Metal plastic swaging forming method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A metal plastic extrusion forging method, comprising the following steps:

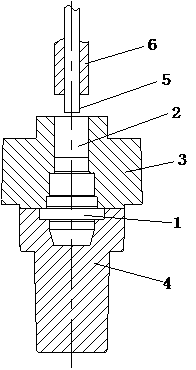

[0029] (1) Prepare extrusion forging equipment (such as figure 1 shown), the extrusion forging equipment has an openable and closed cavity 1 and a first extrusion channel 2 communicating with the cavity 1; the openable and closed cavity 1 is formed by the upper The mold 3 and the lower mold 4 are formed, and the first extrusion forging channel 2 is arranged on the upper mold 3;

[0030] (2) Steps of feeding and extrusion, to open the cavity 1, put the workpiece blank into the cavity 1 or the first extrusion forging channel 2, and close the cavity 1 after closing the mold, and adopt the extrusion end face size smaller than the first extrusion forging The first punching part 5 of the cross-sectional size of the channel 2 is inserted into the first extrusion forging channel 2 to squeeze holes on the workpiece blank, and the workpiece blank produces a plastic deformation;

[0031] (3) In the formi...

Embodiment 2

[0039] A metal plastic extrusion forging method, comprising the following steps:

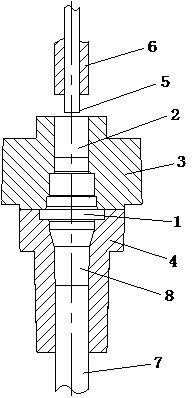

[0040] (1) Prepare extrusion forging equipment (such as figure 2 shown), the extrusion forging equipment has an openable and closed cavity 1 and a first extrusion channel 2 communicating with the cavity 1; the openable and closed cavity 1 is formed by the upper The mold 3 and the lower mold 4 are formed, and the first extrusion forging channel 2 is arranged on the upper mold 3 . The extruding and forging molding equipment also has a second extruding hole member 7 and a second extruding forging channel 8 communicated with the cavity 1, the second extruding forging channel 8 is arranged in the lower die 4, and the cross-sectional size of the second extruding hole member 7 is the same as that of the first forging channel. The cross-sectional dimensions of the two extrusion forging channels 8 are consistent, and the second extrusion forging channel 8 is coaxial and opposite to the first extrusion ...

Embodiment 3

[0049] A metal plastic extrusion forging method, comprising the following steps:

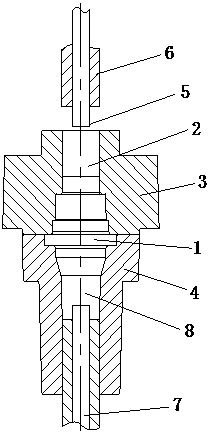

[0050] (1) Prepare extrusion forging equipment (such as image 3 shown), the extrusion forging equipment has an openable and closed cavity 1 and a first extrusion channel 2 communicating with the cavity 1; the openable and closed cavity 1 is formed by the upper The mold 3 and the lower mold 4 are formed, and the first extrusion forging channel 2 is arranged on the upper mold 3 . The extruding and forging molding equipment also has a second extruding hole member 7 and a second extruding forging channel 8 communicated with the cavity 1, the second extruding forging channel 8 is arranged in the lower die 4, and the cross-sectional size of the second extruding hole member 7 is the same as that of the first forging channel. The cross-sectional dimensions of the two extrusion forging channels 8 are consistent, and the second extrusion forging channel 8 is coaxial and opposite to the first extrusion f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com