Wear-resistant layer fusion composite technology of scraper conveyor and scraper conveyor with wear-resistant layer

A technology of scraper conveyor and compound process, which is applied in conveyors, manufacturing tools, transportation and packaging, etc., can solve problems affecting production continuity and construction difficulty, failure to achieve good wear resistance, and affecting normal operation of equipment, etc. Achieve the effects of avoiding thermal deformation, reducing component size changes, and reducing cladding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

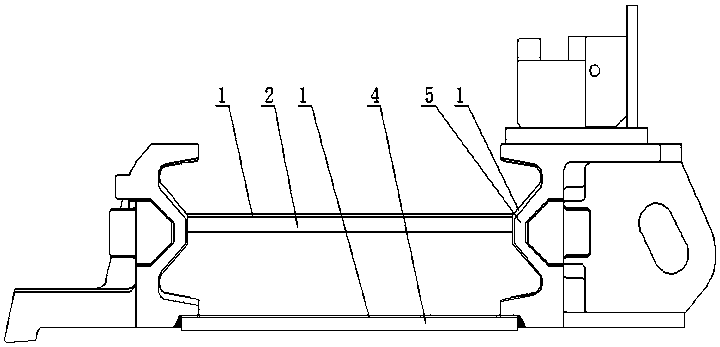

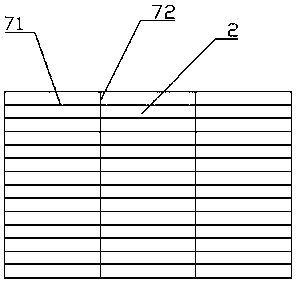

[0042] like figure 1 , figure 2 and image 3 The shown scraper conveyor with a wear-resistant layer is a mature prior art, including a bottom plate 4 , a middle plate 2 and an E-shaped groove 5 . In the present application, on the basis of the prior art, a wear-resistant layer 1 is provided on the bottom plate 4, the middle plate 2 and the E-shaped groove edge 5, and the wear-resistant layer 1 is provided to enhance the wear resistance of the scraper conveyor, so that the scraper Conveyor is more suitable for coal mine transportation.

[0043] Wherein, the setting positions of the wear-resistant layer 1 are the upper surfaces of the bottom plate 4, the middle plate 2 and the E-shaped groove edge 5; the thickness of the wear-resistant layer 1 is 3-5mm, preferably 4mm. The wear resistance of the bottom plate 4, the middle plate 2 and the E-shaped groove 5 is enhanced, and on the other hand, the normal operation of the bottom plate 4, the middle plate 2 and the E-shaped groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com