Heat treatment normalizing process

A normalizing and process technology, applied in the field of heat treatment normalizing process, can solve problems such as non-compliance with product design requirements, large gaps, and difficult control and realization of process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is implemented through the following steps:

[0019] 1. Use a mesh belt type normalizing furnace to heat in the range of 900-920 ℃, and keep warm for 60-80 minutes;

[0020] 2. Three special fans are used for forced air cooling on the cooling track, and the air supply volume of a single fan is 4000-6000m 3 / h;

[0021] 3. Adjust the speed of the cooling track so that the surface temperature of the material after cooling out of the water is lower than 200°C, and the cooling time is controlled within 2 minutes;

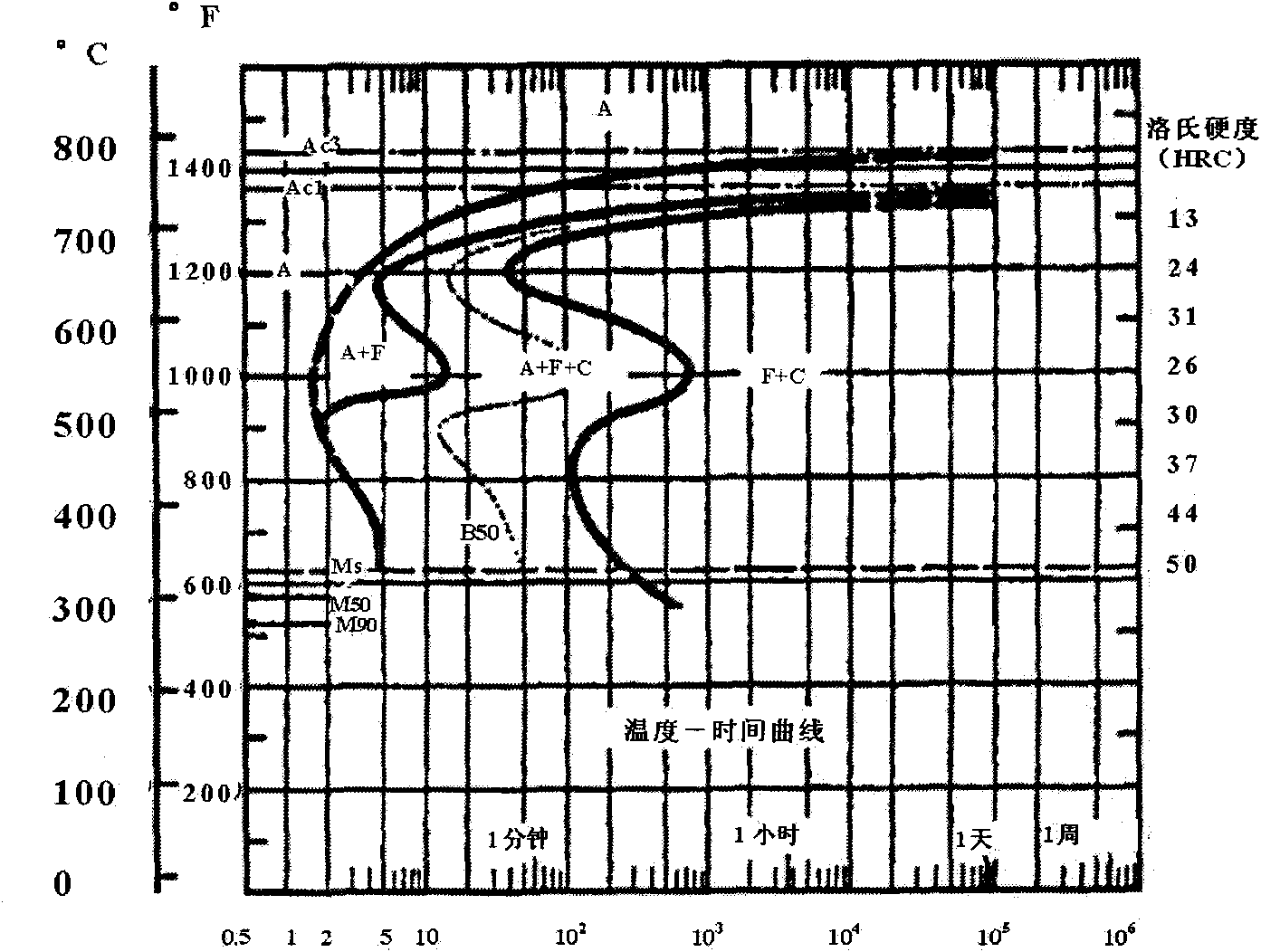

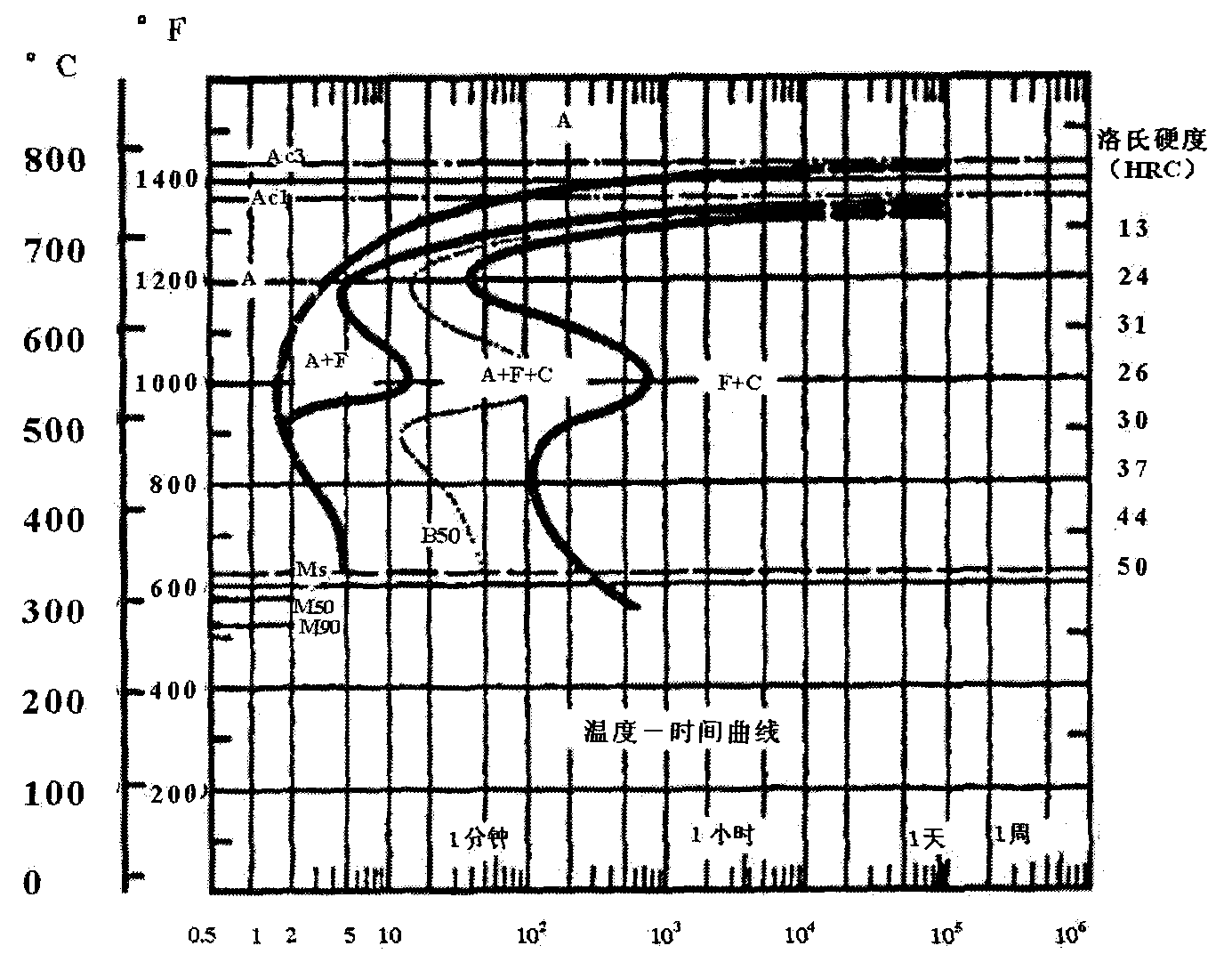

[0022] 4. Check the normalizing hardness with the Rockwell hardness, and select the tempering process in step 5 according to the normalizing hardness;

[0023] 5. The tempering temperature is selected from the table below according to the normalizing hardness, and the holding time is 60-90 minutes;

[0024] Hardness after normalizing (HRC)

Tempering temperature range (℃)

26~30

570~590

[0025] Ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com