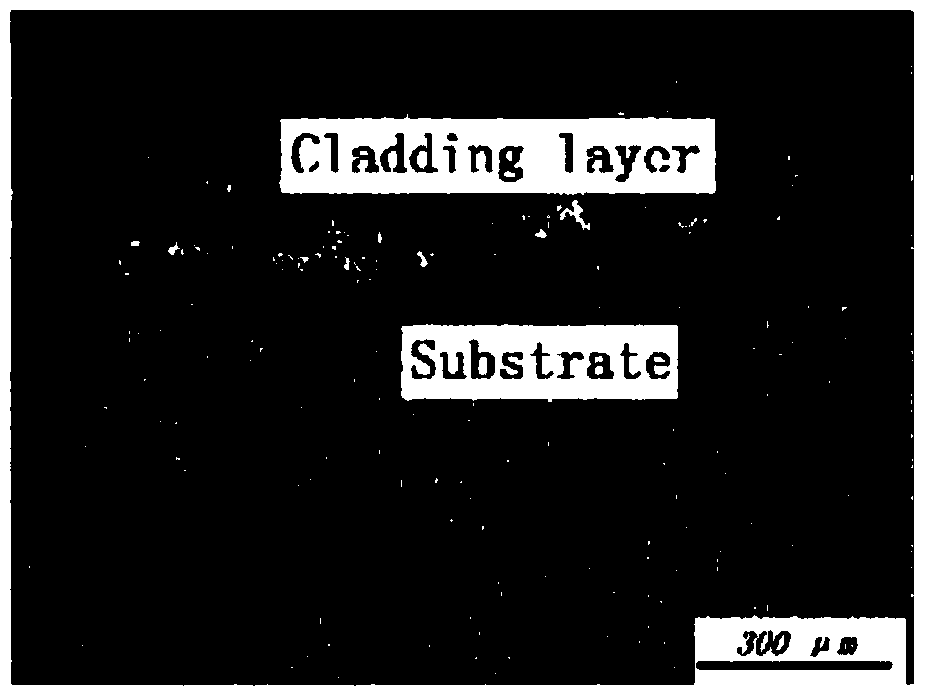

Laser cladding process on the surface of copper substrate

A laser cladding and matrix technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of high dilution rate between cladding layer and matrix, which cannot well meet industrial production, and high thermal deformation rate of matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] (1) Laser cladding process on copper substrate surface

[0032] A laser cladding process on the surface of a copper substrate of the present invention comprises the following steps:

[0033] A. Polishing; use polishing equipment such as sandpaper or a polishing machine to polish the surface of the copper substrate to make the surface of the copper substrate smooth and shiny;

[0034] B. Decontamination: Use the decontamination agent acetone to clean the surface of the copper substrate to remove oil stains and other pollutants on the surface of the copper substrate;

[0035] C. Laser cladding: use a laser coaxial powder feeder to feed the cladding alloy material with a particle size of -150 to 300 mesh into the surface of the copper substrate, and at the same time use a pulsed Nd:YAG laser for laser cladding layer by layer to form cladding The thickness of the layer is between 0.1-2.5mm; wherein, in terms of mass percentage, the composition of the wear-resistant and hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com