Chiller coating for molding of green-sand-casting ductile iron castings and application method thereof

A technology for casting ductile iron and chilled iron coating, which is applied in the field of chilled iron coating for wet-type casting ductile iron castings, which can solve the problems of a large amount of harmful gas and dust, easy to produce pore defects, etc., and achieve fine internal structure and simple preparation method Fast, gas-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

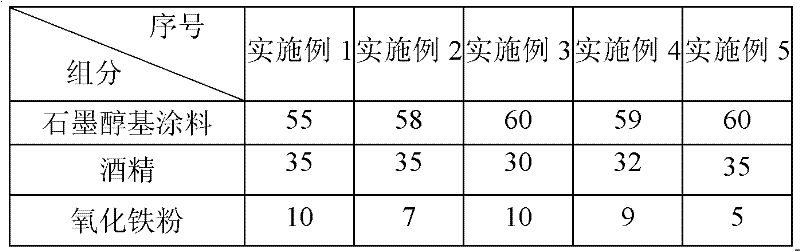

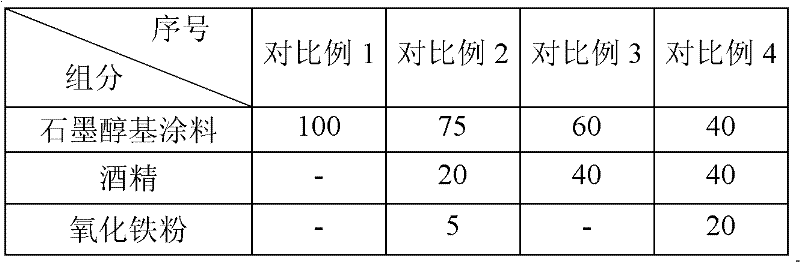

[0013] The mass percentage components of the cold iron coating for the molding of the green cast ductile iron casting are shown in Table 1, and Example 3 is the best implementation mode.

[0014] Table 1 Examples 1-5 Cold iron coatings for wet casting ductile iron castings (by mass percentage)

[0015]

[0016] Graphite alcohol-based paint, alcohol and iron oxide powder are put into a mixer in proportion, and stirred evenly at room temperature, that is, the chilled iron paint for wet casting ductile iron castings in Examples 1-5. When pouring, evenly brush a layer of uniformly mixed chilled iron paint on the surface of the chilled iron in the molding sand. The thickness of the chilled iron paint is 1-2mm. It is heated and dried before pouring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com