Method for preparing nano diamond composite coating by millisecond laser cladding

A nano-diamond and composite coating technology, which is applied in the coating process and coating of metal materials, can solve the problems of loose coating structure, slow deposition speed, and high cladding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

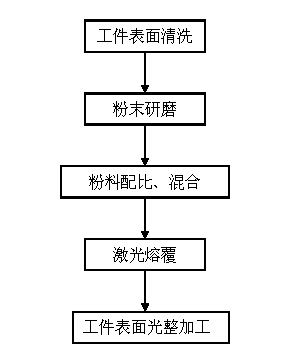

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with specific implementation examples.

[0020] Use sandpaper to grind and polish the oxide layer on the surface of the nickel-based alloy workpiece, then use emulsifier, absolute ethanol to degrease, clean, and dry. Add 10% fine-structure microcrystalline graphite powder and 2%-5% fine-structure catalyst powder to nickel-based alloy powder, place the mixed powder in deionized water, and use an ultrasonic cleaning machine to generate ultrasonic waves with a frequency of 40-58KHz for vibration Mix for 30 minutes, and then dry the mixture to make a pre-layer powder for cladding. Put the nickel-based alloy workpiece to be clad into the vacuum chamber, fix and clamp it horizontally on the workbench, put the obtained preset layer powder into the automatic powder feeding device, and the vacuum degree reaches 10 -3 ~10 -4 Pa. Turn on the millisecond laser, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com