Extruding and die-casting process for electric steering shell with high strength and low porosity

An electric steering and die-casting technology, applied in the field of die-casting, can solve the problems of poor internal quality, substandard porosity, shrinkage cavity, and large local wall thickness, and achieve the effect of improving product strength, avoiding shrinkage cavity defects, and fine internal organization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

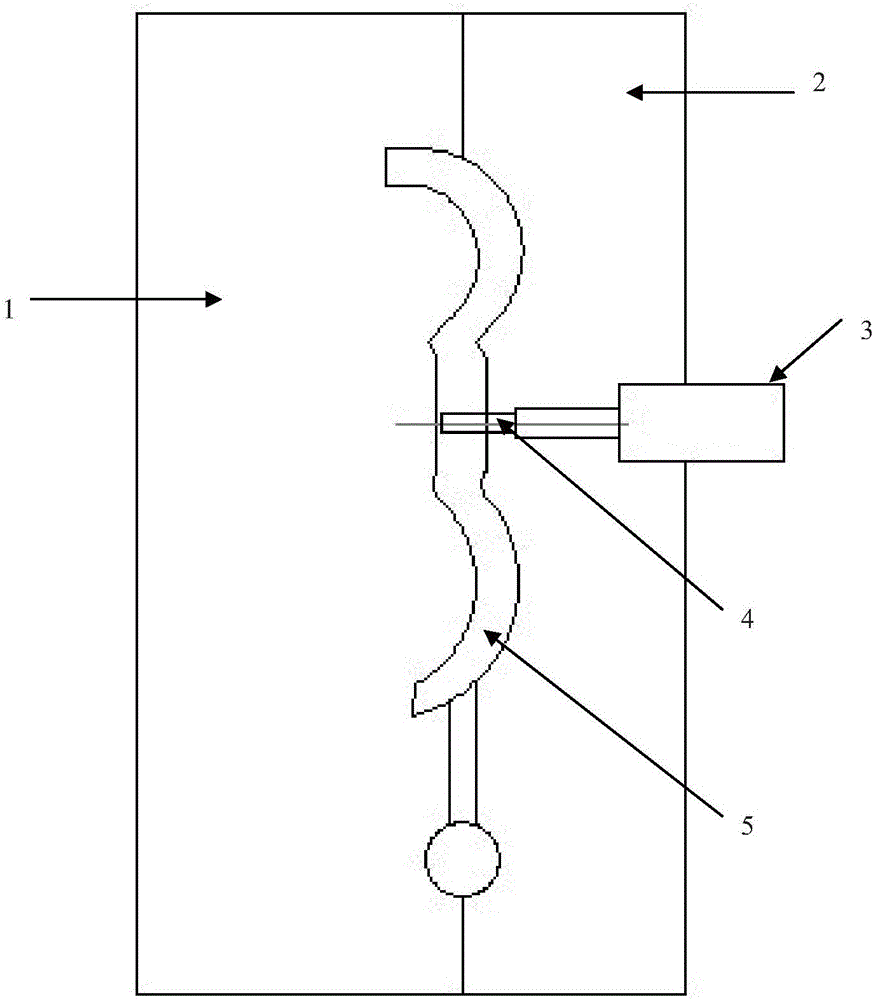

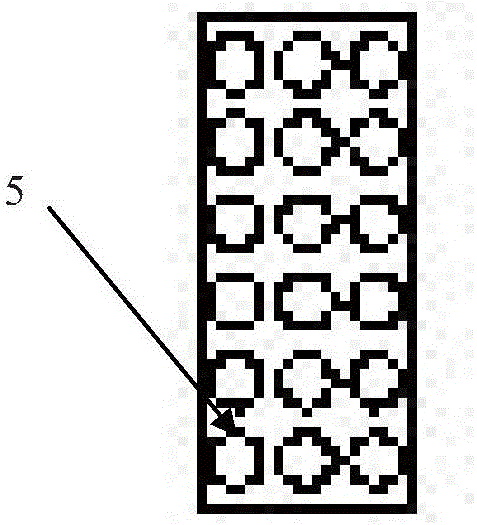

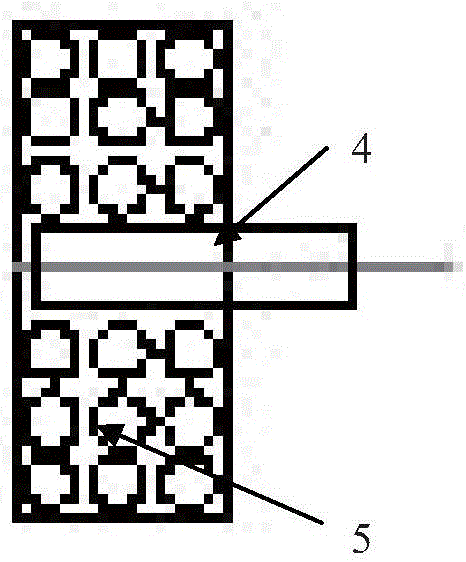

[0029] The invention provides a high-strength and low-porosity electric steering casing extrusion die-casting process, comprising the following steps:

[0030] (1) each material is 8% Si by weight percentage, 0.45% Mg, 1.0% Fe, 3.0% Cu, 0.40% Mn, 0.35% Ni, 1.0% Zn, 0.25% Pb, 0.20% Sn; 0.15% Ti, 0.10% Cr, and the rest is Al added to the die-casting melting furnace;

[0031] (2) The smelting temperature of the die-casting melting furnace is set to 700-750°C, and the temperature starts to rise, and when the temperature of the die-casting melting furnace rises above 710°C, the refining agent is added in an amount of 0.3-0.5% of the total weight of the material for refining;

[0032] (3) While adding the refining agent in step (2), use a degasser (99.99% argon) to perform a degassing operation for 10-20 minutes, take a sample, and use a spectral analysis device to detect the composition of the sample, and the composition is qualified Stand still for 10-15 minutes to prepare for di...

Embodiment 2

[0040] In this embodiment, the high-strength low-porosity electric steering housing is composed of the following components in weight percentage: 7% Si, 0.05% Mg, 0.5% Fe, 2.0% Cu, 0.1% Mn, 0.25% Ni, 0.2% Zn, 0.33% Pb, 0.15% Sn; 0.15% Ti, 0.06% Cr, and the balance is Al.

[0041] The above-mentioned high-strength and low-porosity electric steering casing is obtained by the same method as in Example 1.

Embodiment 3

[0043] In this embodiment, the high-strength low-porosity electric steering housing is composed of the following components in weight percentage: 10% Si, 0.55% Mg, 1.5% Fe, 4.0% Cu, 0.55% Mn, 0.55% Ni, 1.2% Zn, 0.35% Pb, 0.25% Sn; 0.25% Ti, 0.15% Cr, and the balance is Al.

[0044] The above-mentioned high-strength and low-porosity electric steering casing is obtained by the same method as in Example 1.

[0045]The refining agent used in Examples 1-3 may be HYJD-1F HYJD-2F refining agent, such as produced by Zhongshan Huayu Nonferrous Metallurgical Materials Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com