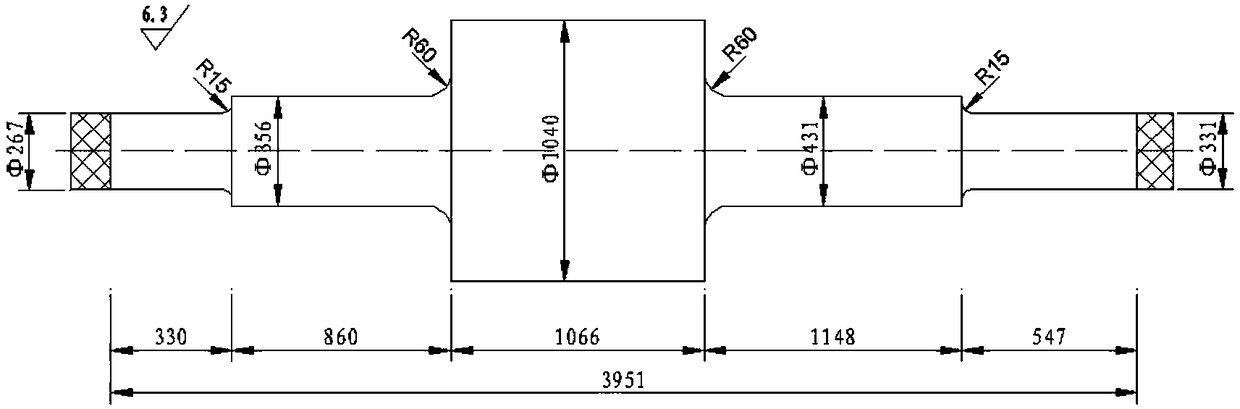

[0019] Embodiment 1: with reference to attached Figure 1-5 . A high-strength rotor shaft processing method for a high-voltage motor, (1) The mass percentage of the rotor shaft material: C 0.30-0.36%, Si0.17-0.37%, Mn0.25-0.50%, P and S≤0.020%, Cr1 .30-1.60%, Mo0.20-0.35%, Ni 1.30-1.60%, V0.04-0.10%;

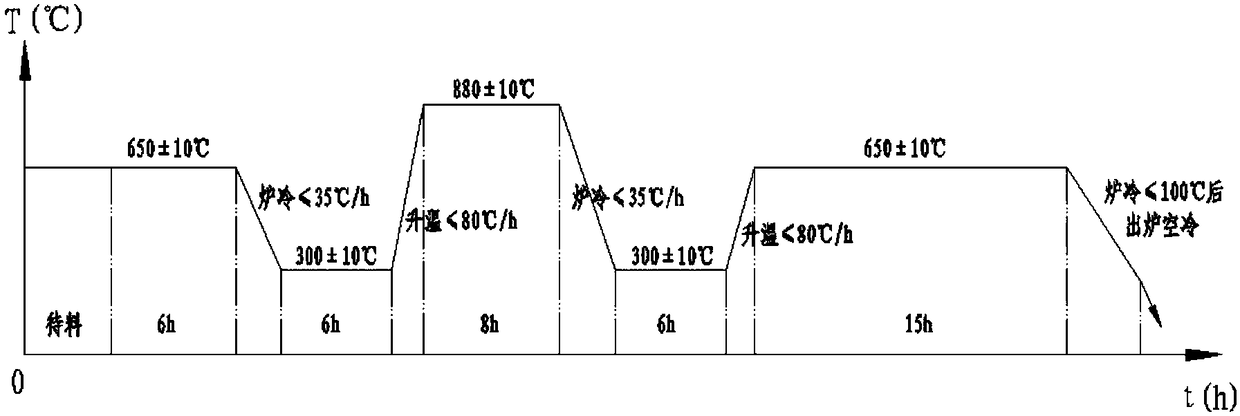

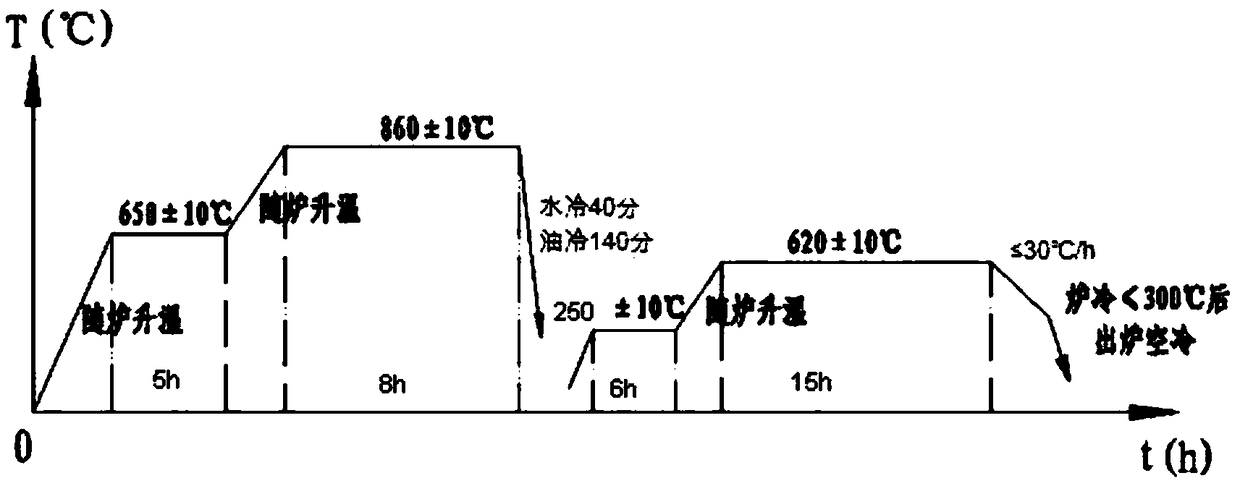

[0020] (2) Heat treatment and tempering after forging:

[0021]a. Post-forging heat treatment: After the forging of the forging is completed, it should be air-cooled to an annealing furnace where the surface of the forging is 650°C, and kept at 650°C for 6 hours to eliminate the stress generated during forging, and then the heat treatment should be less than 35°C / h The cooling rate is cooled to 300°C and kept at 300°C for 6 hours to fully transform the austenite structure of the forging; after the heat preservation at 300°C is completed, it is heated to 880°C at a speed of no more than 80°C / h and held at 8 hours. After fully austenitizing the inside of the workpiece, furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com