Preparation method of aluminum boron intermediate alloy wire for electrician aluminum melt purification

A melt purification and master alloy technology, which is applied in the field of preparation of aluminum-boron master alloy wire for electrical aluminum melt purification, can solve the problems of increasing equipment investment, poor flow performance, affecting production efficiency, etc., to improve the evolution effect, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with examples.

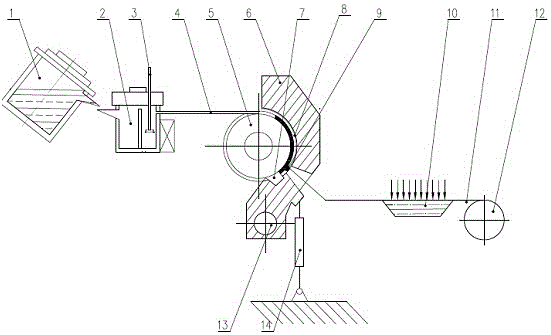

[0016] figure 1 It is a schematic diagram of the process flow of the present invention. In the figure, 1 is a melting furnace; 2 is a heat preservation bag; 3 is an agitator; 4 is a launder; 9 is an extrusion die; 10 is a cooling water tank; 11 is a finished product; 12 is a coiler; 13 is a rotating shaft; 14 is a hydraulic cylinder.

[0017] Now illustrate an example of the present invention in conjunction with accompanying drawing.

[0018] The technological method of the present invention is mainly realized through a smelting furnace, a holding furnace, a continuous casting extruder, a coiler, and the like. The block block 7 and the extrusion die 8 of the extrusion machine are arranged on the outer surface of the extrusion wheel 5 under the extrusion shoe 6 to be processed with an annular groove capable of holding the alloy liquid. Under the action of the hydraulic cylinder 14,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com