Method for manufacturing automobile control arm body blank

A technology of automobile control arm and manufacturing method, which is applied in the field of manufacture of automobile control arm body blanks, can solve the problems of long production cycle, material waste, high energy consumption, etc., and achieve shortened production cycle, small machining allowance and high material utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

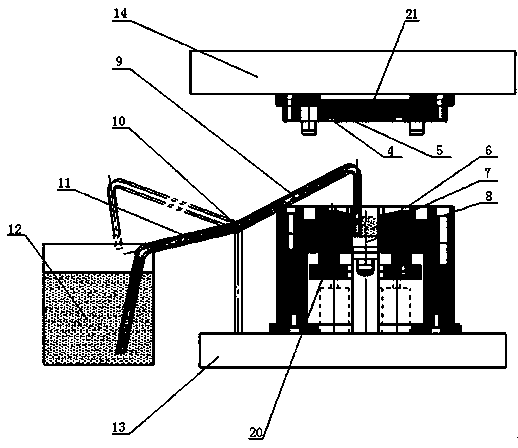

[0034] A method for manufacturing an A356 aluminum alloy automobile control arm body blank for liquid die forging with one die and two cavities, comprising the following steps:

[0035]1) Melting alloy melt: use waste aluminum alloy as raw material to prepare Al-Si-Mg series A356 cast aluminum alloy, after the chemical composition, temperature and purity meet the requirements, transfer it to the holding furnace 12 for heat preservation; The above-mentioned holding temperature is 680°C; the above-mentioned scrap aluminum alloys are recovered Al-Si, Al-Mg and Al-Cu series waste aluminum alloy materials; the above-mentioned Al-Si-Mg series cast aluminum alloys are produced in Based on the A356 aluminum alloy, the alloy is improved by adding 0.2% of the light rare earth element lanthanum for alloying;

[0036] 2) Low-pressure pouring aluminum alloy liquid: such as image 3 As shown, a pressure of 0.15 MPa is applied to the casting aluminum alloy liquid in the holding furnace 12, ...

Embodiment 2

[0041] A method for manufacturing a molded three-cavity A357 aluminum alloy automobile control arm body blank, comprising the following steps:

[0042] 1) Melting alloy melt: use waste aluminum alloy as raw material to prepare Al-Si-Mg series cast aluminum alloy, and after the chemical composition, temperature and purity meet the requirements, transfer it to the holding furnace 12 for heat preservation. The holding temperature is 700°C; the waste aluminum alloys are recycled Al-Si, Al-Mg and Al-Cu waste aluminum alloys; the Al-Si-Mg cast aluminum alloys are A357 aluminum alloy.

[0043] 2) Low-pressure pouring aluminum alloy liquid: such as image 3 As shown, a pressure of 0.3 MPa is applied to the casting aluminum alloy liquid in the holding furnace 12, so that the aluminum alloy liquid is poured into the pressure chamber 5 in the center of the metal mold through the infusion pipes 9, 10, and 11 to a set height, and the pressure is released. The remaining aluminum alloy liq...

Embodiment 3

[0048] A method for manufacturing a molded four-cavity ZL114A aluminum alloy automobile control arm body blank, comprising the following steps:

[0049] 1) Melting alloy melt: use waste aluminum alloy as raw material to prepare Al-Si-Mg cast aluminum alloy, after the chemical composition, temperature and purity meet the requirements, transfer it to the holding furnace 12 for heat preservation; The heat preservation temperature is 720°C; the scrap aluminum alloys are recovered Al-Si, Al-Mg and Al-Cu series waste aluminum alloy materials; the Al-Si-Mg cast aluminum alloys are made in ZL114A The alloy improved by alloying with 0.5% rare earth element cerium on the basic condition;

[0050] 2) Low-pressure pouring aluminum alloy liquid: such as image 3 As shown, a pressure of 0.5 MPa is applied to the casting aluminum alloy liquid in the holding furnace 12, so that the aluminum alloy liquid is poured into the pressure chamber 5 in the center of the metal mold through the infusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com