Aluminum alloy 62Sn spectral standard sample and preparation method thereof

A spectral standard sample and standard sample technology, which is applied in the field of aluminum alloy 62Sn spectral standard sample and preparation, can solve the problems of chemical composition analysis limitation, uncontrollable content, etc., achieve the effect of fine structure, improve production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] The invention provides a method for preparing an aluminum alloy 62Sn spectrum standard sample, comprising:

[0093] 1) Al, Si, Fe, Cu, Mn, Cr, Zn, Mg and Ti are mixed and heated until melted to obtain the first alloy solution;

[0094] 2) adding molten Bi and molten Sn to the first alloy solution, and adjusting Bi and Sn to meet the content requirements of the spectral standard sample, to obtain an alloy solution;

[0095] 3) casting the alloy solution to obtain an ingot;

[0096] 4) The ingot is homogenized and heat-treated and extruded to obtain a standard sample of the aluminum alloy 62Sn spectrum.

[0097] Al, Si, Fe, Cu, Mn, Cr, Zn, Mg and Ti are mixed and heated to melt to obtain a first alloy solution; the heating temperature is 750-780°C, preferably 760°C. The Al is preferably aluminum 9970.

[0098] In order to ensure that Mg can be well dissolved in the alloy solution, the present invention adopts the distribution adjustment chemical composition method, pre...

Embodiment 1

[0183] Preparation of aluminum alloy 62Sn standard sample 62Sn-1

[0184] 1) Add Al, Si, Fe, Cu, Mn, Cr, Zn and Ti into the furnace according to the composition percentage in Table 1, heat to 760°C, stir, and adjust Si, Fe, Cu, Mn, Cr, Zn and Ti to Meet the content requirements of the spectral standard sample, and obtain the alloy solution without adding Mg;

[0185] 2) Add Mg to the alloy solution without adding Mg according to the composition percentage in Table 1, stir, and adjust the Mg to meet the content requirements of the spectral standard sample to obtain the first alloy solution.

[0186] 3) Add molten Bi and molten Sn to the first alloy solution according to the composition ratio in Table 1, stir, and adjust Bi and Sn to meet the content requirements of the spectral standard sample to obtain the alloy solution;

[0187] 4) Under stirring conditions, the alloy solution is cast by semi-continuous casting at a temperature of 745-755°C, a casting speed of 65-75mm / min, ...

Embodiment 2~5

[0191] The preparation method of Examples 2-5 is the same as that of Example 1, see Table 1 for specific composition percentages, and prepare aluminum alloy 62Sn standard samples 62Sn-1-62Sn-5.

[0192] Table 1 Mass percentage (wt%) of aluminum alloy 62Sn spectrum standard sample composition in Examples 1-5

[0193]

[0194]

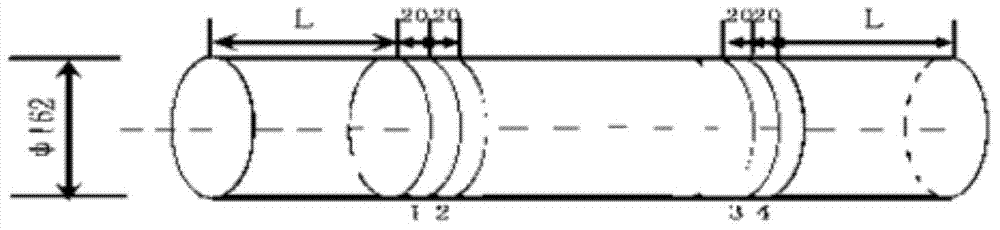

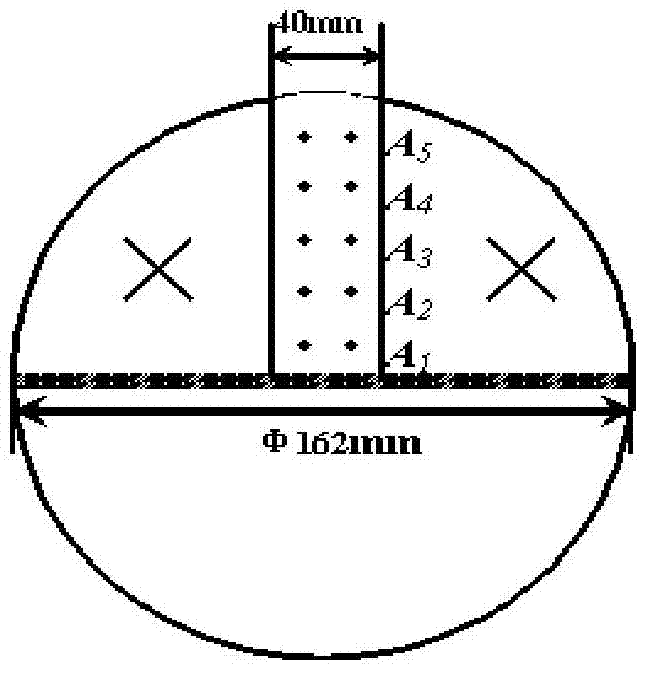

[0195] Metallographic structure inspection and component segregation inspection are carried out to the ingot that step 4 obtains in embodiment 1~5, the sampling of inspection test piece is as follows: figure 1 as shown, figure 1 Schematic diagram of the sampling positions of the metallographic test piece and the segregation test piece of the ingot provided by the present invention, wherein, L is 120-220mm, 1 and 4 are the cutting positions of the metallographic test piece, and 2 and 3 are the component segregation test pieces. The cutting part of the slice.

[0196] By carrying out metallographic high-magnification and metallographic low-magnific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com